Thermoplastic elastomer composition for preparing soft printing materials for three-dimensional printing rapid prototyping

A thermoplastic elastomer and three-dimensional printing technology, applied in the field of thermoplastic elastomer compositions, can solve problems such as no ductility, lack of soft feel, and unsmooth printing, so as to achieve easy process operation, wide range of raw material acquisition, and improved printing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

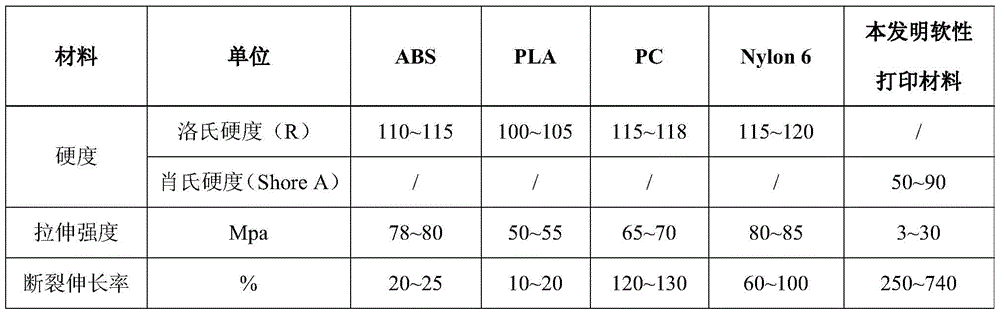

[0076] In an exemplary embodiment, the thermoplastic elastomer composition used for preparing soft printing materials for three-dimensional printing fused deposition rapid prototyping according to the present invention includes the following components by weight percentage:

[0077] thermoplastic elastomer 30.0%~43.8% polyolefin 11.8%~40.1% softener 29.5%~44.0% lubricant 0.1% antioxidant 0.3%

[0078] The thermoplastic elastomer is selected from any of the above-mentioned thermoplastic elastomers, preferably a styrene-based thermoplastic elastomer, such as SEBS, which can be a combination of Kraton G1650 and Kraton G1651, and the weight ratio of the two can be 1:1, as in Example 1 ~5 described.

[0079] The polyolefin is selected from polypropylene, polyethylene and other olefin oligomers. Polypropylene is preferred.

[0080] The softening agent is selected from white mineral oil, paraffin oil, silicone oil, castor oil, palm oil, epoxidi...

Embodiment 1~ Embodiment 5

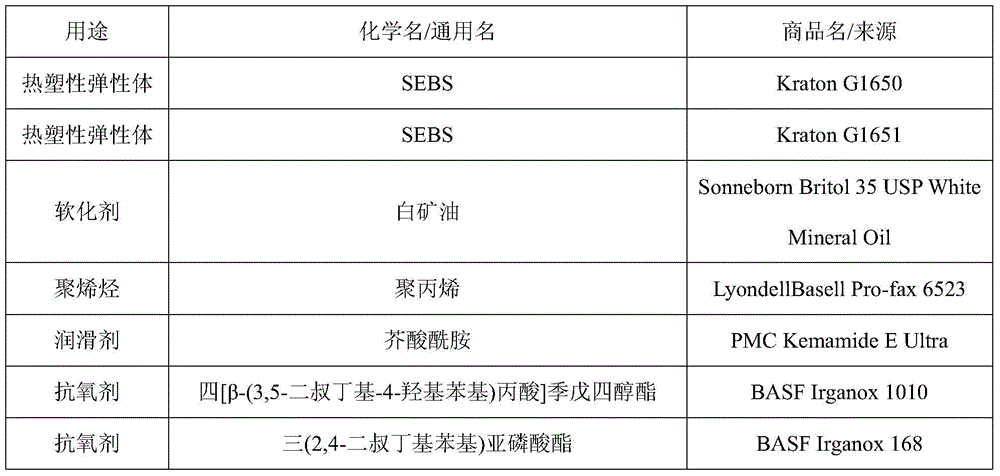

[0118] 1. Materials and their sources: as shown in Table 2.

[0119] Table 2:

[0120]

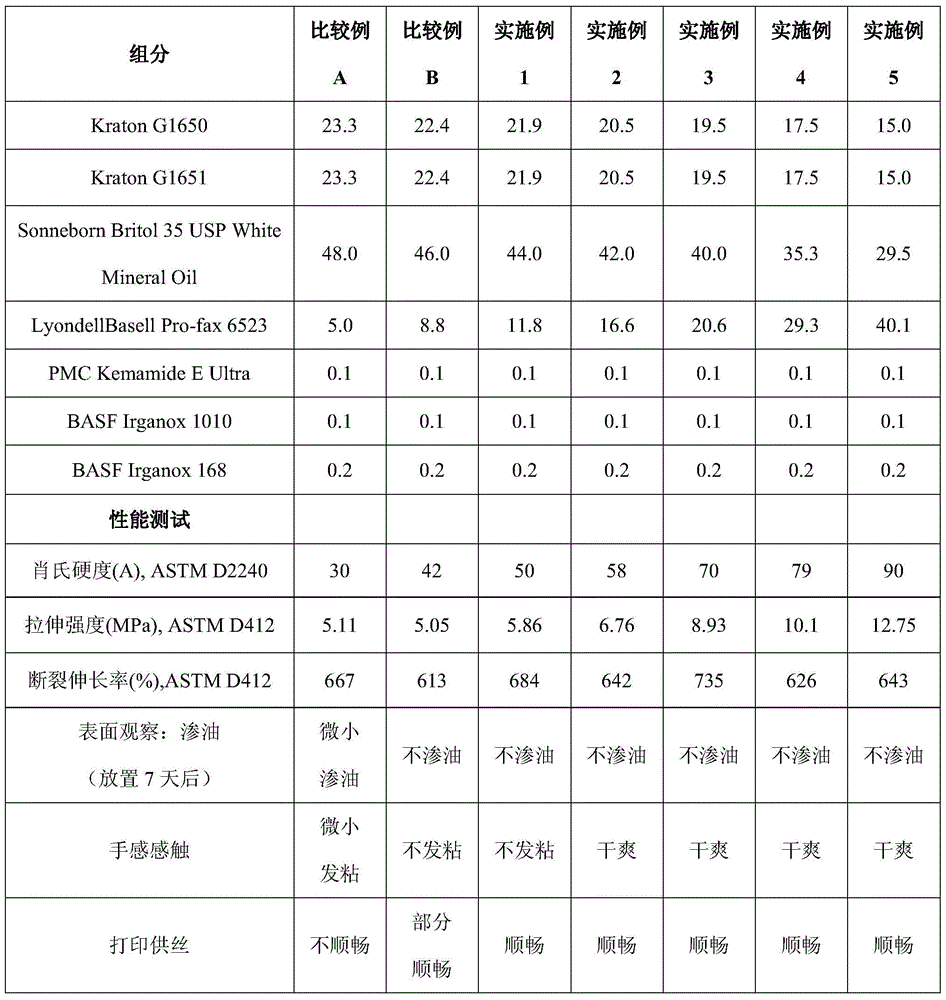

[0121] 2. Formulation, preparation method and performance test

[0122] Formula and performance test: as shown in Table 2.

[0123] Preparation method: according to the dosage ratio shown in Table 3, put each component in a mixer, fully mix under normal temperature conditions to form a uniformly mixed material, and put it into the compound with a length-to-diameter ratio (L / D) of 44 or more Parallel twin-screw extruder, melting and plasticizing at 180-220°C to form a melt; the melt is further uniformly mixed, extruded through the mouth of the parallel twin-screw extruder, and then using a commonly used underwater pelletizer Granulation is carried out to obtain soft printing materials in the form of soft particles.

[0124] The above-mentioned soft particles are plasticized and melted again by a common single-screw extruder at 180-220°C to form a melt; after the melt passes through a ...

Embodiment 6~10

[0129] 1. Materials and sources: as shown in Table 4.

[0130] Table 4:

[0131] use Chemical name / Common name Trade name / source

[0132] thermoplastic elastomer SEPS Septon2063 polyolefin Polypropylene Formalene 1102KR softener white mineral oil Calumet Calsol5550 lubricant Erucamide PMC Kemamide B Powder antioxidant Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester BASF Irganox 1010 antioxidant Tris(2.4-di-tert-butylphenyl)phosphite BASF Irganox 168

[0133] 2. Formulation and performance test: as shown in Table 5. Preparation method: similar to Examples 1-5.

[0134] table 5:

[0135]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com