Preparation method for super early-strength type poly carboxylic acid admixture

A super-early-strength type and admixture technology, applied in the field of concrete admixtures, can solve problems such as poor cement adaptability, achieve high cement adaptability, high water reducing rate, and improve the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

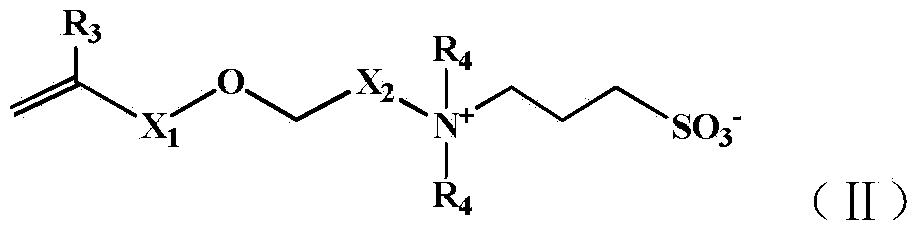

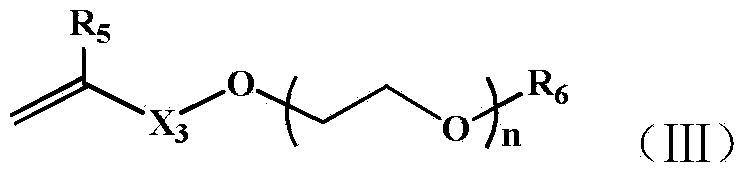

Method used

Image

Examples

Embodiment 1

[0047] Add 300g of distilled water and 143.6g of polyether macromonomer c-1 into a 1L glass round-bottom flask equipped with a thermometer, stirrer, dropping funnel and nitrogen gas conduit, stir and raise the temperature to dissolve, and purge the round-bottom flask with nitrogen to remove oxygen in the system. Under the protection of nitrogen, the temperature was raised to 90°C, and then 3.9g of monomer a-1, 32.4g of monomer b-1, 1.78g of 3-mercaptopropionic acid and 150g of water were mixed and stirred to form a uniform monomer aqueous solution, which was uniformly Added dropwise to a round bottom flask for 5h. At the same time, an aqueous initiator solution prepared by 260 g of distilled water and 3.56 g of potassium persulfate was added dropwise at a constant speed for 5.5 hours. After adding the whole solution dropwise, keep the constant temperature for 6 hours, then lower the temperature to about 40°C, add sodium hydroxide to neutralize to pH=7.5, and obtain the super ...

Embodiment 2

[0049] Add 260g of distilled water and 261.2g of polyether macromonomer c-2 into a 1L glass round-bottom flask equipped with a thermometer, stirrer, dropping funnel and nitrogen gas conduit, stir and raise the temperature to dissolve, and purge the round-bottom flask with nitrogen to remove oxygen in the system. Under the protection of nitrogen, the temperature was raised to 80°C, and then 20.2g of monomer a-2, 10.6g of monomer a-4, 16.1g of monomer b-2, 0.62g of mercaptoacetic acid and 120g of water were mixed and stirred to form a uniform monomer The aqueous solution was added dropwise to the round bottom flask at a constant speed for 4 hours. At the same time, an aqueous initiator solution prepared by 180 g of distilled water and 1.54 g of azobisisobutylamidine hydrochloride was added dropwise at a constant speed for 4.5 hours. After the addition of the whole solution, continue to keep the constant temperature for 5 hours, then lower the temperature to about 40°C, add trie...

Embodiment 3

[0051] In a 1L glass round-bottomed flask equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen conduit, add 360g of distilled water, 264.2g of polyether macromonomer c-3 and 1.41g of 30% hydrogen peroxide, stir and heat up to dissolve, The round bottom flask was purged with nitrogen to remove the oxygen in the system. Under nitrogen protection, heat up to 35°C, then mix and stir 28g of monomer a-3, 22.3g of monomer b-1, 25.4g of monomer b-3, 0.18g of mercaptoethanol, 0.23g of L-ascorbic acid and 190g of water A homogeneous monomer aqueous solution was prepared, which was added dropwise to a round bottom flask at a constant speed for 2 hours. After the dropwise addition of the monomer solution, continue to keep the constant temperature for 4 hours, then lower the temperature to about 30°C, add potassium hydroxide to neutralize to about pH=7.5, and obtain the super early strength polycarboxylic acid admixture PC-3 with a solid content of 39.3%. , GPC test th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com