Drainage crack resistance based old road expansion splicing structure and method

A technology of pavement structure and old road, which is applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems of driving safety impact, deflection settlement, cracking at joints, etc. The effect of speeding up construction and broadening the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

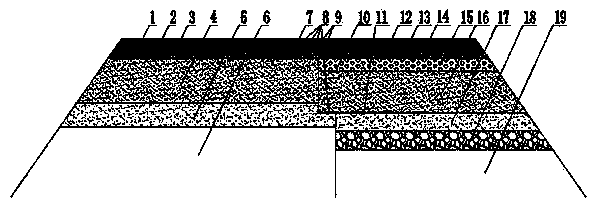

[0025] 1. Determine the specific structure of the old road

[0026] The specific structure of the old road is 4cmSMA-13 (upper asphalt surface layer 1) + 6cmAC-20C (middle asphalt surface layer 2) + 7cmAC-25C (lower asphalt surface layer 3) + 36cm cement stabilized gravel base 4 (constructed in two layers, The upper and lower bases are each 18cm) + 20cm lime stabilized soil subbase 5 + old roadbed 6.

[0027] 2. Layered milling of the old road structure layer

[0028] The seams of the new and old roads are set on the center line of the outer marking line of the outer lane of the old road 7 . Carry out layered milling on the old road structure layer from the splicing seam 7 to the outside, corresponding to the old road pavement structure, and reserve a certain width of the structure layer splicing steps 8 for milling.

[0029] The step widths corresponding to the middle asphalt surface course 2, the lower asphalt surface course 3, the cement stabilized macadam base course 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com