Insulating polymer based electromagnetic shielding material and preparation method thereof

A technology for electromagnetic shielding materials and electromagnetic shielding layers, which is applied in the field of preparing insulating polymer-based electromagnetic shielding materials with a multi-layer structure, and can solve problems such as complexity, complicated process, and programmed temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

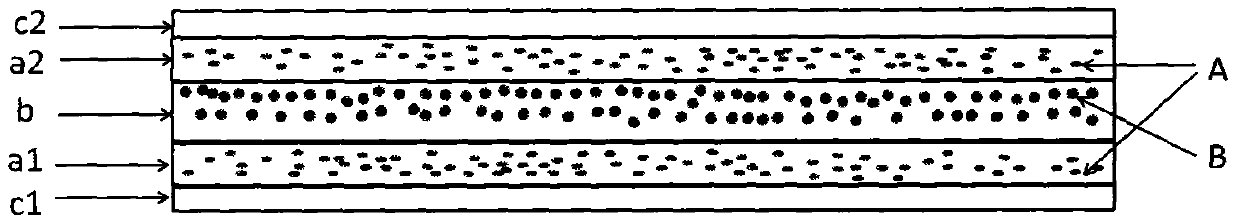

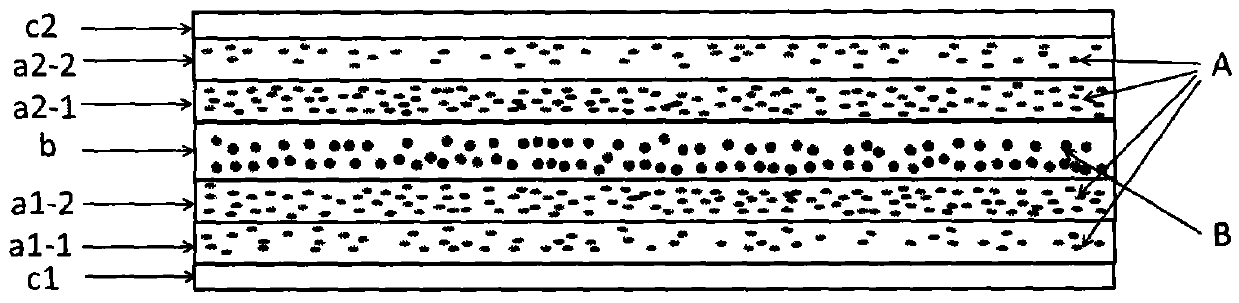

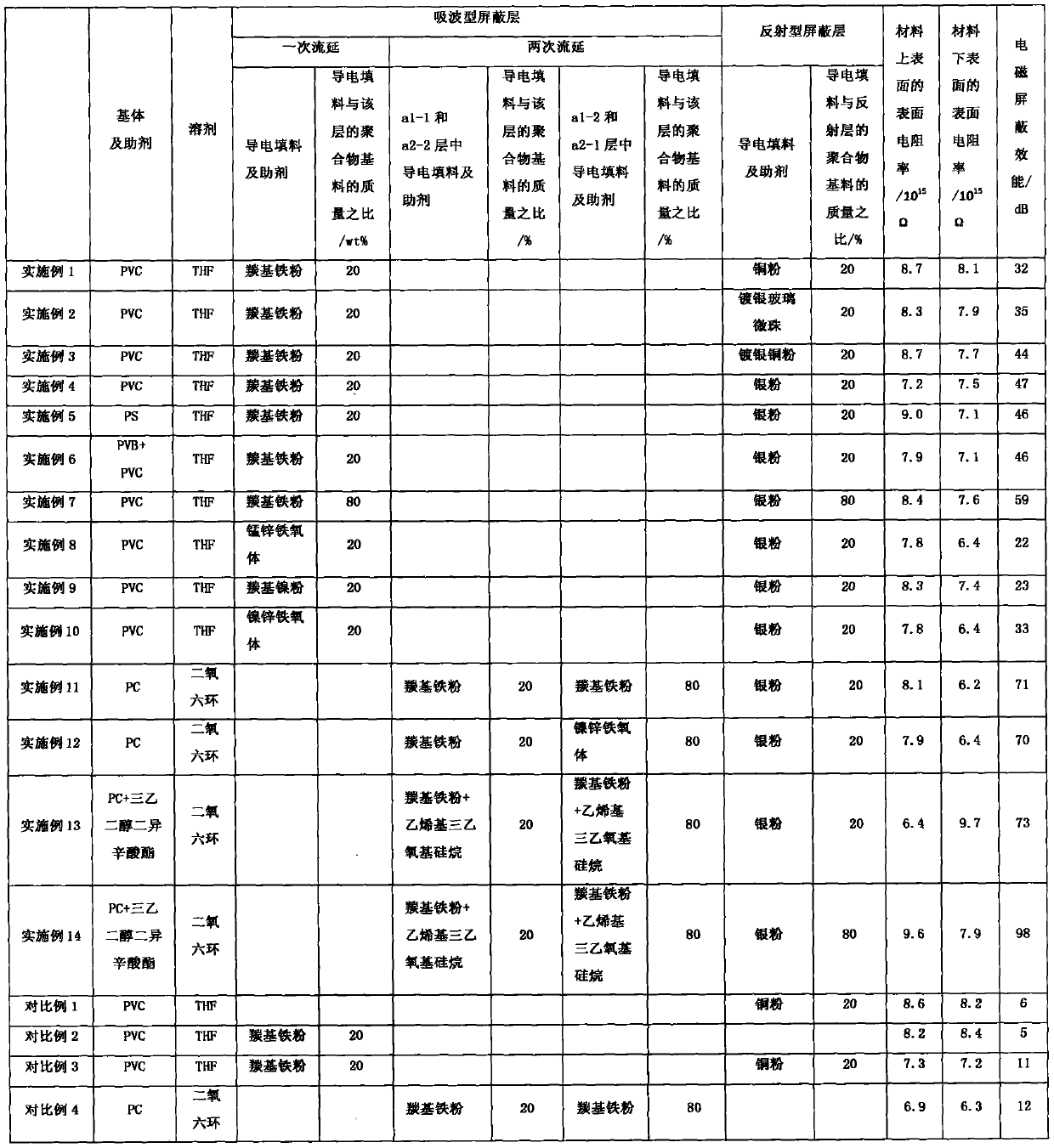

Embodiment 1

[0038] To prepare the insulating layer c polymer solution, the specific process is as follows: Put 6g PVC and 100ml THF into a three-necked flask with a stirring device, and stir at room temperature at a stirring speed of 300 rpm until the PVC is completely dissolved. , Call this solution Lc-1; prepare the polymer / conductive filler solution used in the electromagnetic shielding layer a. The specific process is as follows: Fill a three-necked flask with a stirring device into 6g PVC and 100ml THF, and stir Under the condition of a speed of 300 revolutions per minute, stir at room temperature until the PVC is completely dissolved, then add 1.2g (20wt%) of carbonyl iron powder and stir for 300 minutes. This solution is called La-1; a reflective electromagnetic shielding layer is prepared b. The specific process of the polymer / conductive filler solution used is as follows: Fill a three-necked flask with a stirring device into 6g PVC and 100ml THF, and stir at room temperature under ...

Embodiment 2

[0041] The method is the same as in Example 1, replacing the copper powder with silver-plated glass beads. Detect the upper surface of the insulating electromagnetic shielding material (such as figure 1 C2) the surface resistivity is ρ S1 =8.3×10 15 Ω, the bottom surface (such as figure 1 C1) surface resistivity ρ S2 =7.9×10 15 Ω, test its electromagnetic shielding effectiveness under the electromagnetic wave frequency of 0.3MHz~1.5GHz to be about 35dB. Table 1 lists the surface resistivity and electromagnetic shielding effectiveness of the upper and lower surfaces of the material.

Embodiment 3

[0043] The method is the same as in Example 1, replacing the copper powder with silver-plated copper powder. Detect the upper surface of the insulating electromagnetic shielding material (such as figure 1 C2) the surface resistivity is ρ S1 =8.7×10 15 Ω, the bottom surface (such as figure 1 C1) surface resistivity ρ S2 =7.7×10 15 Ω, testing its electromagnetic shielding effectiveness at the electromagnetic wave frequency of 0.3MHz ~ 1.5GHz is about 44dB. Table 1 lists the surface resistivity and electromagnetic shielding effectiveness of the upper and lower surfaces of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

| Single layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com