System for producing POY-FDY compound polyester yarns from melt direct-spinning stock solution and preparation method thereof

A technology of melt direct spinning and polyester yarn, which is applied in the field of spinning, can solve the problems of not realizing the process integration of colored skin-core structure composite polyester yarn, not realizing co-spinning, winding, and not realizing melt direct spinning, etc. Achieve the effect of good clustering, compact structure and soft periphery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

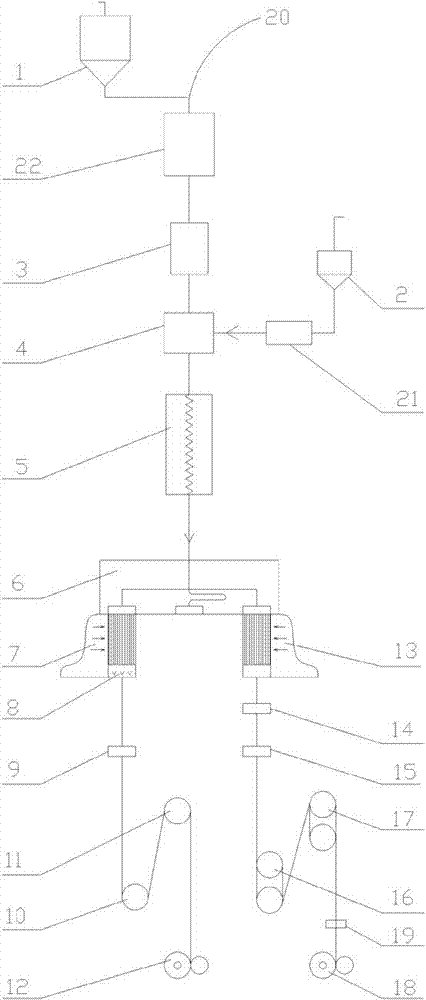

[0032] Embodiment 1: as figure 1 As shown, a system for producing POY and FDY composite polyester yarns from melt direct spinning stock solution includes a PET melt tower 1 and a color paste silo 2, and the PET melt tower 1 communicates with a melt cooler 3, and the The color paste silo 2 and the melt cooler 3 communicate with the multi-element coupler 4 respectively, the multi-element coupler 4 communicates with the dynamic mixer 5, and the dynamic mixer 5 communicates with the spinning beam 6 Through, the described spinning box body 6 communicates with the POY device and the FDY device respectively;

[0033] Described POY device comprises the left blowing cooler 7 that is communicated with spinning box body 6, and described left blowing cooler 7 is provided with spray oiler 8, and described left blowing cooler 7 It communicates with the left pre-networker 9, the left pre-networker 9 communicates with the first godet 10, the first godet 10 communicates with the second godet...

Embodiment 2

[0052] Example 2: In step (1), the thickness of the insulation pipeline is 150mm, the length of the insulation pipeline is 110468mm, the pressure of the booster pump is 13Mpa, the cooling temperature in the melt cooler is 282°C, and the PET melt passes through the melt The cooler time was 2.33 minutes.

Embodiment 3

[0053] Example 3: In step (1), the thickness of the insulation pipe is 160mm, the length of the insulation pipe is 110468mm, the pressure of the booster pump is 13Mpa, the cooling temperature in the melt cooler is 282°C, and the PET melt passes through the melt The cooler time was 2.33 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com