Method and system for concentrating radioactive waste water

A technology of radioactive waste water and concentration tank, which is applied in radioactive purification, nuclear engineering, etc., can solve the problems of high energy consumption, corrosion and scaling, and large amount of radioactive waste resin, and achieve the effect of simple and compact process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

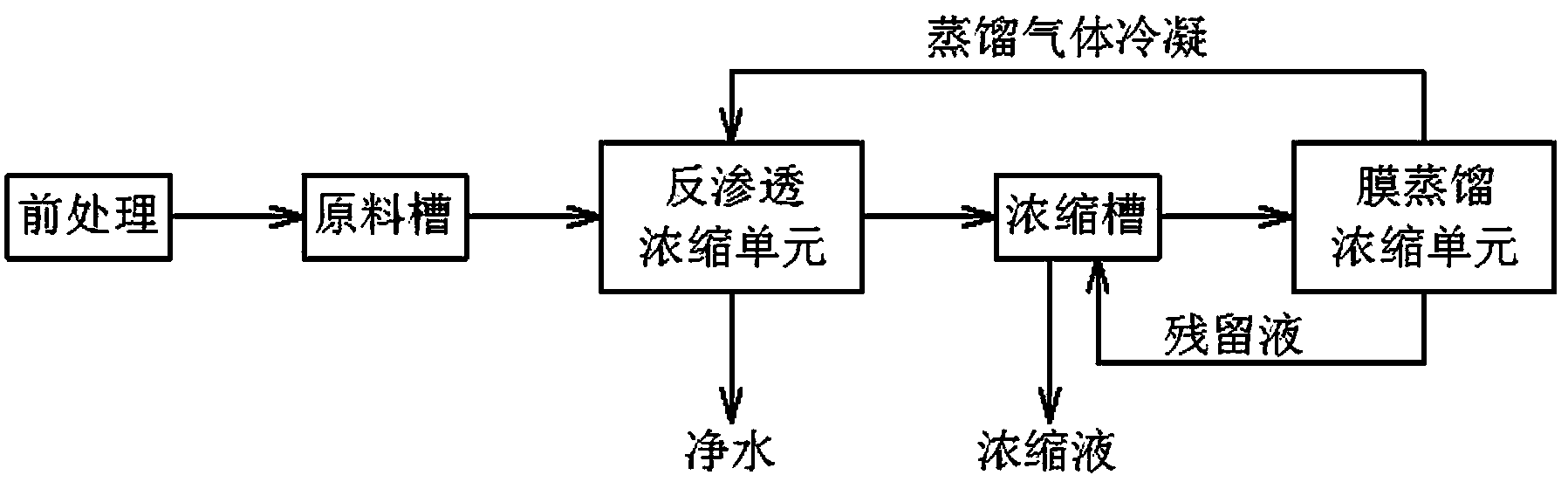

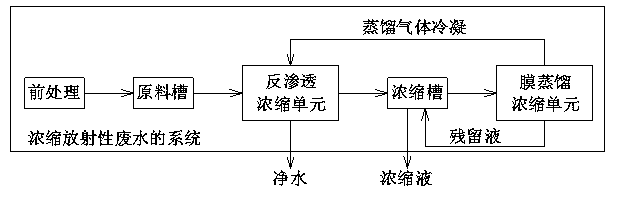

[0041] Such as figure 1 As shown, the concentrated radioactivity level is 7000Bq / L, and the radioactive wastewater concentration method with a salt content of 2g / L.

[0042](1) When the system is started, the membrane modules are automatically flushed with non-radioactive water, and then enter the normal working procedure.

[0043] (2) Pre-treatment of radioactive wastewater: Ultrafiltration removes suspended solids, colloids and other impurities in radioactive wastewater, and the treated radioactive wastewater enters the raw material tank.

[0044] In addition, this process can also use technologies such as microfiltration and sand filtration to remove impurities such as suspended solids and colloids.

[0045] (3) The pre-treated radioactive wastewater is introduced into the reverse osmosis concentration unit for reverse osmosis concentration, the concentrated solution with intercepted radioactive elements is introduced into the concentration tank, and the infiltrated clean ...

Embodiment 2

[0057] The radioactive wastewater treated in this embodiment has a radioactivity level of 5000Bq / L and a salt content of 1g / L.

[0058] Concentration procedure is substantially the same as Example 1, except that:

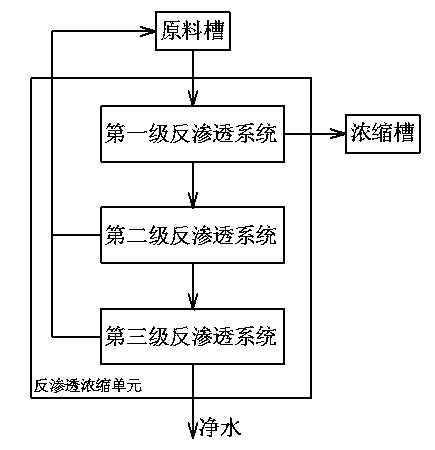

[0059] (1) The reverse osmosis concentration unit adopts a two-stage reverse osmosis membrane system. The first-stage reverse osmosis system is divided into three sections, and the total recovery rate of the reverse osmosis system is 80%. The fresh water radioactivity of the two-stage reverse osmosis system is 150 Bq / L and 50 Bq / L respectively, and the fresh water produced by the last-stage membrane system is discharged. The concentrate produced by the first-stage reverse osmosis system all enters the concentration tank, with a salt content of about 5g / L.

[0060] (2) The heating temperature of the concentrate in the concentration tank is controlled at 55 degrees, and the circulation flow rate of a single membrane module in the membrane distillation concentration u...

Embodiment 3

[0064] The radioactivity level of the radioactive wastewater treated in this embodiment is 3000Bq / L, and the radioactive wastewater with a salt content of 3g / L.

[0065] Concentration process is basically the same as embodiment, difference is:

[0066] (1) The reverse osmosis concentration unit adopts a three-stage reverse osmosis membrane system, the first-stage reverse osmosis system is divided into three sections, and the total recovery rate of the reverse osmosis system is 70%. The fresh water radioactivity of the three-stage reverse osmosis is 100 Bq / L, 50 Bq / L, and 10 Bq / L respectively, and the fresh water produced by the last-stage membrane system is discharged. The concentrate produced by the first-stage reverse osmosis system all enters the concentration tank, with a salt content of about 9g / L.

[0067] (2) The heating temperature of the concentrate in the concentration tank is controlled at 60 degrees, and the circulation flow rate of a single membrane module in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com