Metal substrate based sintering temperature adjustable thick film circuit resistor paste and preparation process thereof

A technology of sintering temperature and metal substrate, which is applied in the manufacture of conductive materials, circuits, and cables/conductors dispersed in non-conductive inorganic materials. It can solve the problems of narrow sintering process window, high cost and poor stability, and achieve sintering performance. Good, stable resistance and uniform temperature field of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

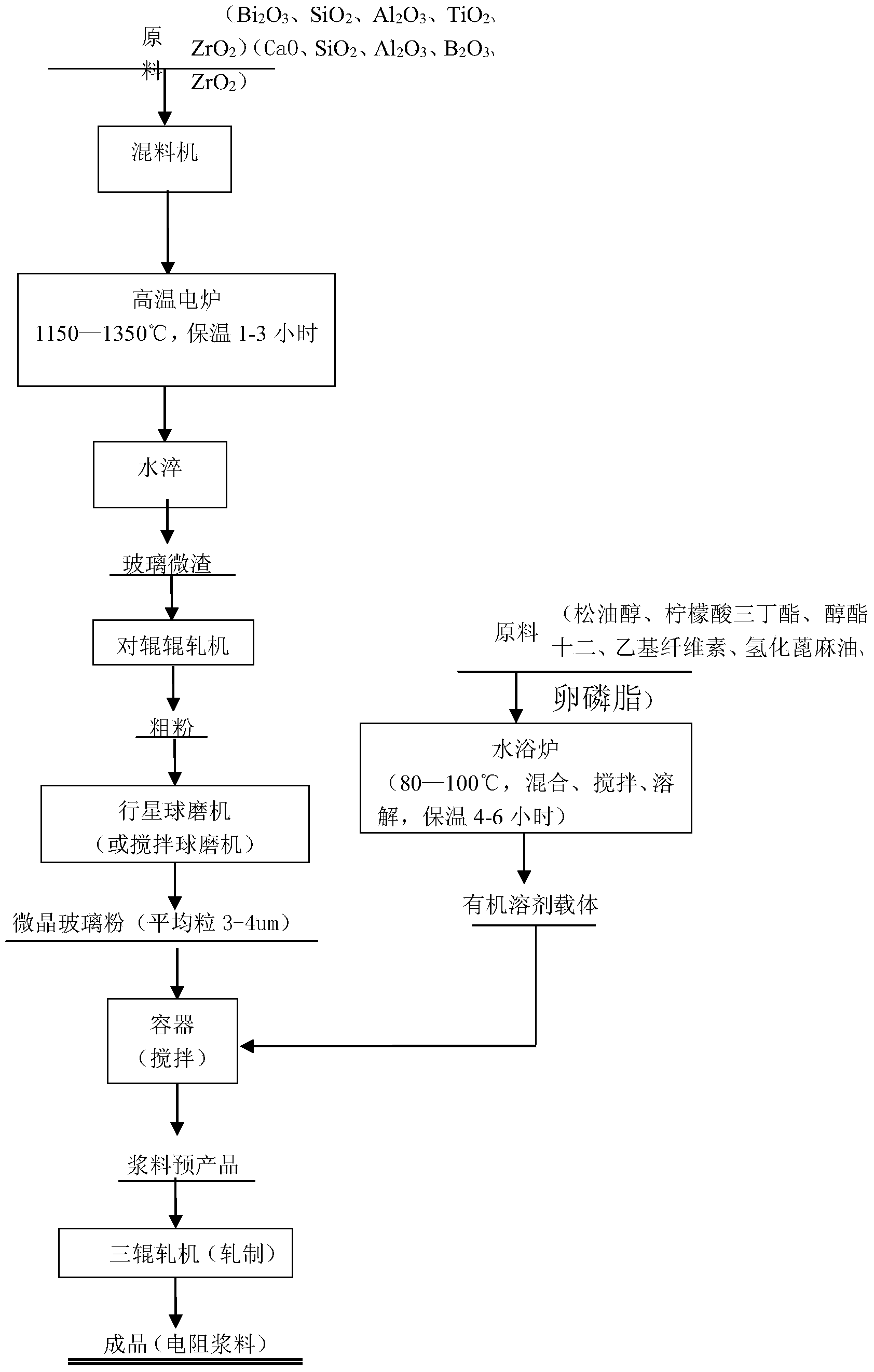

[0020] 1. Two glass-ceramic formulas and preparation processes are: CaO43%, SiO 2 32%, TiO 2 7%, Al 2 o 3 15%, ZrO 2 3%, at 1350°C for 120 minutes; Bi 2 o 3 54%, SiO 2 21%, B 2 o 3 8%, Al 2 o 3 12%, ZrO 2 5% at 1150°C for 120 minutes.

[0021] 2. Preparation of glass powder: crushing on a roller mill → planetary ball mill → the average particle size of the powder is 3-4 μm, and the maximum particle size is less than 31 μm.

[0022] 3. The weight ratio of silver powder and palladium powder is 93:7, and the average particle size of silver-palladium alloy powder is less than 2 μm.

[0023] 4. Organic solvent formula and cooking process: terpineol 68%, tributyl citrate 8%, alcohol ester twelve 15%, ethyl cellulose 3%, hydrogenated castor oil 2%, lecithin 4%.

[0024] 5. Comprehensive pulping: CaO—SiO 2 —TiO 2 —Al 2 o 3 Glass and Bi 2 o 3 —SiO 2 —Al 2 o 3 —B 2 0 3 The system is mixed in a ratio of 6:4; the ratio of silver-palladium alloy powder and glass pow...

Embodiment 2

[0031] 1. Two kinds of glass-ceramic formulations and preparation processes are: CaO52%, SiO 2 25%, TiO 2 4%, Al 2 o 3 13%, ZrO 2 6%, 120 minutes at 1350°C; Bi 2 o 3 42%, SiO 2 33%, B 2 o 3 6%, Al 2 o 3 17%, ZrO 2 2% at 1150°C for 120 minutes.

[0032] 2. Preparation of glass powder: crushing on a roller mill → planetary ball mill → the average particle size of the powder is 3-4 μm, and the maximum particle size is less than 31 μm.

[0033] 3. The weight ratio of silver powder and palladium powder is 96:4, and the average particle size of silver-palladium alloy powder is less than 2 μm.

[0034] 4. Organic solvent formula and cooking process: 77% terpineol, 3% tributyl citrate, 12% alcohol ester twelve, 4% ethyl cellulose, 3% hydrogenated castor oil, 1% lecithin.

[0035] 5. Comprehensive pulping: CaO—SiO 2 —TiO 2 —Al 2 o 3 Glass and Bi 2 o 3 —SiO 2 —Al 2 o 3 —B 2 0 3 The system is mixed at a ratio of 5:5; the ratio of silver-palladium alloy powder and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com