Animal feed and preparation method thereof

A feed and ruminant technology, applied in animal feed, animal feed, applications, etc., can solve the problems of reducing dietary N utilization and achieve the effect of increasing milk protein content, increasing total milk production, and increasing milk production of dairy cows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

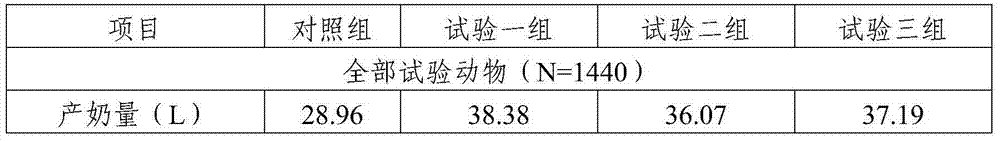

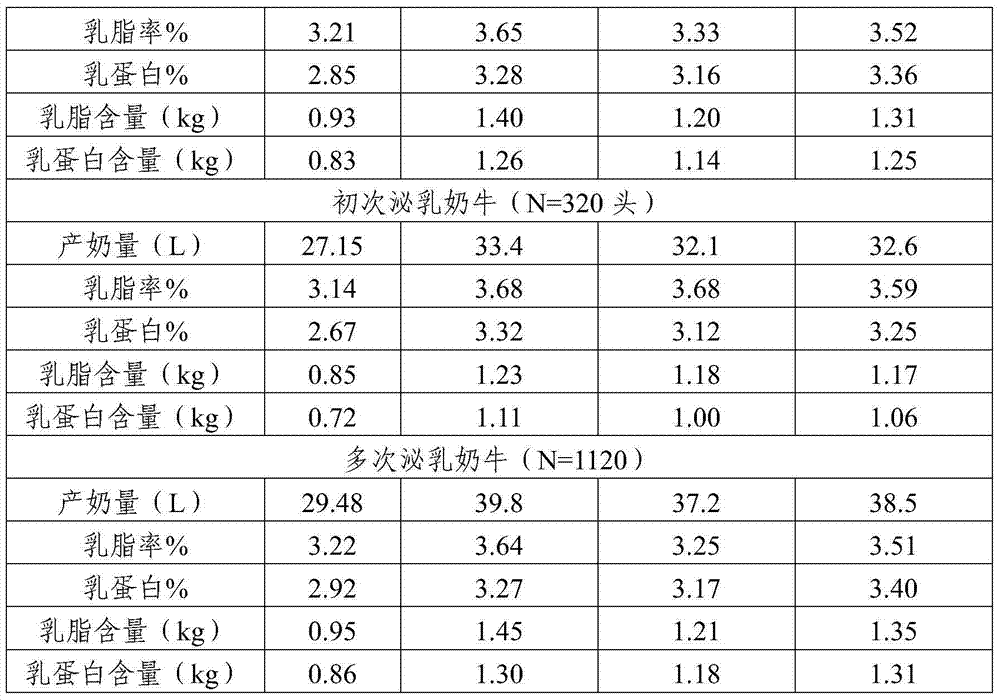

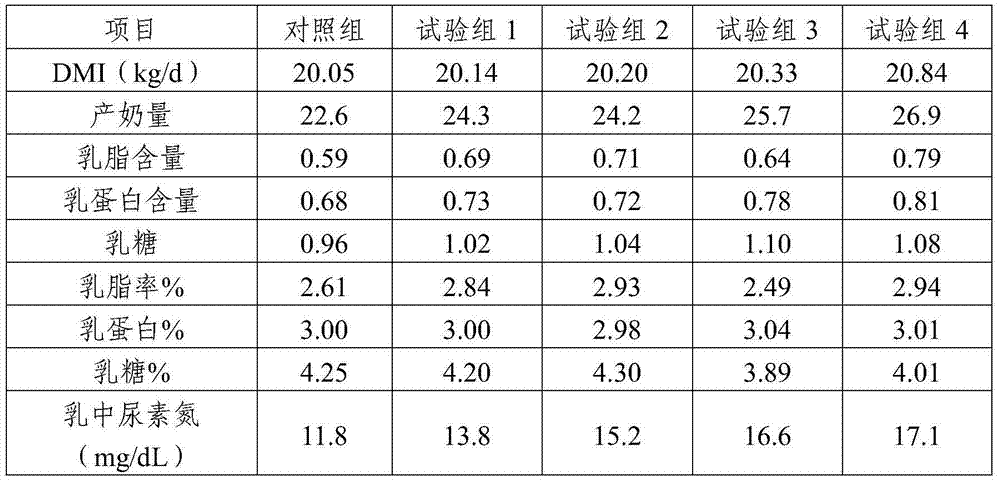

Examples

Embodiment 1

[0029] According to the ruminant feed of the present invention, the preparation method of the feed is:

[0030] 1) Soak the corn in an aqueous solution containing 0.5% lauric acid for 48 hours at 55°C (the aqueous solution should only submerge the corn), dry it below 60°C, and crush it through a 40-mesh sieve to obtain acidified corn;

[0031] 2) According to weight parts SiO 2 67. FeO 3 12. The ratio of CaO13 and MgO8 is mixed evenly to obtain mineral premix;

[0032] 3) Weigh corn 7.5, acidified corn 2, wheat bran 1.1, secondary flour 1.1, soybean meal 2.1, salt 0.2, bone meal 0.5, puffed soybean 2.4, cottonseed cake 4, fish meal 0.6, mineral premix 5 and weigh in parts by weight well mixed;

[0033] 4) Weigh selenium-enriched Saccharomyces cerevisiae subsp. boulardii CGMCC No.8447 bacterial powder 57, Bacillus subtilis CGMCC No.4628 bacterial powder 16, Bacillus pumilus CGMCC No.4756 bacterial powder 21, non-starch polysaccharide Degrading enzyme 2 and fibrinolytic enzy...

Embodiment 2

[0038] According to dairy cow feed of the present invention, the preparation method of described feed is:

[0039] 1) Soak the corn in an aqueous solution containing 0.5% lauric acid for 48 hours at 55°C (the aqueous solution should only submerge the corn), dry it below 60°C, and crush it through a 40-mesh sieve to obtain acidified corn;

[0040] 2) According to weight parts SiO 2 60. FeO 3 15. The ratio of CaO15 and MgO10 is mixed evenly to obtain a mineral premix;

[0041] 3) Weigh corn 5.5, acidified corn 4, wheat bran 1.1, secondary flour 1.1, soybean meal 2.1, salt 0.2, bone meal 0.5, puffed soybean 2.4, cottonseed cake 4, fish meal 0.6, mineral premix 5 and weigh in parts by weight well mixed;

[0042] 4) Weigh selenium-enriched Saccharomyces cerevisiae subspecies boulardii CGMCC No.8447 bacterial powder 40, Bacillus subtilis CGMCC No.4628 bacterial powder 25, Bacillus pumilus CGMCC No.4756 bacterial powder 30, non-starch polysaccharide Degrading the enzyme 2 and the...

Embodiment 3

[0047] According to dairy cow feed of the present invention, the preparation method of described feed is:

[0048] (1) Soak the corn in an aqueous solution containing 0.5% lauric acid for 48 hours at 55°C (the aqueous solution can submerge the corn), dry it below 60°C, and crush it through a 40-mesh sieve to obtain acidified corn;

[0049] (2) According to weight parts SiO 2 67. FeO 3 12. The ratio of CaO13 and MgO8 is mixed evenly to obtain mineral premix;

[0050] 3) Weigh corn 8.5, acidified corn 1, wheat bran 1.1, secondary flour 1.1, soybean meal 2.1, salt 0.2, bone meal 0.5, puffed soybean 2.4, cottonseed cake 4, fish meal 0.6, mineral premix 5 and weigh in parts by weight well mixed;

[0051] 4) Weigh selenium-enriched Saccharomyces cerevisiae subspecies boulardii CGMCC No.8447 bacterial powder 50, Bacillus subtilis CGMCC No.4628 bacterial powder 20, Bacillus pumilus CGMCC No.4756 bacterial powder 25, non-starch polysaccharide Degrading the enzyme 5 and the fibrinol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com