Preparation technology for graphene nanosheet thin film

A technology of nano-chips and preparation process, which is applied in the field of preparation technology of graphene nano-chips with two-dimensional highly ordered arrangement to form films, can solve the problem of low order degree of graphene nano-chips, high process requirements and difficulty in production. Industrial application and other issues, to achieve the effect of simple and easy process, simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

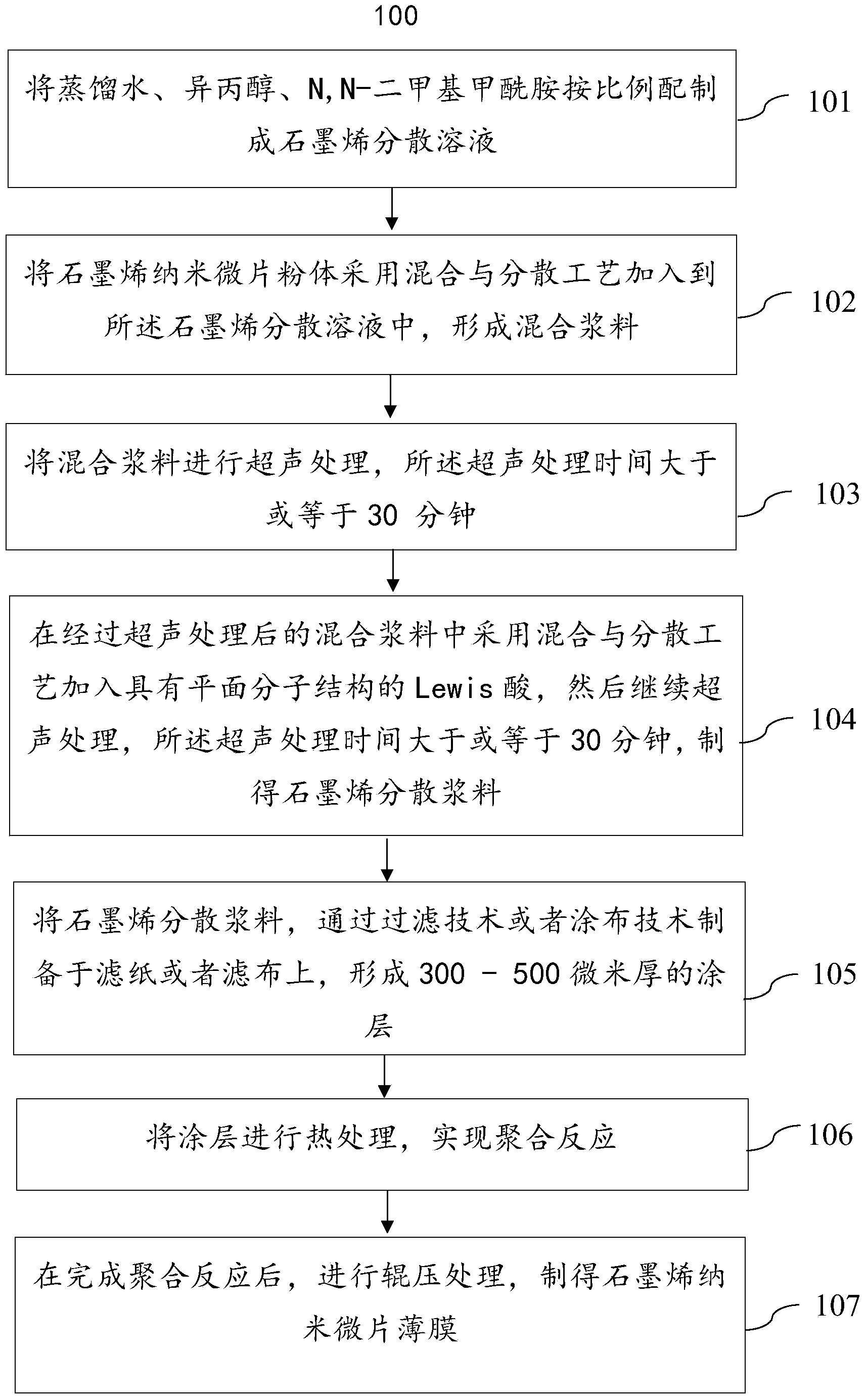

[0052] 1. Preparation of graphene dispersion solution: Distilled water, isopropanol (IPA), N,N-dimethylformamide (DMF) according to the volume ratio of isopropanol:N,N-dimethylformamide is 1: 2-1:10, the volume ratio of isopropanol and N,N-dimethylformamide:distilled water is 1:1-3:1 to prepare a graphene dispersion solution, and use ammonia water, acetic acid, dilute hydrochloric acid, hydrogen One or more of sodium oxide solution and tetramethylamine to adjust the pH value between 6 and 11;

[0053] 2. Add an appropriate amount of graphene nano-chip powder to the prepared dispersion solvent to form a mixed slurry;

[0054] 3. Ultrasonic treatment of the mixed slurry (ultrasonic frequency not lower than 28KHZ, ultrasonic power not lower than 200W), ultrasonic dispersion time not less than 30 minutes;

[0055] 4. Add an appropriate amount of boric acid (H 3 BO 3 ), continue ultrasound for no less than 30 minutes;

[0056] Five, the obtained graphene dispersion slurry is pr...

Embodiment 2

[0060] 1. Prepare graphene dispersion solution: Distilled water, isopropanol (IPA), N-methylpyrrolidone, according to the volume ratio of isopropanol:N-methylpyrrolidone is 1:2-1:10, isopropanol and N-Methylpyrrolidone: The volume ratio of distilled water is 1:1-3:1 to prepare a graphene dispersion solution, and adjust the pH value to 6 to 6 with one or more of ammonia water, acetic acid and tetramethylamine Between 11;

[0061] 2. Add an appropriate amount of graphene nano-chip powder to the prepared dispersion solvent to form a mixed slurry;

[0062] 3. Ultrasonic treatment of the mixed slurry (ultrasonic frequency not lower than 28KHZ, ultrasonic power not lower than 200W), ultrasonic dispersion time not less than 30 minutes;

[0063] 4. Add an appropriate amount of boric acid organic derivatives (BR) with a planar molecular structure into the mixed slurry 3 ), continue ultrasound for no less than 30 minutes;

[0064] Five, the obtained graphene dispersion slurry is prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com