Energy-saving optimization technology of deep hydrolysis system for improving urea production capacity

A technology of production capacity and urea, applied in the chemical industry, products, organic chemistry, etc., to reduce production energy consumption, increase urea output, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

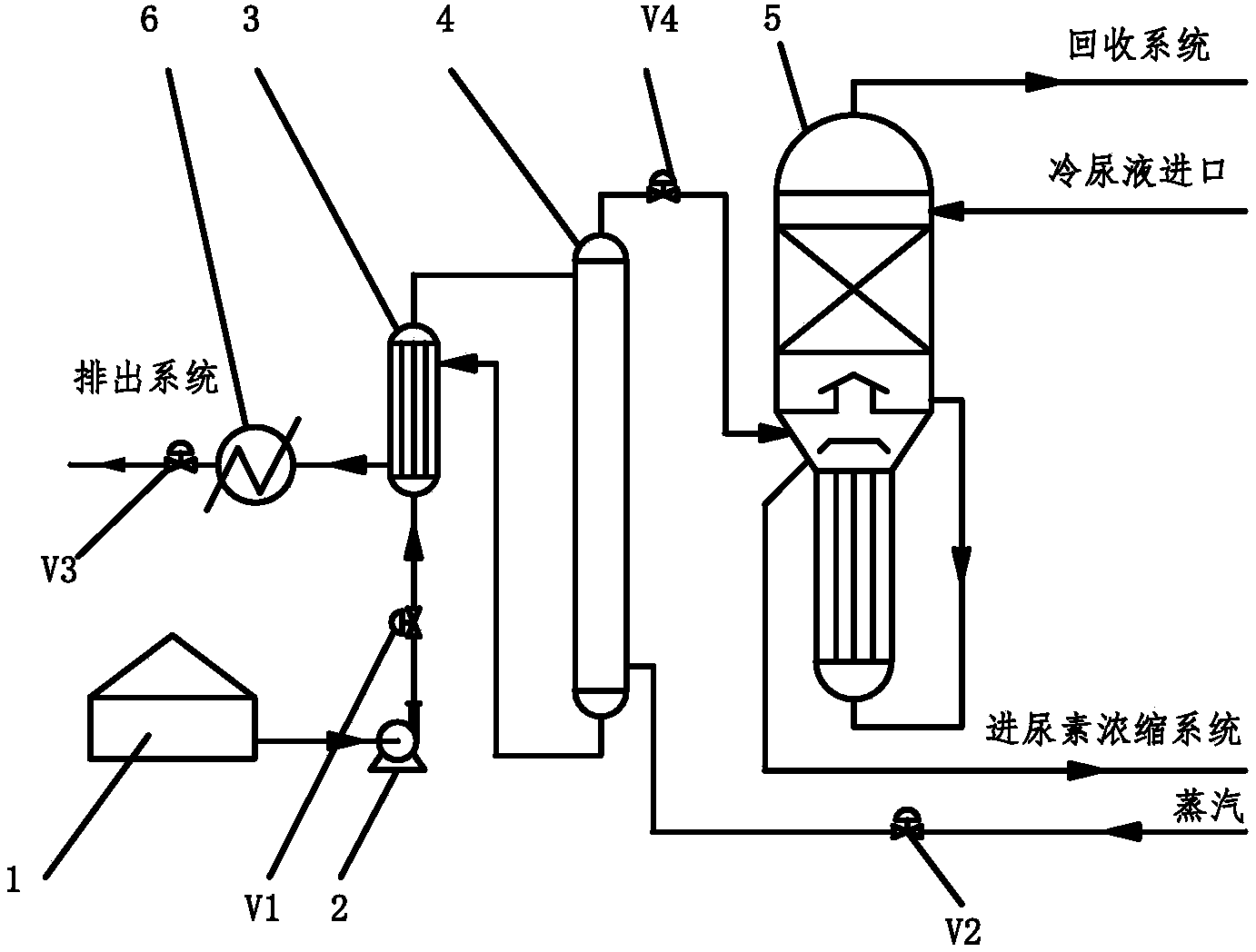

[0021] 1. The process condensate containing ammonia, carbon dioxide, urea and water from the process condensate tank (1) is sent to the high-efficiency heat exchanger (3) through the stripping-hydrolysis pump (2), and the (4) The liquid at the bottom (190-220°C) undergoes heat exchange, and after being preheated to 180-200°C, it enters the stripping-hydrolysis tower (4). The urea in the process condensate is completely hydrolyzed under high temperature and sufficient residence time in the stripping-hydrolysis tower (4), and finally the hydrolyzed waste liquid is discharged from the bottom of the tower through the high-efficiency heat exchanger (3) and the waste liquid cooler (6). To the outside world, the content of urea and ammonia is not more than 5ppm, which can be directly used as feed water for low-pressure boilers or sent to the feed water pretreatment system of high-pressure boilers to achieve high-level recycling of water. The free ammonia and carbon dioxide in the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com