Synthesis method for block-type sulfonated polyimides-polybenzimidazole proton exchange membrane material

A technology of sulfonated polyimide and polybenzimidazole, which is applied in the field of functional polymer materials and electrochemistry, can solve problems such as poor hydrolysis resistance and decreased electrical conductivity, and achieve improved electrical conductivity, improved dimensional stability and The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

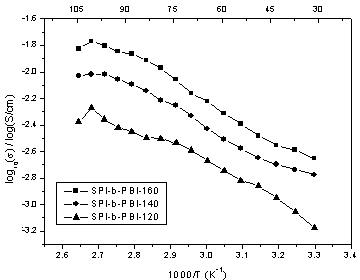

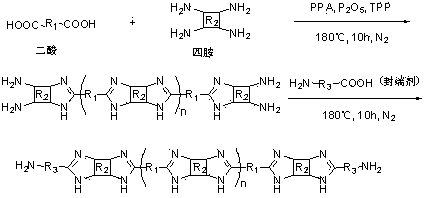

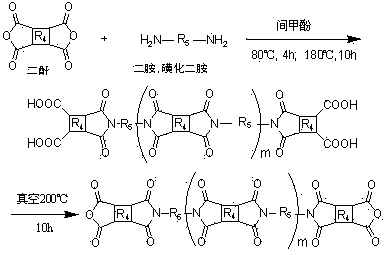

[0031] Synthesis and preparation of block polybenzimidazole-sulfonated polyimide (PBI-b-SPI-80) with sulfonation degree of 80%

[0032] (1) Put 2.1864g (10mmol, 98%) 3,3'-diaminobenzidine (DAB) and 47g polyphosphoric acid in a 250ml three-necked flask, connect nitrogen inlet, drying tube, nitrogen outlet and mechanical stirrer . Start to raise the temperature while feeding nitrogen, and keep it at 150° C. for 30 minutes, so that DAB can be uniformly dispersed and dissolved in polyphosphoric acid. Then add 2.49g (10mmol, 99%) of isophthalic acid (IPA), 0.0352g (0.02564mmol, 99%) of p-aminobenzoic acid (PABA), and add 2.84g (20mmol) of P 2 o 5 In order to enhance the absorption of the reaction product water, drop two drops of triphenylphosphine as a cocatalyst, and keep the reaction at 200°C for 20h. After the temperature of the reaction system is cooled to room temperature, it is poured into deionized water for precipitation, and the polyphosphoric acid is removed by repeate...

Embodiment 2

[0036] Preparation of block polybenzimidazole-sulfonated polyimide (PBI-b-SPI-100) with 100% sulfonation degree

[0037] (1) Put 2.1864g (10mmol, 98%) 3,3'-diaminobenzidine (DAB) and about 50g polyphosphoric acid in a 250ml three-necked flask, connect nitrogen inlet, drying tube, nitrogen outlet and mechanical mixer. Start to raise the temperature while feeding nitrogen, and keep it at 150° C. for 30 minutes, so that DAB can be uniformly dispersed and dissolved in polyphosphoric acid. Then add 2.49g (10mmol, 99%) of isophthalic acid (IPA), 0.0352g (0.02564mmol, 99%) of p-aminobenzoic acid (PABA), and add 4.26g (30mmol) of P 2 o 5 In order to enhance the absorption of water in the reaction product, drop three drops of triphenylphosphine as a cocatalyst and keep it at 200°C for 20 hours. After the temperature of the reaction system is cooled to room temperature, it is poured into deionized water for precipitation, and the polyphosphoric acid is removed by repeated washing. S...

Embodiment 3

[0041] Preparation of Block Polybenzimidazole-Sulfonated Polyimide (PBI-b-SPI-120) with Sulfonation Degree of 120%

[0042] (1) Preparation of amino-terminated PBI-NH 2 (Polymerization degree 40) The reaction process is as follows, put 2.1864g (10mmol, 98%) 3,3'-diaminobenzidine and 63g polyphosphoric acid in a 250ml three-necked flask, connect the nitrogen inlet, drying tube, nitrogen outlet and mechanical stirrer. Start to raise the temperature while feeding nitrogen, and keep it at 150° C. for 30 minutes, so that DAB can be uniformly dispersed and dissolved in polyphosphoric acid. Then add 2.49g (10mmol, 99%) of isophthalic acid (IPA), 0.0352g (0.02564mmol, 99%) of p-aminobenzoic acid (PABA), and add 4.26g (30mmol) of P 2 o 5 In order to enhance the absorption of the reaction product water, drop two drops of triphenylphosphine as a cocatalyst, and keep the reaction at 200°C for 20h. After the temperature of the reaction system is cooled to room temperature, it is poured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com