A Low-Energy Two-Phase CO2 Capture Method

A technology of CO2 and low energy consumption, which is applied in the field of two-phase capture of CO2 with low energy consumption, can solve the problems of high energy consumption of calcium carbonate regeneration, in the ascendant of research and development, and low absorption capacity, and achieve fast absorption/desorption speed, excellent thermal stability and Chemical stability and large absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

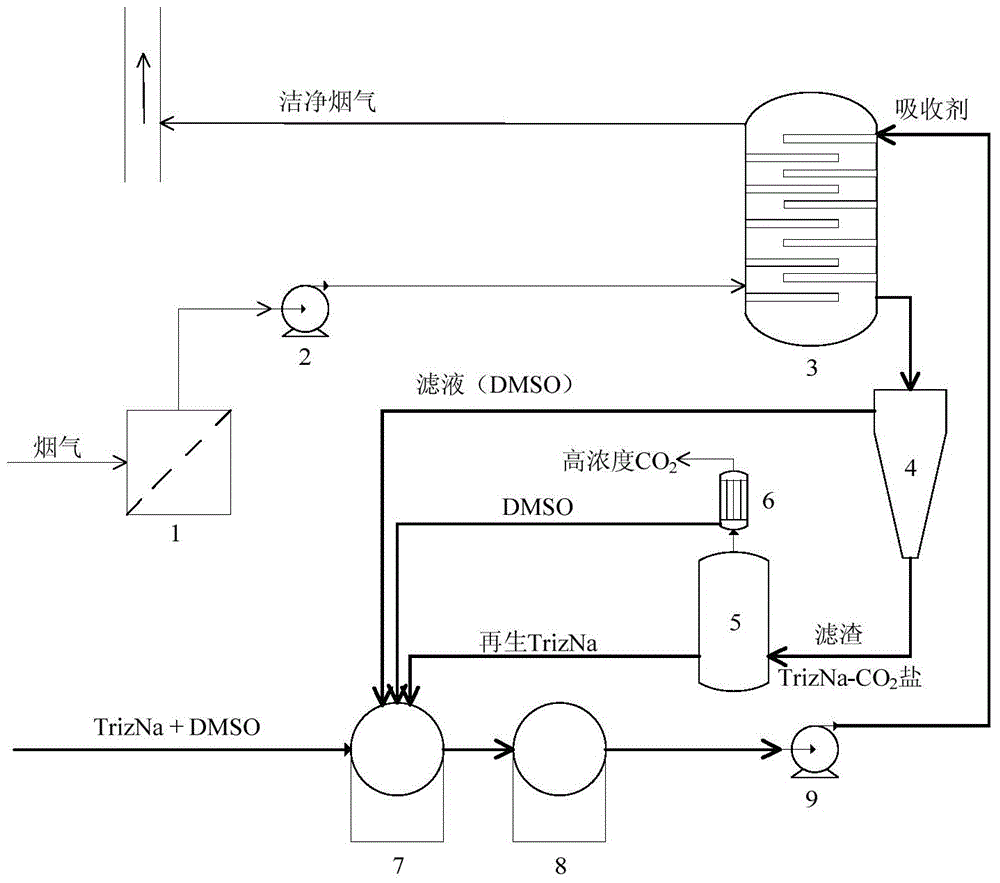

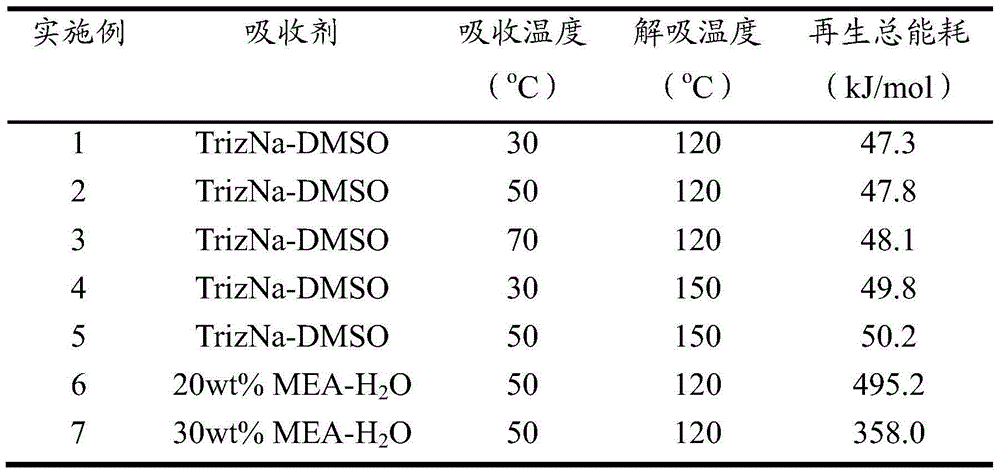

[0029] For CO in TrizNa-DMSO solution system 2 The total regeneration energy consumption of the absorption-desorption process is tested, the absorption condition is 30°C, 1atm, the desorption condition is 120°C, 1atm, according to figure 1 The technological process is carried out, and the total regeneration energy consumption of the TrizNa-DMSO solution system is calculated to be 47.3kJ / molCO 2 .

[0030] The total energy consumption of regeneration consists of three parts: desorption reaction heat, solution evaporation heat and solution sensible heat:

[0031] (1) The absorbent solution absorbs CO 2TrizNa-CO 2 Salt, precipitated out, its desorption enthalpy is 29.7kJ / mol CO 2 , much lower than the desorption enthalpy of ethanolamine (~80.0 kJ / mol).

[0032] (2) TrizNa-CO 2 The DMSO content in the salt is 10wt%, assuming complete volatilization, the calculated heat of vaporization of DMSO is 9.8kJ / mol CO 2 .

[0033] (3) During regeneration, 1 g of TrizNa-CO after cent...

Embodiment 8~13

[0038] To the CO of 5wt% TrizNa-DMSO solution 2 The absorption capacity is tested, the absorption condition is 30°C, 1atm, pure CO 2 atmosphere, CO 2 The flow rate is 50ml / min. CO was measured after 5min 2 The absorption capacity is 27.3mg CO 2 / g solution.

[0039] Under the same test conditions, the CO of different concentrations of TrizNa-DMSO solutions 2 Absorption data are listed in Table 2.

[0040] Table 2

[0041]

Embodiment 14~17

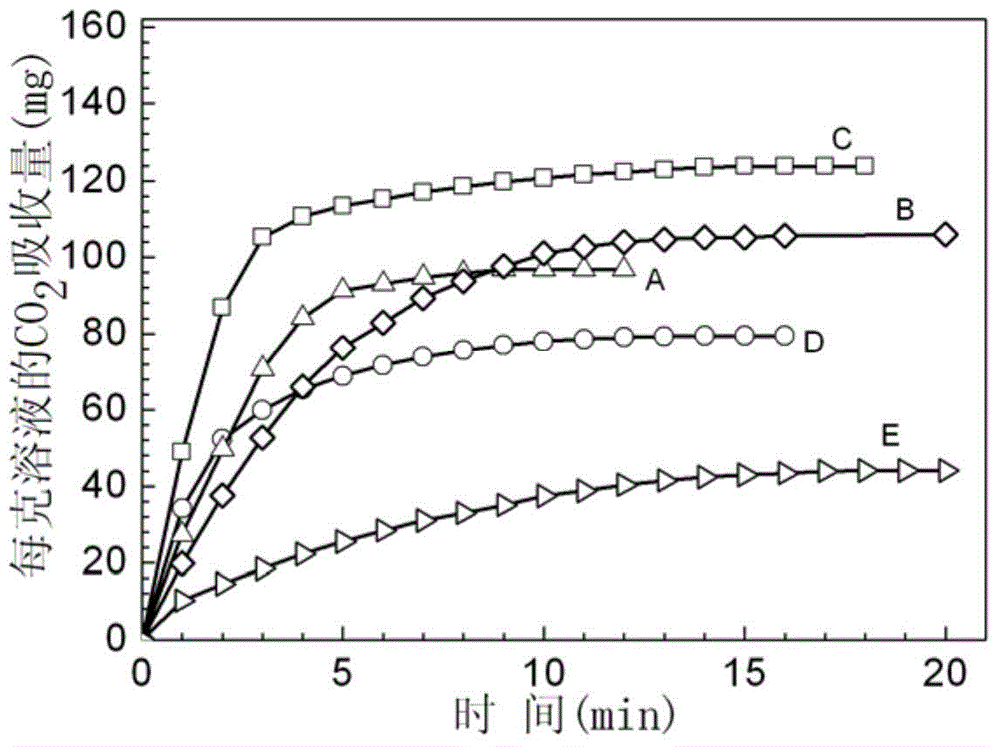

[0043] For 10wt% TrizNa-H 2 CO in O solution system 2 The absorption capacity is tested, the absorption condition is 30°C, 1atm, pure CO 2 atmosphere, CO 2 The flow rate is 50ml / min. CO was measured after 25min 2 The absorption capacity is 37.1mg CO 2 / g solution.

[0044] Under the same test conditions, the CO of the TrizNa solution system (where the mass fraction of TrizNa is 10wt%) prepared by different solvents 2 Absorption data are listed in Table 3.

[0045] table 3

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com