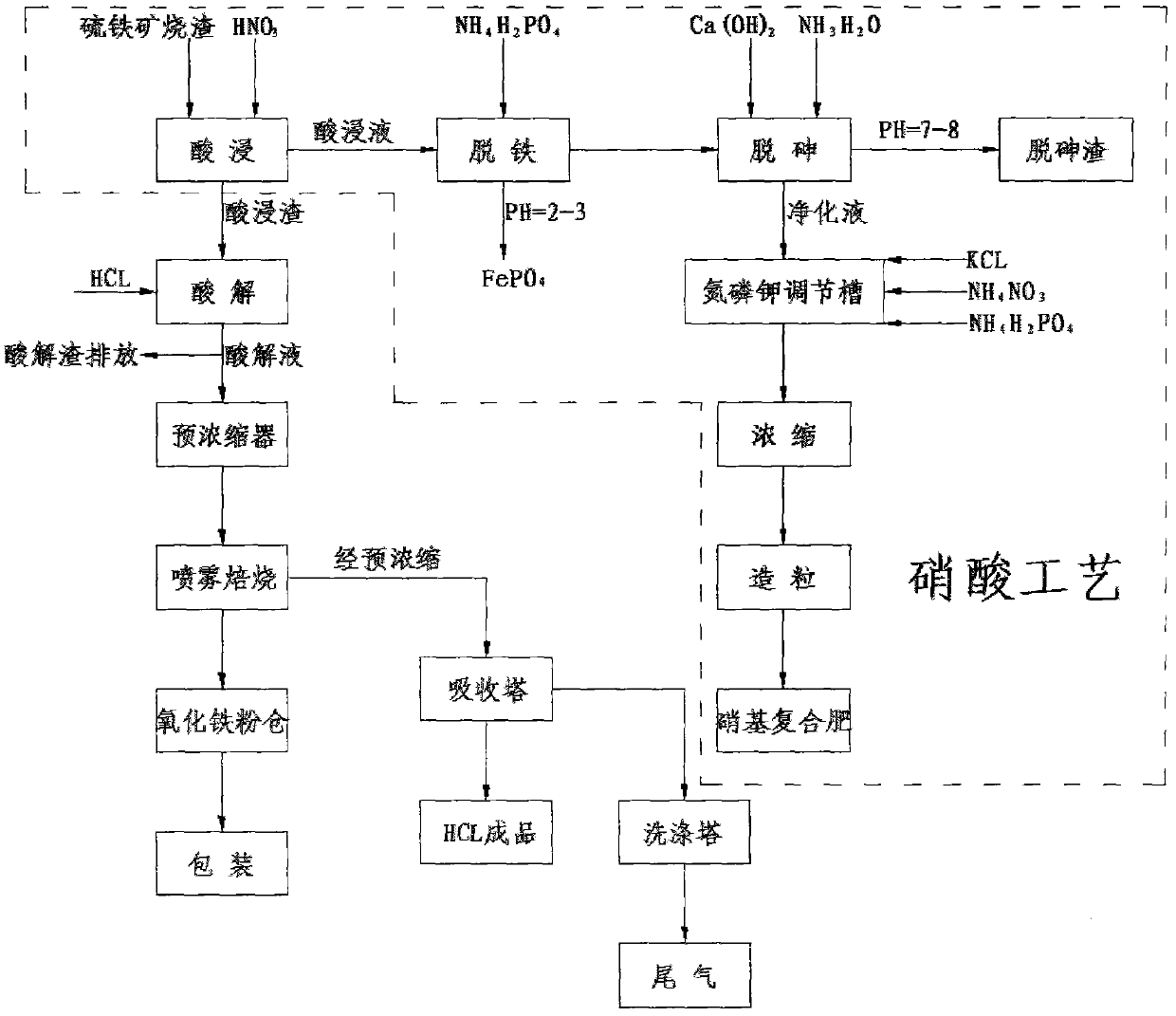

Technique for preparing iron concentrate from pyrite cinder by nitric acid-hydrochloric acid combined treatment

A technology of pyrite slag and iron concentrate, which is applied to the improvement of process efficiency, fertilizer mixture, fertilization device, etc., can solve the problems of secondary pollution, low iron utilization rate, high cost, etc., to achieve the removal of impurities and improve Effect of desulfurization rate and iron loss increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

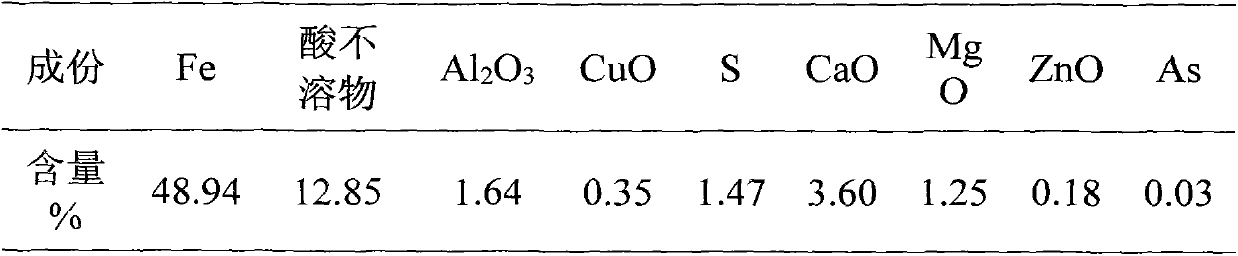

[0045] 1. Main components and content of pyrite cinder

[0046]

[0047] 2. Acid leaching dosage, reaction time, temperature, etc.

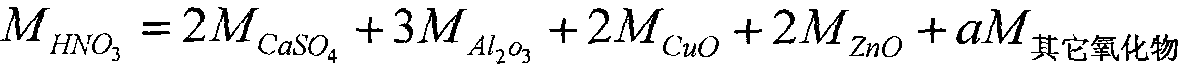

[0048] Calculation of nitric acid dosage:

[0049]

[0050] M - the amount of substance (mol)

[0051] In order to remove impurities to the greatest extent, several times the theoretical amount of nitric acid was used in the test, which is called the excess coefficient of nitric acid and is represented by R.

[0052] Through experiments, it is determined that the optimum technological condition of the acid leaching process is: the concentration of nitric acid is 6mol L -1 , time 60min, temperature 50℃, excess coefficient=15.

[0053] 3. Acid hydrolysis process

[0054] Total iron content in acid leaching residue: 55%, total sulfur content <0.1%

[0055] m HCl = M Fe ×1.1

[0056] The optimized process conditions are determined as: hydrochloric acid concentration 10.6mol L -1 , Reaction time 120min, hydrochloric acid excess coeffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com