System for treating tail gas produced by white carbon black production by gas phase method

A technology for tail gas treatment and silica, applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of blockage of packing holes, reduce production costs, and affect the absorption of hydrogen chloride, so as to reduce material loss and improve Absorption efficiency, ensuring the effect of up-to-standard discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

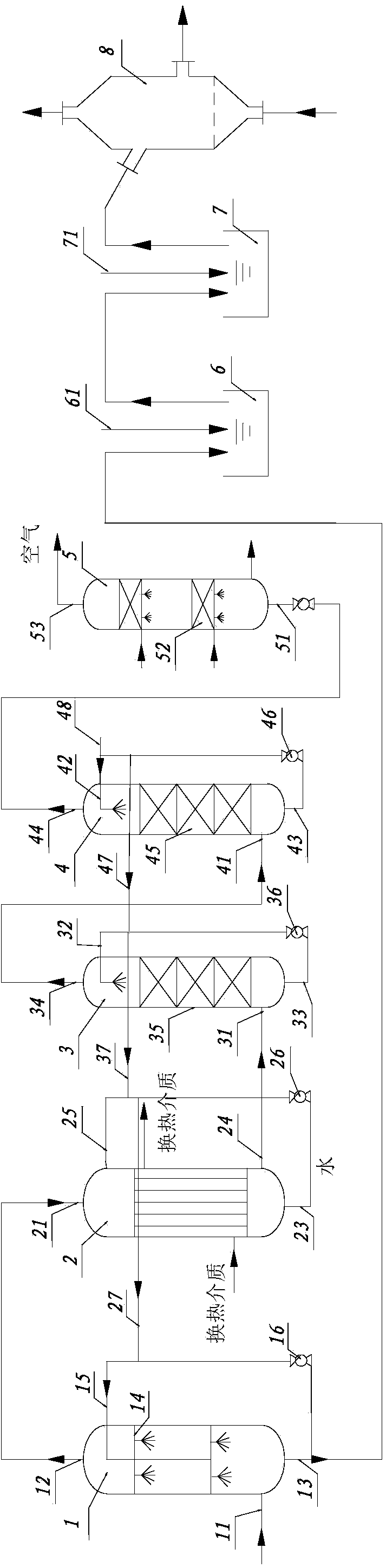

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Such as figure 1 Shown a kind of gas phase method to produce white carbon black tail gas treatment system, this system comprises washing tower 1, falling film tower 2, the first hydrochloric acid washing tower 3, the second hydrochloric acid washing tower 4, alkali washing tower 5, acidification tower 6, Neutralization tower 7 and fluidized bed dryer 8. The bottom of described washing tower 1 is provided with the inlet 11 of white carbon black powder by-product mixed gas, and the inside of washing tower 1 is provided with two sets of described washing spraying devices 14 from top to bottom, and the bottom of washing tower 1 is provided with There is a washing liquid outlet 13, the top of the washing tower 1 is provided with a washing liquid inlet 15, the top of the washing tower 1 is provided with a washing tower gas outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com