Metal ceramic composite material used at temperature less than 1,200 DEG C

A composite material and cermet technology, applied in the field of composite materials, can solve problems such as hindering wide application, poor reliability, and high brittleness of ceramics, and achieve the effects of small residual stress, buffer load and deflection crack, and small fiber damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

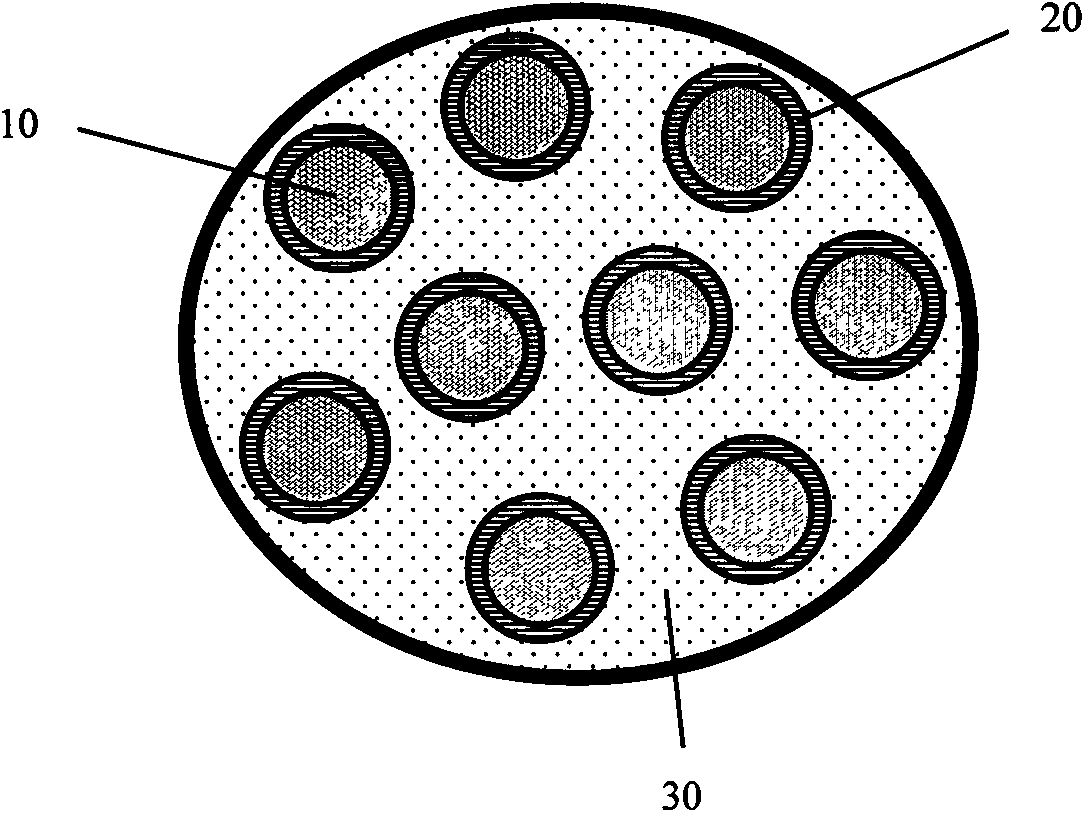

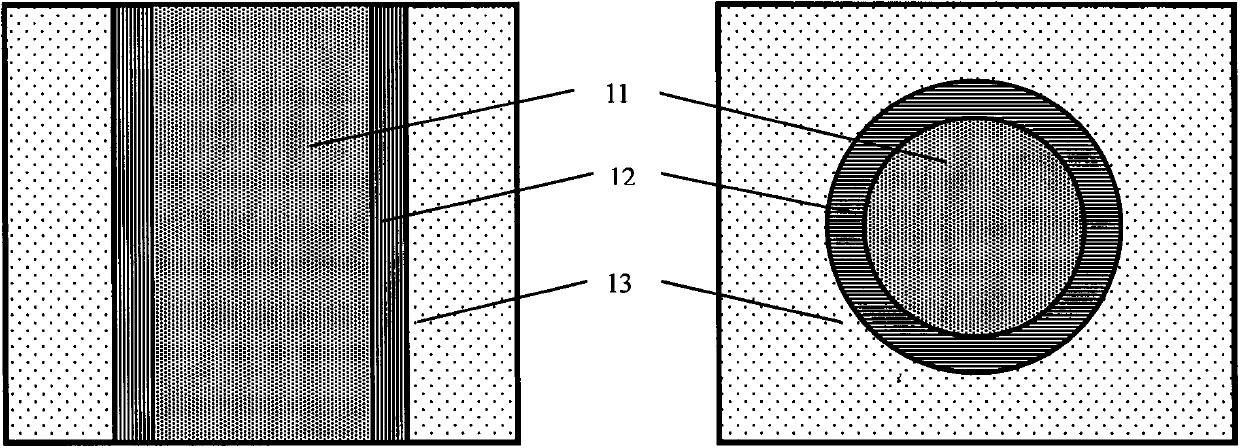

[0018] Carbon fibers and nickel-chromium-nickel-silicon alloy wires are plied and twisted, and woven into a three-dimensional preform through three-dimensional weaving technology, and the fiber content is controlled to 60%; the carbon interface layer is prepared by the CVI method, and the thickness of the interface layer is controlled by relevant process parameters. 0.3 μm; and then in the same CVI equipment, trichloromethylsilane is used as a precursor to decompose SiC under appropriate conditions to fill the gaps of the preform densely to form a metal-ceramic composite material.

Embodiment 2

[0020] Combine carbon fibers and nickel-chromium-nickel-silicon alloy wires into bundles, first weave them into two-dimensional cloth, and then wind the cloth into tubes or other three-dimensional shapes, and control the fiber content to 70%; prepare the BN interface layer by the CVI method, and pass the relevant process parameters The thickness of the interfacial layer is controlled to 0.5 μm; then in the same CVI equipment, trichloromethylsilane is used as the precursor, and SiC is decomposed under appropriate conditions to fill the gaps of the preform densely to form a metal-ceramic composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com