Preparation method of ferropericlase

An iron periclase and atmosphere technology is applied in the field of preparation of iron periclase, which can solve the problems of harsh ultra-high pressure synthesis conditions, inconvenient experimental research, long sintering cycle, etc., and achieves stable and easy operation of sintering process, simple sintering equipment, The effect of low sintering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] (Mg 0.9 Fe 0.1 ) The preparation method of O, completes steps as follows:

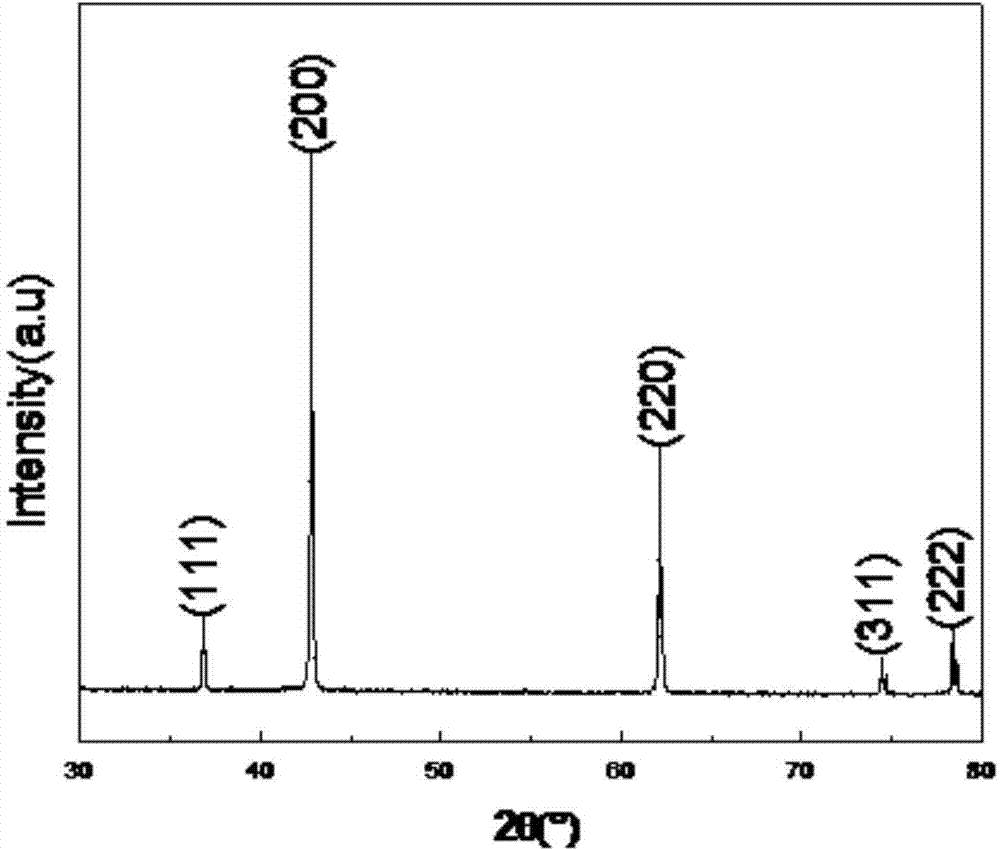

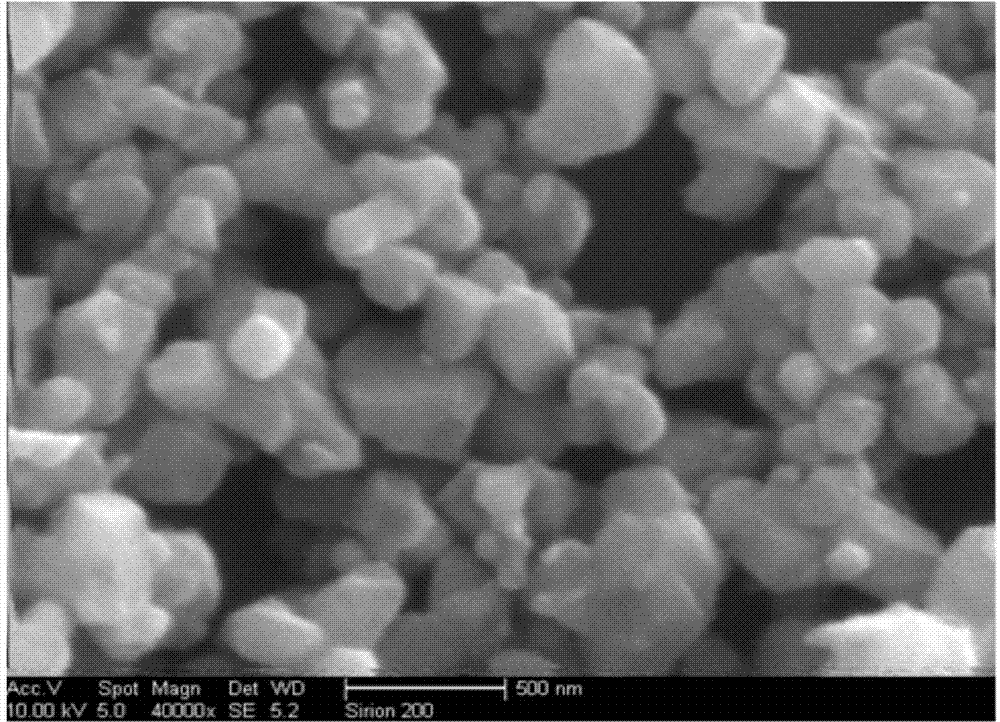

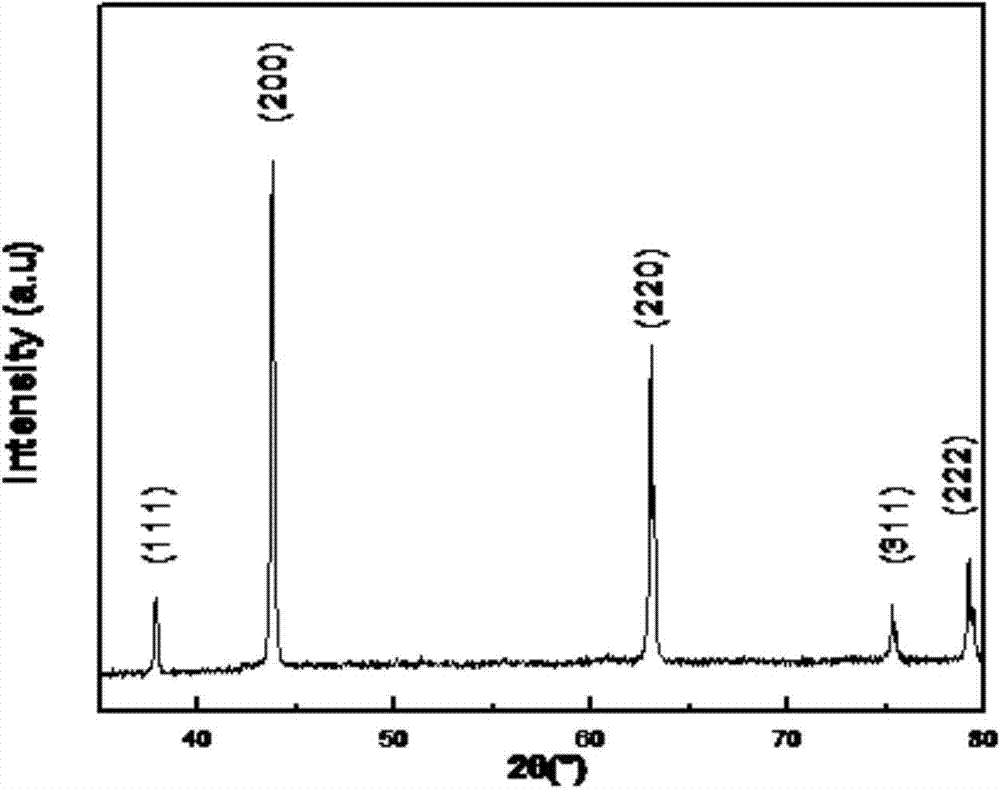

[0019] Starting materials are MgO powder and Fe 2 o 3 Powder, weighing 25.0405g and 5.5118g respectively, put them in a ball mill jar, add 60mL of absolute ethanol, ball mill at a speed of 250r / min for 20h, then place in an oven to dry at 60°C for 10h, grind and pass through 100 mesh After sieving, the precursor powder was obtained; the resulting precursor powder was placed in an alumina crucible, in a tube furnace, in CO 2 -H 2 High-temperature reduction reaction in a mixed gas (ratio: 2:1) atmosphere, the heating and cooling rate is 4°C / min, the reaction temperature is 1200°C, and the holding time is 10h. After three repetitions of high-temperature reaction treatment, grinding, and sieving, the obtained Pure phase (Mg 0.9 Fe 0.1 )O submicron powder, the XRD pattern of the powder is shown in figure 1 , SEM image see figure 2 . from figure 1 It can be seen that the powder is a pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com