Foam concrete block for building enclosure structure and preparation method thereof

A foam concrete and envelope structure technology, applied in the field of building materials, can solve the problems of increasing the weight of the building itself and construction costs, large one-time investment, and difficulties for small and medium-sized enterprises, and achieve good thermal insulation performance, low investment, and small bulk density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

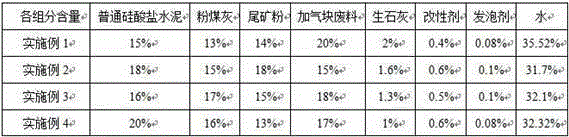

[0018] The preparation method of the foamed concrete block for building envelope structure provided by the invention comprises the following steps: (1) prepare raw materials by weight percentage in Table 1, first raw materials ordinary Portland cement, fly ash, tailings powder, Put the aerated block waste, quicklime and modifier into the mixer, add water and stir for 3-5 minutes. Stir at a speed of 1.5-2 minutes to obtain the slurry; (2) Open the discharge valve, put the slurry into the mold and stop foaming for 20-30 minutes, and release the mold after 6 hours with the solidification of the slurry. The plastic film is covered in the solar curing room for 48 hours of moisturizing and curing, and then it is cut and packaged to be the primary product. The primary product needs to be naturally cured in the yard for more than 28 days to become the final product.

[0019] Raw material ratio (percentage by weight) of each embodiment of table 1

[0020]

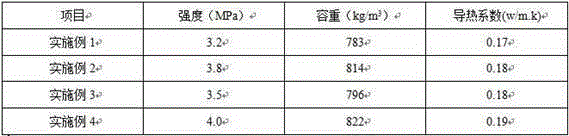

[0021] The performance i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com