Vegetable seedling raising substrate and manufacturing method thereof

The technology of a vegetable seedling-raising substrate and its production method is applied in the field of vegetable seedling-raising substrate and its production, which can solve the problems of high cost of peat, difficulty in collecting, and immature production technology, etc., and achieve enrichment of trace elements, reduction of environmental pollution, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

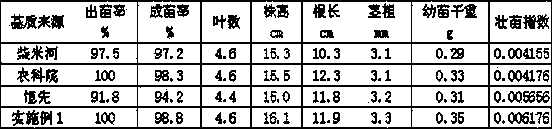

Examples

Embodiment 1

[0035] A vegetable seedling raising substrate, raw materials are organic waste such as vermiculite, perlite, biogas mud, carbonized rice husk, decomposed alcohol biogas residue fermentation material and coconut shell powder base material; wherein the coconut shell powder base material is domestic coconut The wet material formed by adding water to the bricks for expansion treatment has an expansion coefficient of 4, a water content of 40%, and a particle size of 1-6mm; biogas sludge is a material obtained by drying and crushing the sediment at the bottom of the biogas tank, with a particle size of 1-3mm; carbonization Rice husk is the ashes left after rice husk is burned and carbonized; alcohol biogas residue is the leftovers after cassava raw materials extract alcohol, and then the residue formed after anaerobic fermentation to generate biogas.

[0036] The matrix formula components are as follows by volume ratio: 30 parts of coconut shell powder base material, 15 parts of alco...

Embodiment 2

[0039] A vegetable seedling raising substrate, raw materials are organic waste such as vermiculite, perlite, biogas mud, carbonized rice husk, fermented alcohol biogas residue fermentation material and coconut shell powder base material; wherein the coconut shell powder base material is domestic coconut The material formed after adding water to the brick for expansion treatment, the expansion coefficient is 6, the water content is 50%, and the particle size is 1-6mm; The husk is the ashes left after the rice husk is burned and carbonized; the alcohol biogas residue is the leftovers after extracting alcohol from cassava raw materials, and then the residue formed after anaerobic fermentation to generate biogas.

[0040]The matrix formula components are as follows by volume ratio: 15 parts of coconut shell powder base material, 30 parts of alcohol biogas residue fermentation material, 15 parts of carbonized rice husk, 2 parts of biogas mud, 5 parts of perlite, and 24 parts of verm...

Embodiment 3

[0043] A kind of vegetable seedling raising substrate, raw material is the organic wastes such as vermiculite, perlite, biogas mud, carbonized rice husk and the alcohol biogas residue and coconut shell powder base material of fermented and decomposed treatment; However, the fermentation and composting time of alcohol biogas residue fermentation material is 30 days.

[0044] The coconut shell powder base material in the raw material is the material formed after the expansion treatment of imported coconut bricks with water, the expansion coefficient is 5.5, the water content is 45%, and the particle size is 1-6mm; the biogas sludge is the bottom sediment of the biogas tank after drying and crushing carbonized rice husk is the ashes left after rice husk is burned and carbonized; alcohol biogas residue is the leftovers after extracting alcohol from cassava raw materials, and then the residue formed after anaerobic fermentation to generate biogas.

[0045] The matrix formula compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com