Combined artificial wetland system and sewage treatment method thereof

A constructed wetland system and wetland technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. Area, strong reoxygenation ability, and the effect of alleviating the problem of easy blockage of subsurface flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

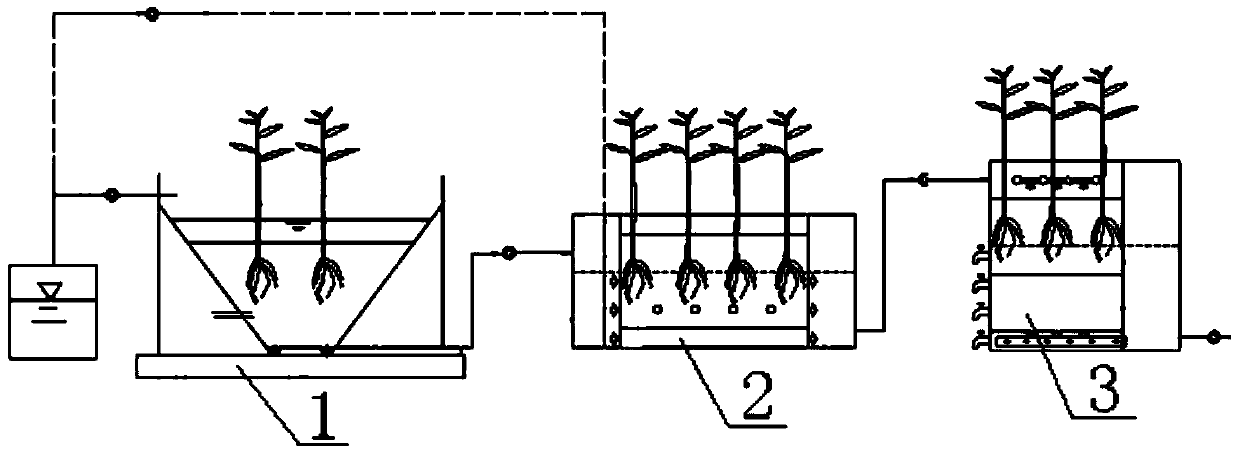

[0034] Such as figure 1 As shown, the device of the present invention mainly includes a three-stage subsurface flow wetland: a first-stage surface flow-subsurface flow composite flow wetland 1 , a second-stage horizontal subsurface flow wetland 2 and a third-stage vertical subsurface flow wetland 3 .

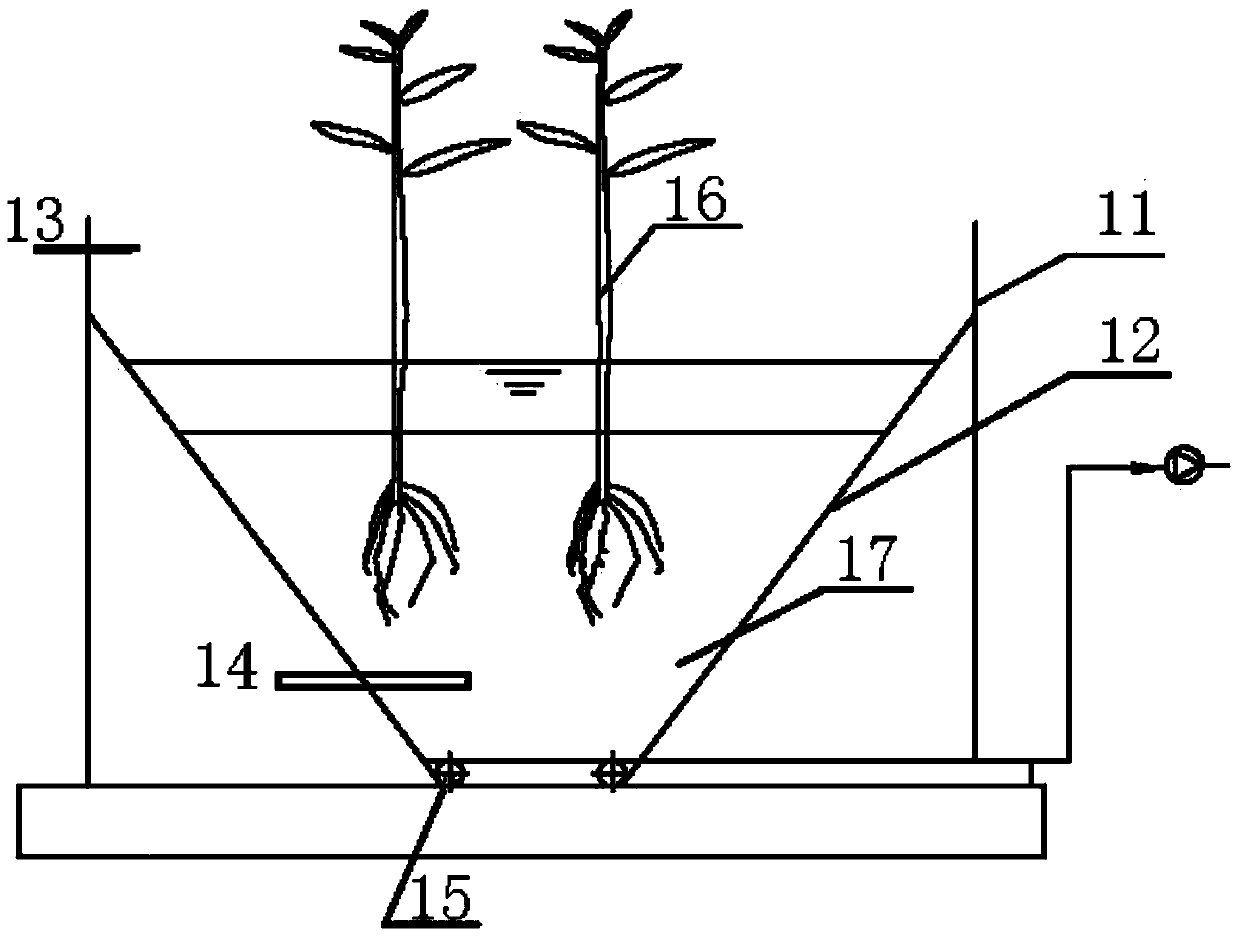

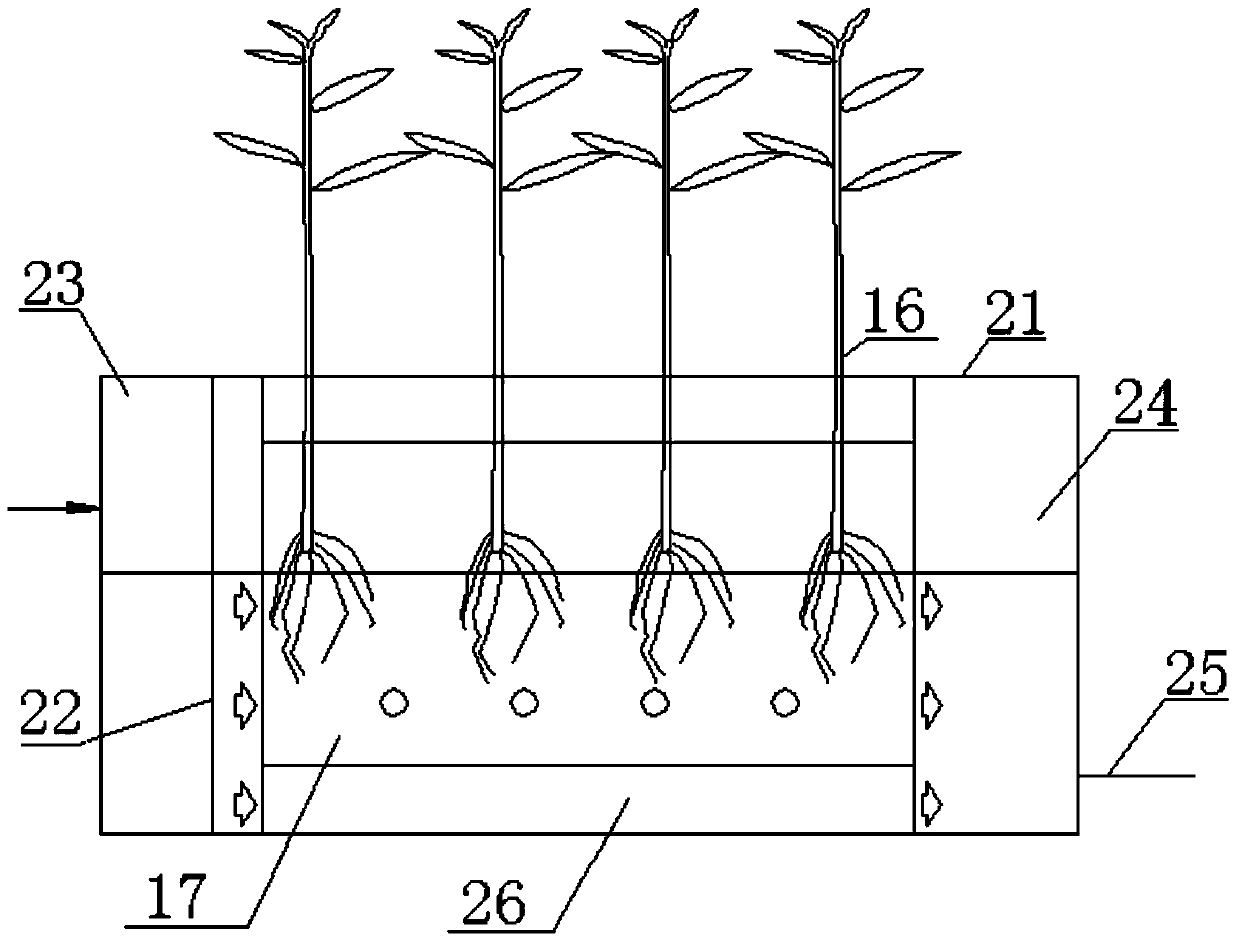

[0035] Such as figure 2 , the specific size of the first box 11 of the surface flow-subsurface flow composite flow wetland 1 is 70cm×70cm×100cm in length×width×height, and the first water inlet and distribution pipe 13 is an acrylic pipe, wherein the diameter of the main pipe is DN32, and the wetland is equipped with a trapezoidal shape Groove 12, this trapezoidal groove 12 is wide at the top and narrow at the bottom. The filler in the trapezoidal groove 12 is a calcium-aluminum mixed filler layer 17 with a thickness of 800 mm and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com