Sequencing batch electrode polarity reversal microbial fuel cell and use thereof

A fuel cell and sequencing batch technology, applied in the field of environmental engineering, can solve the problem of lack of coupling, and achieve the effects of improving efficiency, reducing costs, and operating flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

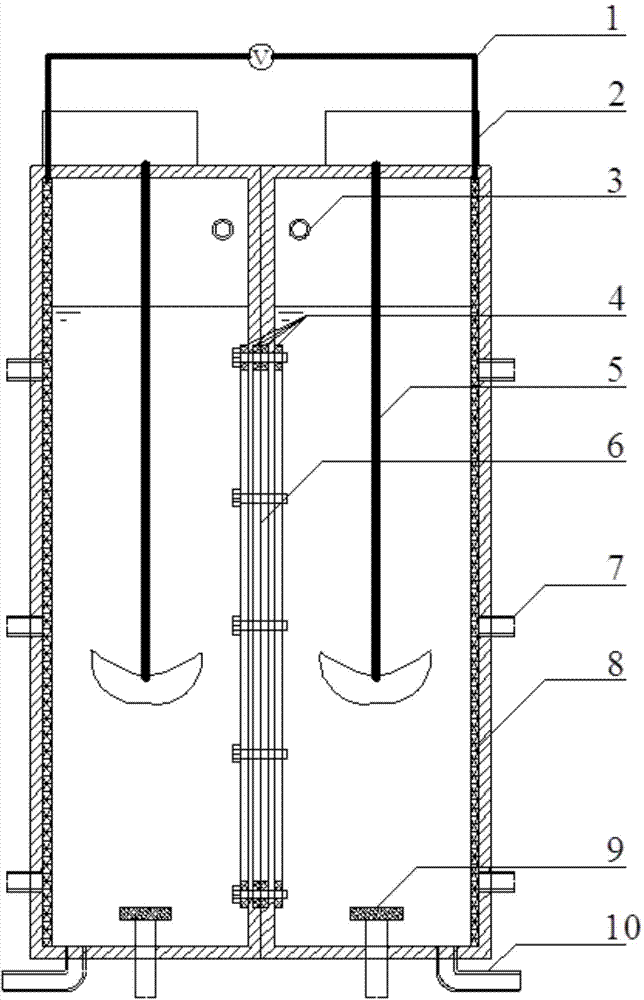

[0018] A sequencing batch type electrode reversal microbial fuel cell, the structure of the battery: the battery includes two symmetrical SBR reactors, and there is a gasket in the middle of the two symmetrical SBR reactors to fix the cation exchange membrane and prevent water leakage; Each SBR reactor acts as a half-cell and goes through anaerobic, aerobic and anoxic stages. The motor is installed on the top of the reactor. The anaerobic stage and the anoxic stage are driven by the motor to stir the stirring rod; the aerobic stage is passed through the bottom of the SBR reactor. The aeration head is used for aeration, and the exhaust is carried out through the vent hole located above the liquid level of the SBR reactor; the sequence batch difference of the two symmetrical SBR reactors makes there is a potential difference between the two symmetrical SBR reactors, so as to The carbon felt is used as an electrode to connect to the external circuit to generate current; the sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com