Light diffusion material

A light diffusion and light diffusion agent technology, which is applied in the field of light diffusion materials and modified polymer materials, can solve problems such as poor long-term thermal stability, and achieve good physical and mechanical properties, excellent aging resistance, and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

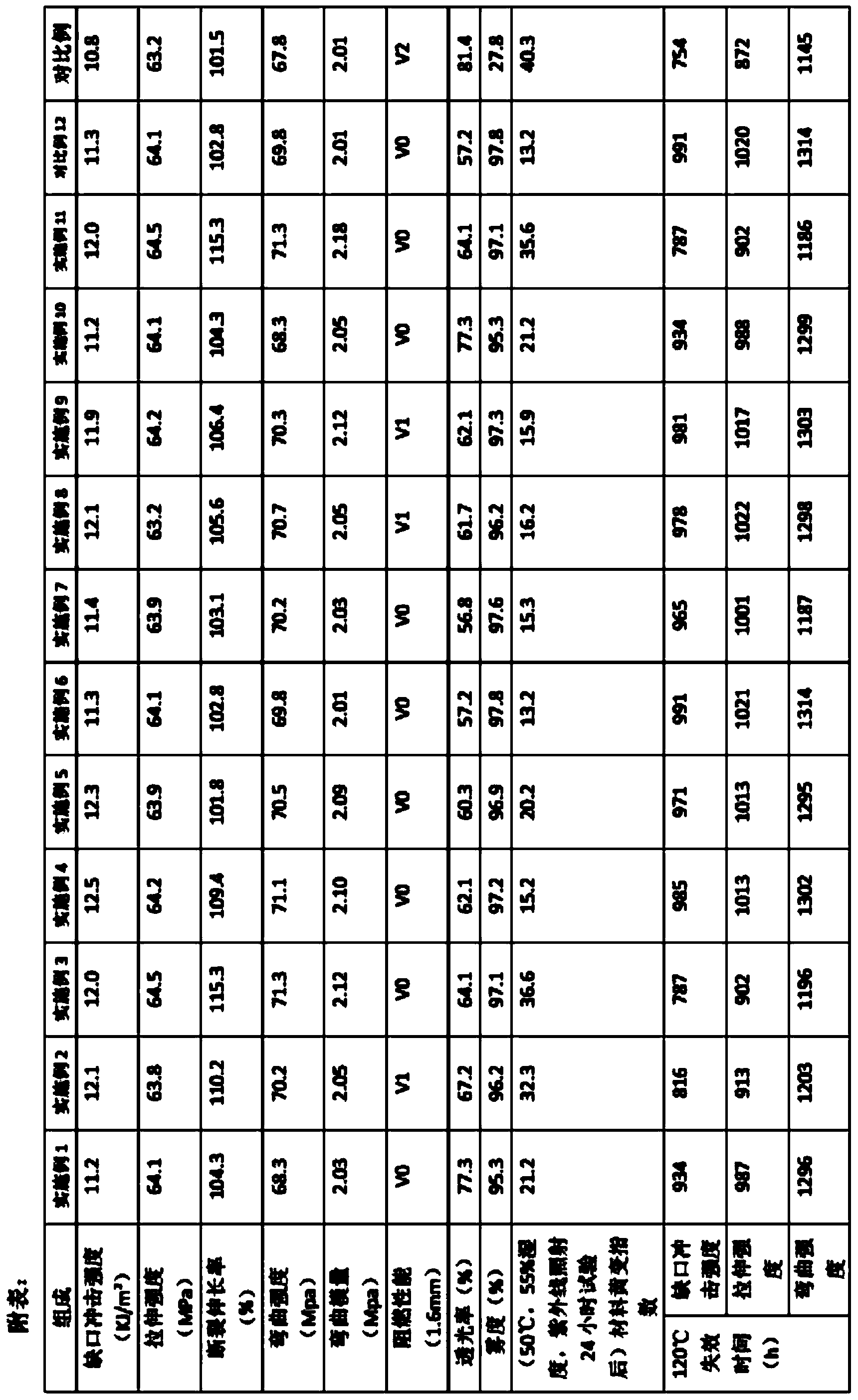

Examples

Embodiment 1

[0035] Polycarbonate resin (Taiwan Chimei 110U, melt index MFI is 10g / 10min) 100 parts, light diffusing agent (Japan Shin-Etsu KMP-590, Japan Nakabuchi MP-90 compounded at 3:1, particle size is 0.2-10μm) 2 parts, 1 part of light stabilizer (Cytec UV-5411), 2.1 parts of composite antioxidant (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tri [2.4-Di-tert-butylphenyl]phosphite, triethylene glycol bis[β-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate], 4,4 '-Thiobis(6-tert-butyl-3-methylphenol compounded according to 1.2:1.1:1:1), 5 parts of composite flame retardant (perfluorobutyl sulfonic acid, potassium benzocresol sulfonate , p-biphenylene tetraphenyl bisphosphate according to 3:1:1 compound), 0.2 parts of white oil, 0.1 parts of fluorescent whitening agent, 0.2 parts of toner, put them into a high-speed mixing container, and mix them at high and low speeds at room temperature. Mix for 3 to 5 minutes. After that, add the mixed materials in...

Embodiment 2

[0037] 100 parts of polycarbonate resin (Taiwan Chimei 110L, melt index MFI is 10g / 10min), 3 parts of light diffusing agent (Japan Shin-Etsu KMP-590, Japan Nakabuchi MP-90 according to 1:1 compounding, particle size is 0.2~ 10 μm), 0.2 parts of light stabilizer (Taiwan Yongguang Chemical EV72), 0.8 parts of composite antioxidant (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, bis( 2,4-di-tert-butylphenol) pentaerythritol diphosphite, triethylene glycol bis[β-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate], 4 , 4'-thiobis(6-tert-butyl-3-methylphenol compounded according to 1.2:1:1:1), 0.5 parts of composite flame retardant (perfluorobutyl sulfonic acid, benzocresol sulfonic acid Potassium acid potassium, p-biphenylene tetraphenyl bisphosphate according to 2.7:1:1 compound), 0.2 parts of white oil, 0.1 parts of fluorescent whitening agent, 0.2 parts of toner, processed according to the process given in Example 1 , extruded and granulated to o...

Embodiment 3

[0039] Polycarbonate resin (Bayer 2407, melt index MFI is 20g / 10min) 100 parts, light diffusing agent 4 parts (methyl methacrylate resin particles, particle size 0.2-10 μm), light stabilizer 2 parts (Cytec UV -5411), 0.3 parts of composite antioxidant (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tris[2.4-di-tert-butylphenyl] phosphorous acid Ester, triethylene glycol bis[β-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate], 2,6-di-tert-butyl-4-methylphenol 1:1:1:1 compound), 3.1 parts of composite flame retardant (perfluorobutane sulfonic acid, potassium benzocresol sulfonate, p-biphenylene tetraphenyl bisphosphate according to 2:1:1 Compound), 0.2 part of white oil, 0.1 part of fluorescent whitening agent, 0.2 part of toner, process according to the process given in Example 1, extrude and granulate to obtain the light-diffusing material composite material involved in the present invention, and the properties are listed in the appended surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com