Method for preparing hemicellulose/nano-silver colloid rapidly

A nano-silver sol, hemicellulose technology, applied in the nano field, can solve the problems of inability to provide basic data and theoretical basis, limit the application of hemicellulose, insufficient physical and chemical properties of hemicellulose, etc. The effect of functionalization and high-value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

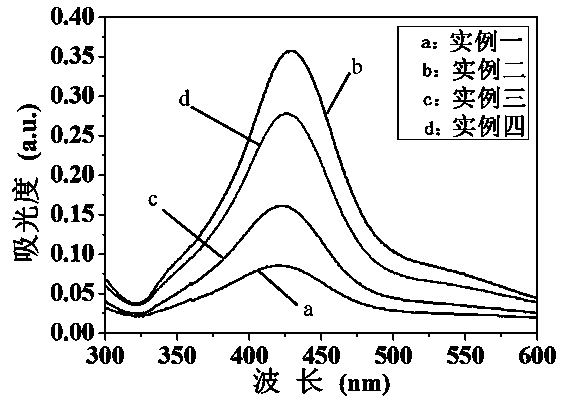

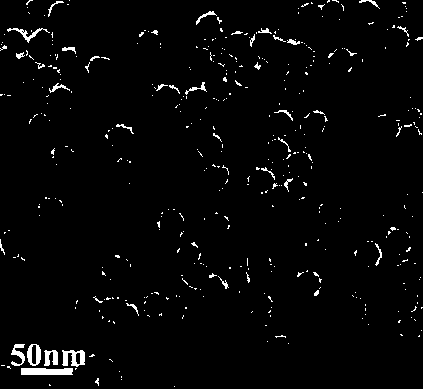

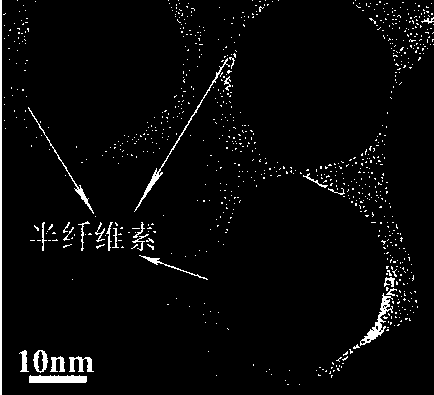

Embodiment 1

[0028] 0.1020 g of AgNO 3 Dissolved in 20 mL deionized water to make 5.10 mg / mL AgNO 3 aqueous solution, 80 mg / mL NaOH aqueous solution was added dropwise to the AgNO 3 solution until the precipitation no longer increases, and then immediately drop 100 mg / mL ammonia water until the precipitation just dissolves, forming solution. Prepare a sodium hydroxide solution with a mass percentage of 1%, and hemicellulose (extracted from gramineous plants, whose weight-average molecular weight is 4.8×10 4 g / mol, the sugar composition is 86.00% xylose, 11.00% arabinose, 0.60% glucose, 0.20% galactose, 0.10% mannose and 2.50% glucuronic acid) dissolved in 20 mL sodium hydroxide solution In, a 1.5% (w / v) hemicellulose sodium hydroxide solution was prepared. After stirring evenly, place it in a microwave reactor, adjust the microwave radiation power to 700 W, and the radiation temperature to 50 °C; The solution is dropped into the hemicellulose solution, at this time the hemicellulos...

Embodiment 2

[0032] 0.1326 g of AgNO 3 Dissolved in 20 mL deionized water to make 6.63 mg / mL AgNO 3 aqueous solution, 80 mg / mL NaOH aqueous solution was added dropwise to the AgNO 3 solution until the precipitation no longer increases, then immediately drop 200 mg / mL of ammonia water until the precipitation just dissolves, forming solution. Prepare a sodium hydroxide solution with a mass percentage of 2%, and hemicellulose (extracted from gramineous plants, whose weight-average molecular weight is 5.0×10 4 g / mol, the sugar composition is 87.00% xylose, 10.00% arabinose, 0.70% glucose, 0.30% galactose, 0.12% mannose and 2.15% glucuronic acid) dissolved in 30 mL sodium hydroxide solution In , a 1 % (w / v) hemicellulose sodium hydroxide solution was prepared. After stirring evenly, place it in a microwave reactor, adjust the microwave radiation power to 800 W, and the radiation temperature to 60 °C; The solution is dropped into the hemicellulose solution, at this time the hemicellulose...

Embodiment 3

[0036] 0.4080 g of AgNO 3 Dissolved in 20 mL deionized water to make 20.40 mg / mL AgNO 3 aqueous solution, 80 mg / mL NaOH aqueous solution was added dropwise to the AgNO 3 solution until the precipitation no longer increases, and then immediately drop 400 mg / mL of ammonia water until the precipitation just dissolves, forming solution. Prepare a sodium hydroxide solution with a mass percentage of 3%, hemicellulose (extracted from gramineous plants, its weight-average molecular weight is 5.2×10 4 g / mol, the sugar composition is 88.00% xylose, 9.00% arabinose, 0.80% glucose, 0.40% galactose, 0.13% mannose and 1.75% glucuronic acid) dissolved in 40 mL sodium hydroxide solution In, a 0.75% (w / v) hemicellulose sodium hydroxide solution was prepared. After stirring evenly, place it in a microwave reactor, adjust the microwave radiation power to 900 W, and the radiation temperature to 70 °C; The solution is dropped into the hemicellulose solution, at this time the hemicellulose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com