Iron nitride/nitrogen-doped graphene aerogel as well as preparation method and application thereof

A technology of nitrogen-doped graphene and graphene airgel, which is applied in chemical instruments and methods, chemical/physical processes, electrical components, etc., can solve the problem of low catalytic activity, achieve excellent performance, low cost, and superior stability and the effect of methanol oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of graphite oxide:

[0041] In the present embodiment, graphite oxide is prepared by the following method: 1g graphite powder, 0.5g NaNO 3 And 23mL of concentrated sulfuric acid were added to a 250mL round bottom flask and stirred at room temperature for 24h.

[0042] Next, move the round-bottomed flask into an ice-water bath, and slowly add 3g of KMnO4 under vigorous stirring; deionized water, and then stirred for 15 min; then added 140 mL of water for dilution, and finally added 10 mL of 30% H 2 o 2 Stir for 10 min to end the reaction, and obtain a bright yellow suspension containing graphite oxide.

[0043] The above bright yellow suspension was centrifuged, the precipitate was washed twice with 10% HCl solution by volume, once with deionized water, centrifuged again, the precipitate was collected and dried in an oven at 70°C. The graphite oxide product was collected as a feedstock for subsequent steps.

[0044] 2. Preparation of iron nitride / nitr...

Embodiment 2

[0053] The graphite oxide prepared in Example 1 was used to prepare the iron nitride / nitrogen-doped graphene airgel, and the following examples were the same.

[0054] Disperse 24mg of graphite oxide and 24mg of ferrous phthalocyanine in 4mL of deionized water, and use ultrasonic dispersion to make it into a stable suspension to obtain a mixed solution;

[0055] Then transfer the mixed solution to a 20mL reaction kettle, add 12mL deionized water to make the graphite oxide concentration 1.5mg / mL, the mixed solution accounts for 80% of the reaction kettle volume, and carry out hydrothermal reaction at 200°C for 12h. Obtain hydrothermal reaction product;

[0056] The above hydrothermal reaction product was dried by freeze-drying method, and annealed at 700° C. for 3 hours in an ammonia atmosphere to obtain iron nitride / nitrogen-doped graphene airgel.

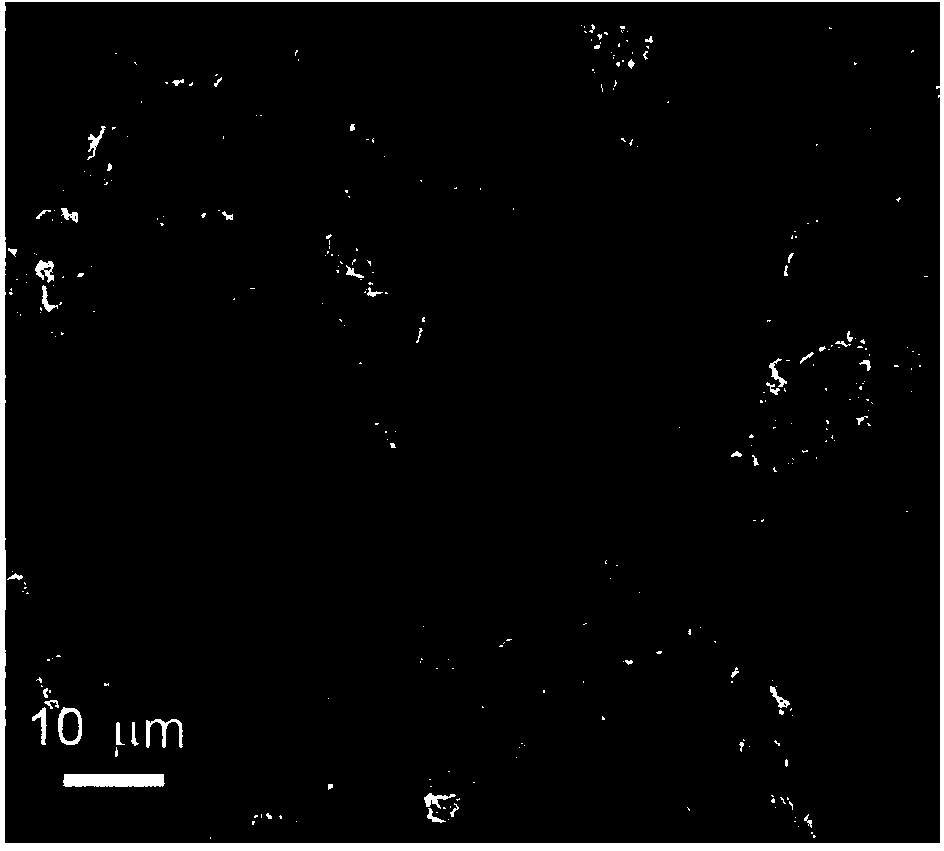

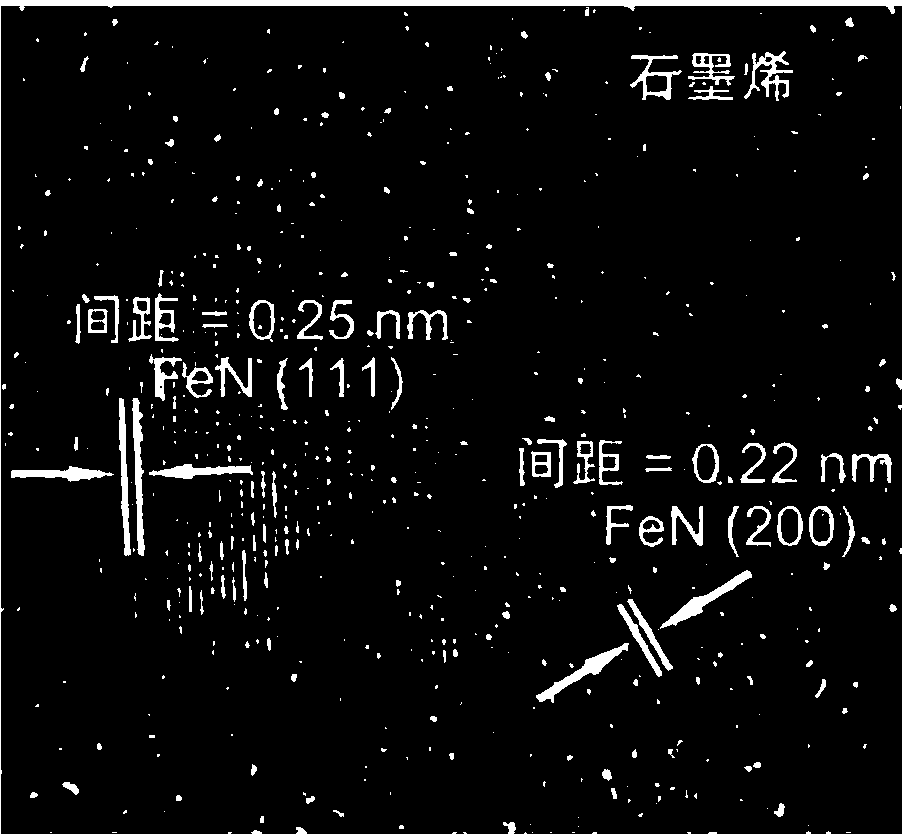

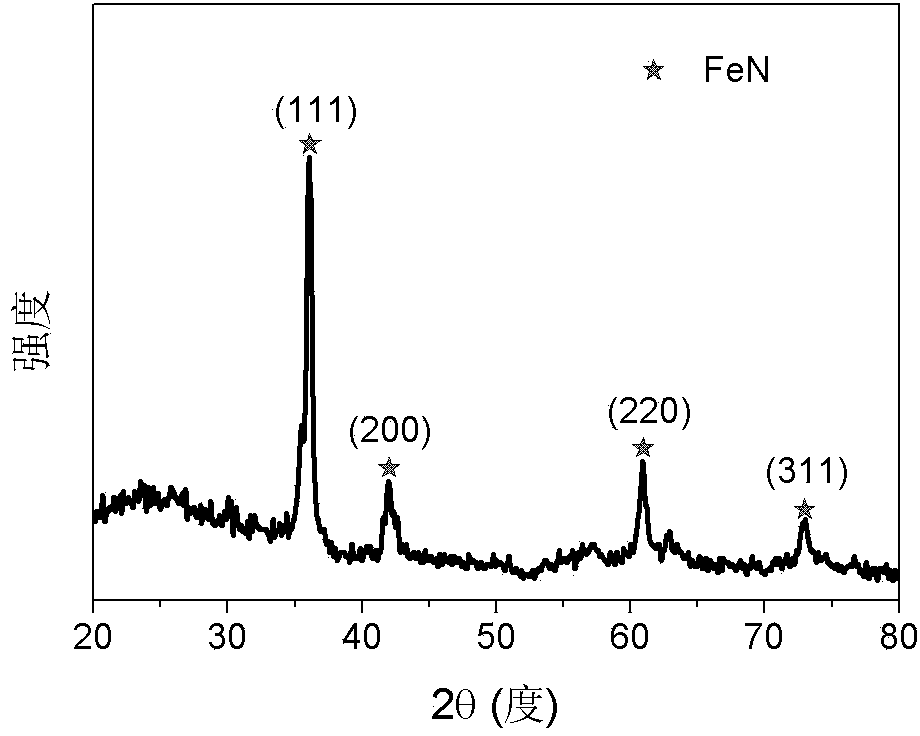

[0057] The obtained iron nitride / nitrogen-doped graphene airgel was characterized by TEM and SEM, and the results were the same ...

Embodiment 3

[0059] Disperse 24mg of graphite oxide and 24mg of ferrous phthalocyanine in 4mL of deionized water, and use ultrasonic dispersion to make it into a stable suspension to obtain a mixed solution;

[0060] Then transfer the mixed solution to a 20mL reaction kettle, add 12mL deionized water to make the graphite oxide concentration 1.5mg / mL, the mixed solution accounts for 80% of the reaction kettle volume, and carry out hydrothermal reaction at 180°C for 12h. Obtain hydrothermal reaction product;

[0061] The above hydrothermal reaction product was dried by freeze-drying method, and annealed at 750° C. for 3 hours in an ammonia atmosphere to obtain iron nitride / nitrogen-doped graphene airgel.

[0062] The obtained iron nitride / nitrogen-doped graphene airgel was characterized by TEM and SEM, and the results were the same as in Example 1. X-ray photoelectron spectroscopy analysis shows that the iron content is 2.01%, and the nitrogen content is 6.87%. This material is used as a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com