Rubber slab with anticorrosion lining special for sodium hypochlorite

A sodium hypochlorite and anti-corrosion technology, which is applied in the field of anti-corrosion rubber sheets, can solve problems such as high investment cost, high price, and stainless steel materials cannot resist its corrosion, so as to reduce environmental pollution, reduce production costs, and avoid personal injury accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

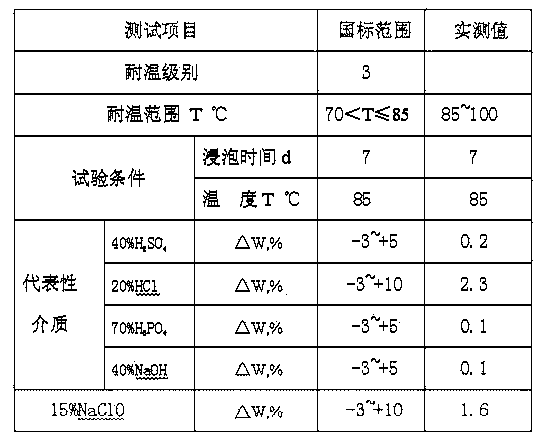

[0007] Sodium hypochlorite-resistant anti-corrosion lining rubber sheet is characterized in that: the weight ratio of each main and auxiliary raw material is as follows: butyl rubber: 100 parts, carbon black N774: 30-40 parts, carbon black N990: 40-50 parts, hard Fatty acid: 3-8 parts, polyethylene wax: 6-10 parts, barium sulfate: 15-20 parts, paraffin oil: 4-8 parts, rosin: 6-10 parts, accelerator TT: 1-2 parts. In practice, in the production process of anti-corrosion lining rubber sheets, in order to prevent the oxidation of oxygen in the air, some antioxidants are usually added, but in order to ensure the processing performance, there are certain restrictions on the ratio. Medium, there is no tolerance, so choosing a suitable rubber variety and designing a suitable formula to improve the processing performance is the key to solving the above problems. Among natural rubber and synthetic rubber, the comprehensive performance of synthetic rubber is better than that of natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com