High-pressure ultraviolet visible near-infrared spectroscopy device for online monitoring of supercritical system

A technology of near-infrared spectroscopy and near-infrared spectrometer, which is applied in the field of high-pressure in-situ ultraviolet-visible and near-infrared spectroscopy monitoring devices, can solve the problem of limiting the application of ultraviolet-visible spectroscopy technology in supercritical systems, and cannot meet the needs of on-line monitoring of supercritical systems, and the measurement results The problems of low reliability and reliability can be achieved to improve the mass transfer diffusion rate and test efficiency, improve the reproducibility and reliability, and achieve the effect of reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

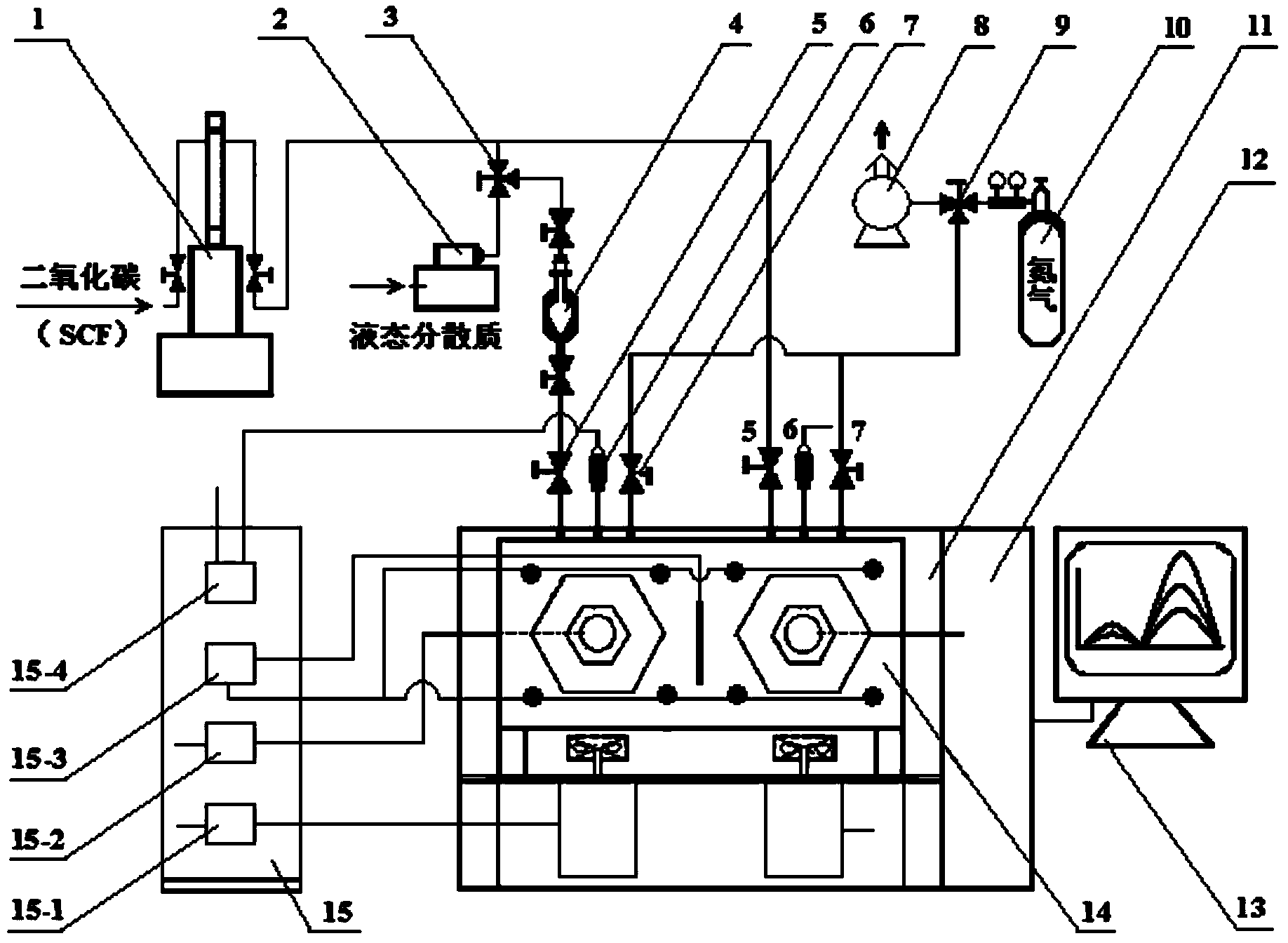

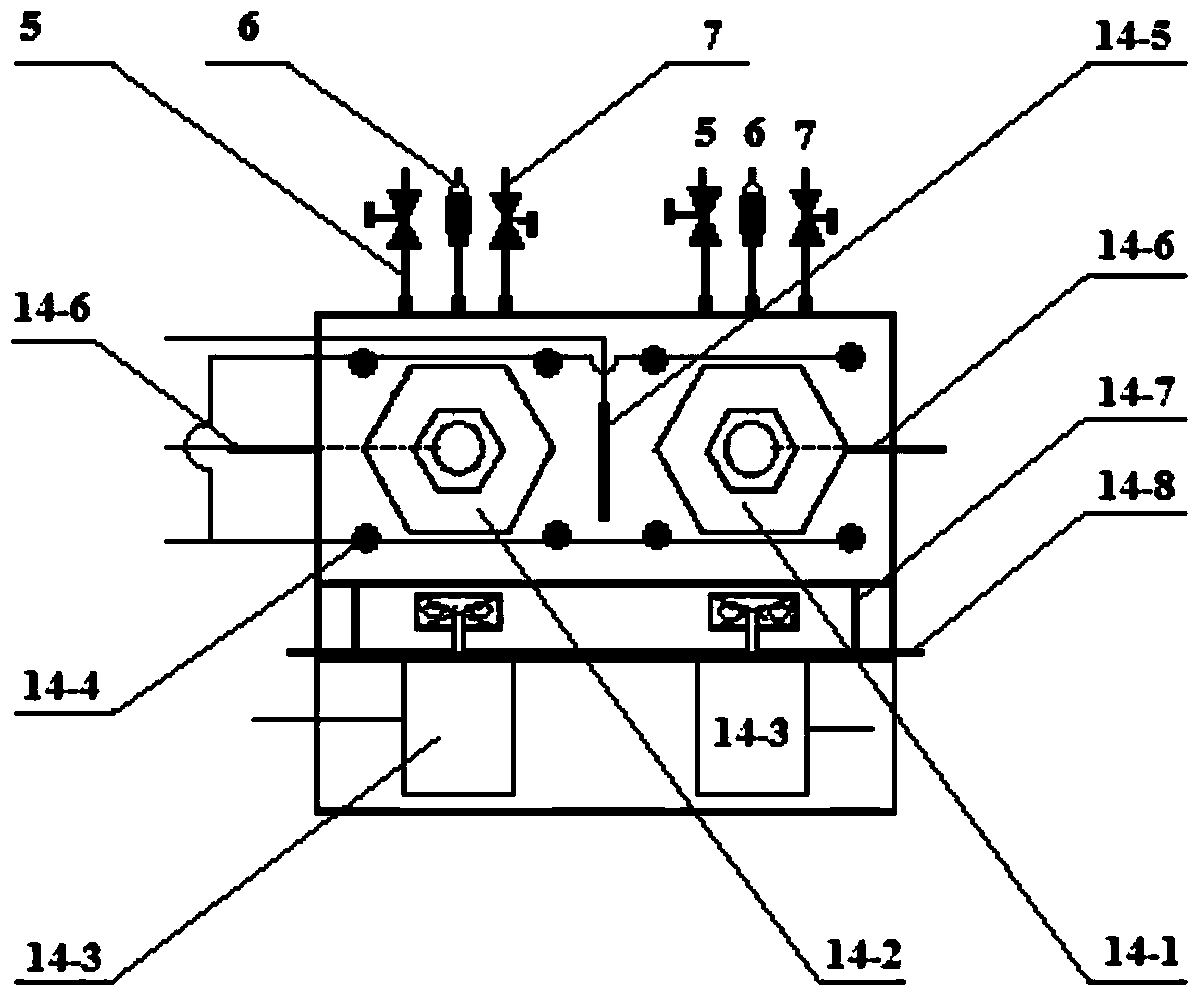

[0017] exist figure 1 Among them, the high-pressure in-situ ultraviolet-visible-near-infrared spectroscopy device for on-line monitoring of supercritical systems in this embodiment consists of a high-pressure injection pump 1, a sample metering pump 2, a gas-liquid three-way valve 3, a sample tube 4, a feed valve 5, a pressure Sensor 6, exhaust valve 7, vacuum pump 8, gas three-way valve 9, nitrogen cylinder 10, sample chamber 11, ultraviolet-visible-near-infrared spectrometer 12, computer 13, high-pressure reaction kettle 14, and controller 15 are connected to form.

[0018] In the present invention, a controller 15 is arranged on the left side, an ultraviolet-visible-near-infrared spectrometer 12 is arranged in the middle, a computer 13 is arranged on the right side, and a high-pressure reactor 14 is arranged in the sample chamber 11 of the ultraviolet-visible-near-infrared spectrometer 12, and a high-pressure reactor 14 Link to each other with controller 15 by wire, control...

Embodiment 2

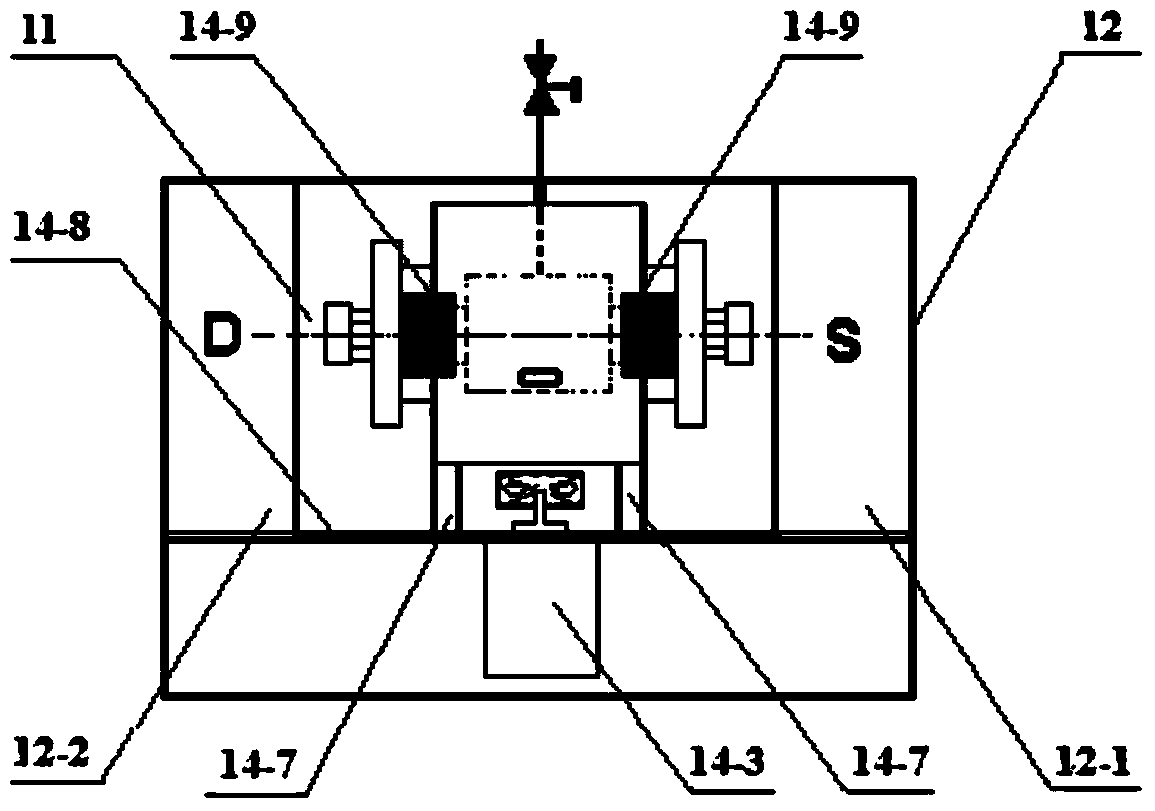

[0026] The high-voltage visible window 14-9 in this embodiment is a quartz visible window, and the quartz visible window is a cylinder. 12 is an ultraviolet-visible-near-infrared spectrometer. The optical axes of the analysis light path and the reference light path between the light source 12-1 and the detector 12-2 of the ultraviolet-visible-near-infrared spectrometer 12 are respectively perpendicular to the bottom surface of the corresponding high-voltage visible window cylinder. The basic performance parameters of the high-pressure ultraviolet-visible-near-infrared spectroscopy device for on-line monitoring of the supercritical system in this embodiment are: the working pressure is 0.1-20MPa, the working temperature is 20-200oC, and the wavelength range of spectral scanning is 190-2500nm. The other components and the connection relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0028] The high-voltage visible window 14-9 in this embodiment is a sapphire visible window, and the sapphire visible window is a cylinder. 12 is an ultraviolet-visible spectrometer. The optical axes of the analysis optical path and the reference optical path between the light source 12-1 and the detector 12-2 of the ultraviolet-visible spectrometer 12 are respectively perpendicular to the bottom surface of the corresponding high-voltage visible window cylinder. The basic performance parameters of the high-pressure ultraviolet-visible spectroscopy device for on-line monitoring of the supercritical system in this embodiment are: the working pressure is 0.1-40MPa, the working temperature is 20-200oC, and the wavelength range of spectral scanning is 200-900nm. The other components and the connection relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com