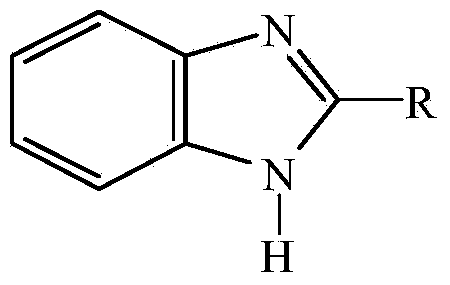

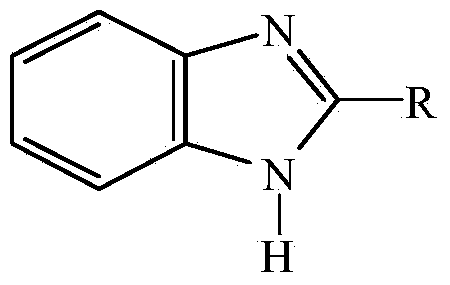

Method for preparing 2-alkyl benzimidazole compound

A technology of alkylbenzimidazole and compound, which is applied in the field of chemical synthesis, can solve problems such as long time and high temperature, and achieve the effects of short reaction time, low reaction temperature and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

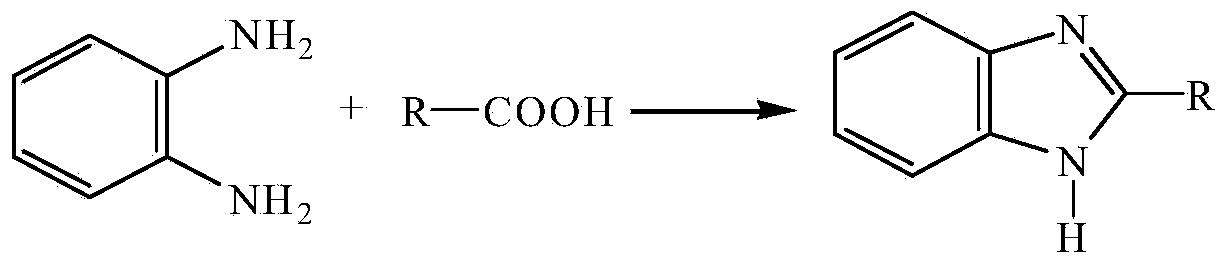

Method used

Image

Examples

Embodiment 1

[0028] 1) Add a mol o-phenylenediamine and b mol formic acid (R=H) to a dry mortar, grind for 5 min, let stand for 20 min, then grind for 10 min, stand for 30 min, and grind for 15 min at 20°C. Let stand for 40 minutes to mix the raw materials uniformly and react the raw materials, where a:b=1:1;

[0029] 2) Place the mortar in an oven to continue the reaction of the raw materials. First, react at 50°C for 30 minutes, then increase the temperature to 80°C, react at 80°C for 60 minutes, and finally increase the temperature to 100°C and react at 100°C for 90 minutes to obtain the reaction mixture;

[0030] 3) Cool the reaction mixture to room temperature to obtain a suspension, adjust the pH of the suspension to 8.5 with a 5% mass concentration NaOH solution, and then wash it with water (directly add water to the pH-adjusted suspension ), suction filtration, the obtained filter cake is the crude product, and the crude product is recrystallized with absolute ethanol to obtain benzimi...

Embodiment 2

[0034] 1) Add a mol o-phenylenediamine and b mol acetic acid to a dry mortar (R=CH 3 ), at 25℃, first grind for 6min, stand for 15min, then grind for 10min, stand for 28min, finally grind for 18min, stand for 38min, make the raw materials mix uniformly, and make the raw materials react, where a:b=1:1 ;

[0035] 2) Place the mortar in an oven to continue the reaction of the raw materials, first react at 48°C for 35 minutes, then increase the temperature to 80°C, react at 80°C for 60 minutes, and finally increase the temperature to 100°C and react at 100°C for 90 minutes to obtain the reaction mixture;

[0036] 3) Cool the reaction mixture to room temperature to obtain a suspension, adjust the pH of the suspension to 8 with a 4% NaOH solution by mass concentration, then wash it with water and filter with suction. The obtained filter cake is the crude product. The crude product is recrystallized with absolute ethanol to obtain 2-methylbenzimidazole with a yield of over 90%. The struc...

Embodiment 3

[0040] 1) Add a mol o-phenylenediamine and b mol propionic acid to a dry mortar (R=C 2 H 5 ), at 22°C, first grind for 4 min, let stand for 18 min, then grind for 8 min, let stand for 26 min, and finally grind for 20 min, let stand for 35 min, so that the raw materials are mixed uniformly, and the raw materials are reacted, where a:b=1:1 ;

[0041] 2) Place the mortar in an oven to continue the reaction of the raw materials, first react at 52°C for 25 minutes, then increase the temperature to 78°C, react at 78°C for 55 minutes, and finally increase the temperature to 98°C and react at 98°C for 95 minutes to obtain a reaction mixture;

[0042] 3) Cool the reaction mixture to room temperature to obtain a suspension. Use a 3% NaOH solution to adjust the pH of the suspension to 9, then wash it with water and filter with suction. The resulting filter cake is the crude product. The crude product is recrystallized with absolute ethanol to obtain 2-ethylbenzimidazole with a yield of over ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com