Humic acid organic-inorganic medicine fertilizer composition containing bacillus subtilis and/or bacillus megatherium utilizing waste of sugar refinery and alcohol plant

A technology of Bacillus subtilis, Bacillus megaterium, applied in the direction of fertilizer mixture, application, fertilization method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

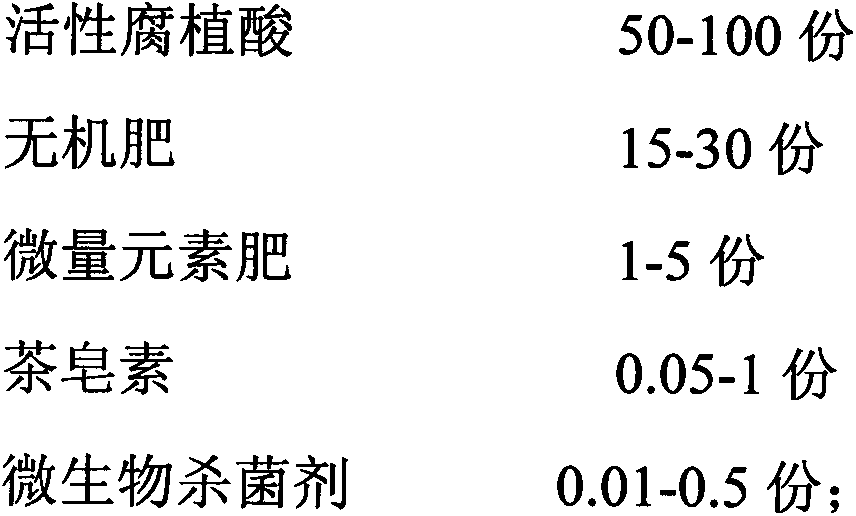

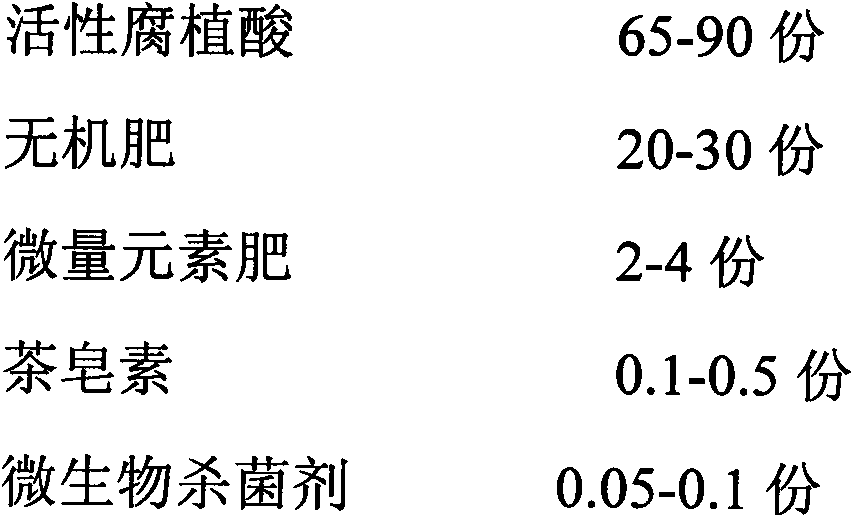

Method used

Image

Examples

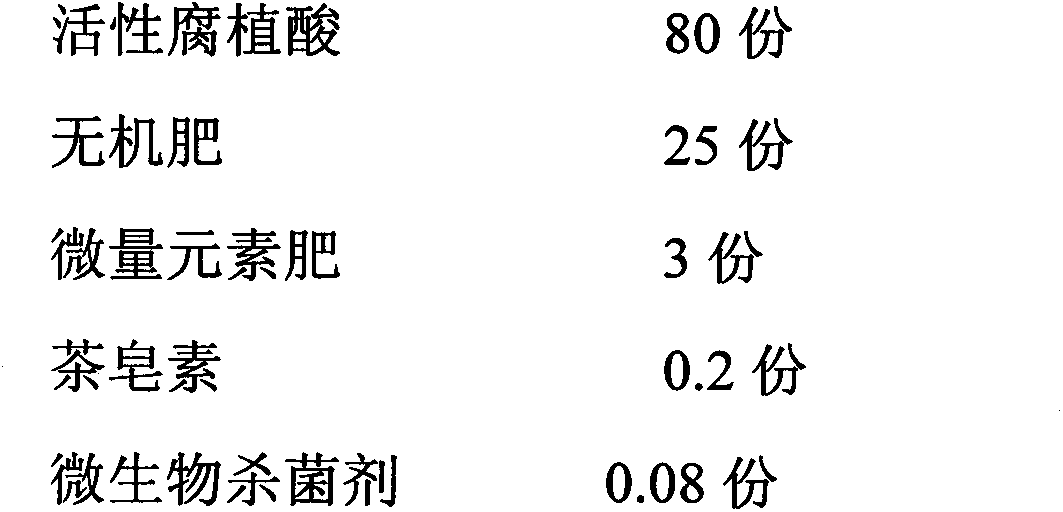

Embodiment 1

[0099] Take 950kg of alcohol waste liquid from the sugar cane sugar factory, let it stand for clarification, and obtain the supernatant, then heat the supernatant to 75°C for evaporation and concentration to obtain 190kg of the concentrate, add nitric acid until the pH of the concentrate is 3. Stand at room temperature for 18 hours for activation, then add ammonia water to adjust the pH to 7 to obtain active humic acid liquid, dry the active humic acid liquid, pulverize, and sieve to obtain active humic acid, about 80kg for later use.

[0100] Take potassium nitrate 12.5kg and potassium chloride 12.5kg respectively, manganese fertilizer 2kg and zinc fertilizer 1kg, tea saponin 200g, live spore number is 7 * 10 live spores / gram Bacillus subtilis mother powder 60g and live spore number are 3×10 10 Live spores / gram of Bacillus megaterium 20g are used for later use.

[0101] The above-mentioned ingredients were mixed uniformly to obtain a mixture; and 4kg of 10% starch aqueous so...

Embodiment 2

[0104] Get 1200kg of beet sugar factory alcohol waste liquid, let it stand for clarification, and obtain a supernatant, then heat the supernatant to 85°C for evaporation and concentration to obtain 240kg of a concentrate, add nitric acid until the pH of the concentrate is 2. Leave to activate at room temperature for 15 hours, then add ammonia water to adjust the pH to 7 to obtain active humic acid liquid, dry the active humic acid liquid, pulverize, and sieve to obtain active humic acid, about 100kg for later use.

[0105] Weigh 20kg of potassium nitrate, 5kg of iron fertilizer, 1000g of tea saponin, and the number of live spores is 5×10 10 Live spores / gram of Bacillus subtilis parent powder 200g for later use.

[0106] The above-mentioned ingredients were mixed uniformly to obtain a mixture; and 7kg of 15% starch aqueous solution was added thereto for granulation.

[0107] The obtained granules are dried and sieved to obtain the humic acid type organic-inorganic medicinal fe...

Embodiment 3

[0109] Take 950kg of alcohol waste liquid from the sugar cane sugar factory, let it stand for clarification, and obtain the supernatant, then heat the supernatant to 75°C for evaporation and concentration to obtain 190kg of the concentrate, add nitric acid until the pH of the concentrate is 3. Stand at room temperature for 18 hours for activation, then add ammonia water to adjust the pH to 7 to obtain active humic acid liquid, dry the active humic acid liquid, pulverize, and sieve to obtain active humic acid, about 80kg for later use.

[0110] Weigh respectively 12.5kg of potassium nitrate and 12.5kg of potassium chloride, 2kg of manganese fertilizer and 1kg of zinc fertilizer, 200g of tea saponin, and the number of live spores is 7×10 9 Live spores / gram of Bacillus subtilis mother powder 60g and the number of live spores is 3×10 10 Live spores / gram of Bacillus megaterium 20g, 10% spinosad wettable powder 50g (equivalent to 5g of spinosad active ingredient) for later use.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com