Block polymer with pH/temperature/light triple responsiveness and preparation method thereof

A block polymer, responsive technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of cumbersome preparation methods of PAMAM, and achieve the effect of simplifying the synthesis process and steps, mild conditions and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A kind of preparation method of pH / temperature / fluorescent triple corresponding block polymer, comprises the following steps:

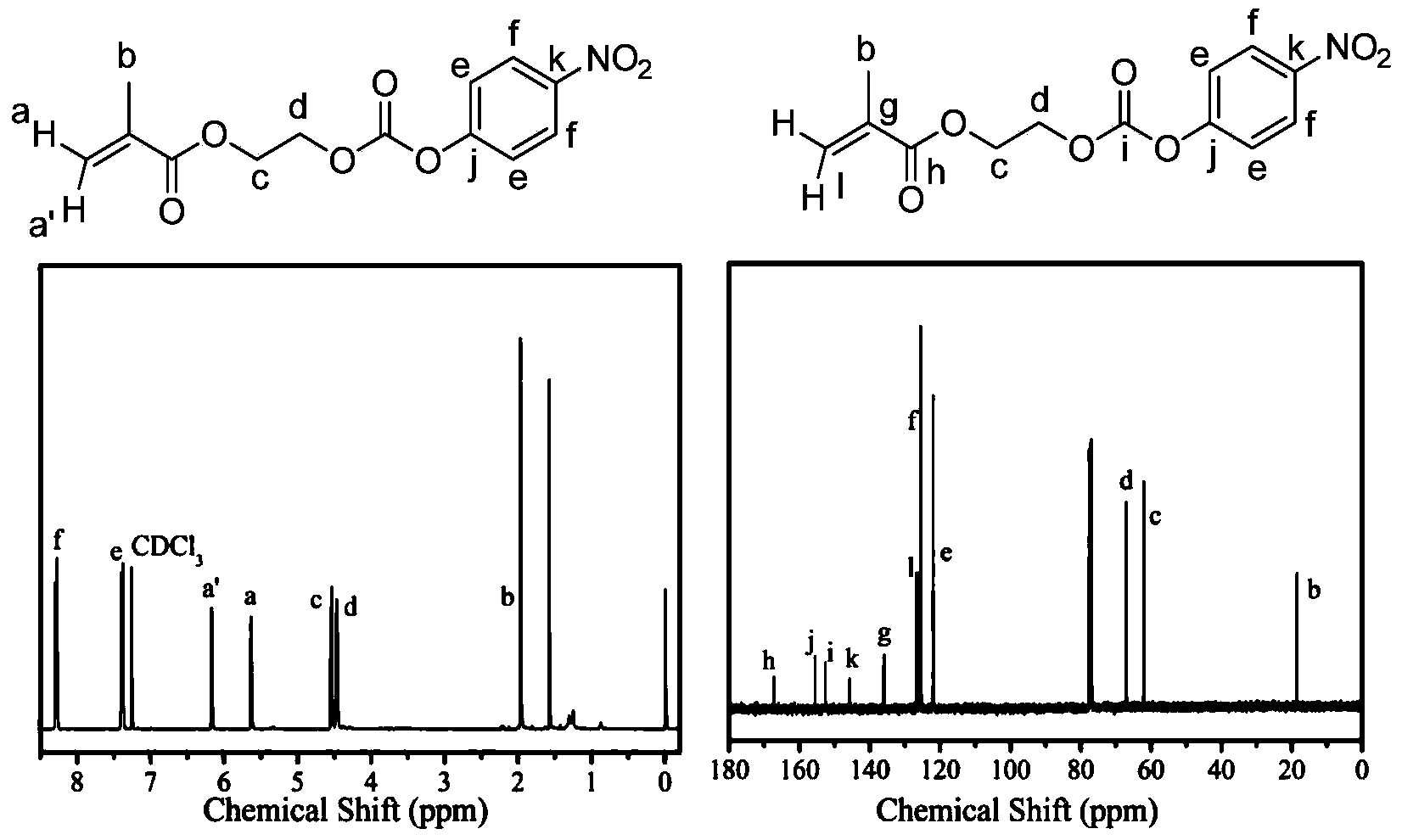

[0036] (1) Preparation of active monomer p-nitrophenoxycarboxyethyl methacrylate (NPCEMA):

[0037] Add 100mmol HEMA, 120mmol pyridine and 100mL dichloromethane into a 2-necked flask, and lower the temperature with an ice-water bath. Dissolve 120mmol of p-nitrophenyl chloroformate in 40mL of dichloromethane, and add it dropwise into the flask, and gradually rise to room temperature for reaction. Washed three times with dilute hydrochloric acid and saturated brine respectively, and anhydrous Na 2 SO 4 After drying, filtering, concentration, and passing through a basic alumina column, the obtained crude product was recrystallized in n-hexane, and then precipitated in cold methanol, and the precipitate was dried in a vacuum oven to obtain the white powder product NPCEMA.

[0038] (2) Preparation of poly-p-nitrophenoxycarbonoxyethyl...

Embodiment 2

[0044] Embodiment 2 A preparation method of a pH / temperature / fluorescent triple corresponding block polymer, comprising the following steps:

[0045] (1) Preparation of active monomer p-nitrophenoxycarboxyethyl methacrylate (NPCEMA):

[0046] Add 80mmol HEMA, 100mmol pyridine and 150mL N,N-dimethylformamide into a two-necked flask, and lower the temperature with an ice-water bath. Dissolve 100mmol of p-nitrophenyl chloroformate in 30mL of N,N-dimethylformamide, and slowly add it dropwise into the flask, and gradually rise to room temperature for reaction. Washed three times with dilute hydrochloric acid, saturated brine, anhydrous Na 2 SO 4 After drying, filtering, concentration, and passing through a basic alumina column, the obtained crude product was recrystallized in n-hexane, and then precipitated in cold methanol. After filtering, the product was dried in a vacuum oven to obtain a white powder product NPCEMA.

[0047] (2) Preparation of poly-p-nitrophenoxycarbonoxyeth...

Embodiment 3

[0053] Embodiment 3 A preparation method of a pH / temperature / fluorescent triple corresponding block polymer, comprising the following steps:

[0054] (1) Preparation of active monomer p-nitrophenoxycarboxyethyl methacrylate (NPCEMA):

[0055] Add 150mmol HEMA, 120mmol pyridine and 100mL dichloromethane into a two-necked flask, and lower the temperature with an ice-water bath. Dissolve 150mmol of p-nitrophenyl chloroformate in 50mL of dichloromethane, and slowly drop it into the flask, and gradually rise to room temperature for reaction. Washed three times with dilute hydrochloric acid, saturated brine, anhydrous Na 2 SO 4 After drying, filtering, concentration, and passing through a basic alumina column, the obtained crude product was recrystallized in n-hexane, and then precipitated in cold methanol. After filtering, the product was dried in a vacuum oven to obtain a white powder product NPCEMA.

[0056] (2) Preparation of poly-p-nitrophenoxycarbonoxyethyl methacrylate mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com