Solar heat exchanger and wall-mounted pressure-bearing tankless solar water heater

A technology of heat exchanger and solar energy, which is applied in the field of light-to-heat conversion devices, can solve the problems that the installation method affects the normal maintenance of the house, does not adapt to the wall-mounted installation method, and increases the greenhouse effect of the atmosphere, so as to save living space, suitable for promotion and application, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

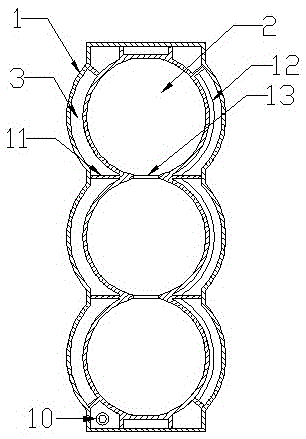

[0028] Such as figure 1 , figure 2 As shown, the solar heat exchanger has a heat exchange water storage bin 2, and a plurality of cavities are arranged in the heat exchange water storage bin 2. In this embodiment, three cavities are taken as an example. The cavities communicate with each other through holes 13. The surrounding surface of the water storage tank 2 is provided with a vacuum interlayer 3, and a support rib 11 is provided between the vacuum interlayer panel 1 and the heat exchange water storage tank 2, and the support rib 11 is integrated with the heat exchange water storage tank 2, and the vacuum interlayer panel 1 and the heat exchange The material of the water storage tank 2 is polymethyl methacrylate, polycarbonate or polystyrene. In this embodiment, polymethyl methacrylate is used, which has a temperature resistance of -40°C to 105°C and a light transmittance of 93%. Acid-base, non-toxic and environmentally friendly. The light-receiving surface of the vacuu...

Embodiment 2

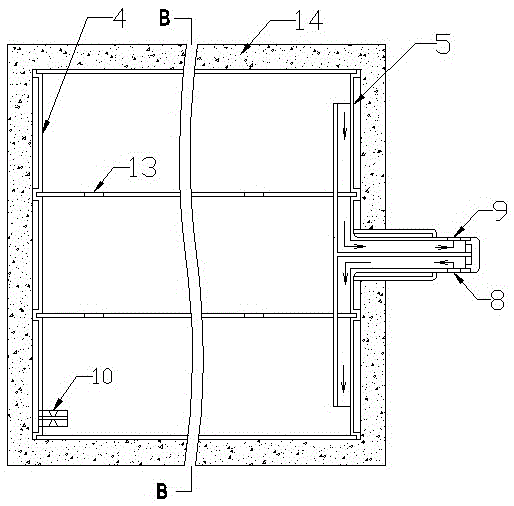

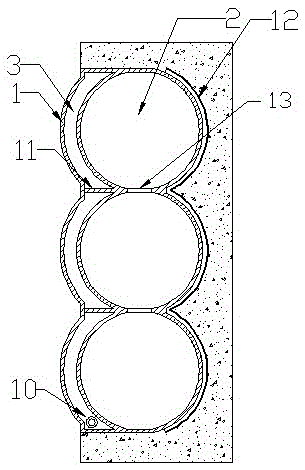

[0031] Such as image 3 , Figure 4 As shown, the solar heat exchanger has a heat exchange water storage bin 2, and a plurality of cavities are arranged in the heat exchange water storage bin 2. In this embodiment, three cavities are taken as an example. The cavities communicate with each other through holes 13. The light-receiving surface of the water storage tank 2 is provided with a vacuum interlayer 3, and the material of the vacuum interlayer panel 1 and the heat exchange water storage tank 2 is polymethyl methacrylate, polycarbonate or polystyrene, and polycarbonate is used in this embodiment, and its temperature resistance -40℃~105℃, the light transmittance is 90%, acid and alkali resistance, environmental protection and non-toxic. The light-receiving surface of the vacuum interlayer panel 1 is a plurality of curved surfaces with equal arc lengths, the transition section of the two adjacent curved surfaces and the transition section of the outer curved surface are plan...

Embodiment 3

[0034] Such as Figure 5 As mentioned above, a plurality of solar heat exchangers 15 in Embodiment 2 (or Embodiment 3) are combined through connectors to form a wall-mounted pressure-bearing tankless solar water heater. In this embodiment, 4 solar heat exchangers are used. And for the upper and lower double-layer structure 。 Described connector comprises connecting pipe 17, is located at the temperature sensor 23 on connecting pipe 17, is located at the pressure stabilizing valve 18 of connecting pipe 17 inlet side, is wrapped in the insulating layer 16 outside connecting pipe 17, and described connecting pipe 17 is made of Three pipes are connected in parallel, wherein the middle pipeline is connected in series with the solenoid valve 19, the antifreeze circulation pump 20, and the auxiliary electric heater 21, and the lead ends of the solenoid valve 19, the antifreeze circulation pump 20, and the auxiliary electric heater 21 are connected in series. It is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com