Manufacturing method of high-temperature-resistant cables

A high-temperature, cable-resistant technology, applied in cable/conductor manufacturing, insulated cables, cables, etc., can solve problems such as restricting the technological innovation and development of boiler products, failing to achieve rapid and substantial development, affecting the service life of boilers, and reducing maintenance. Frequency and maintenance cost, good chemical and anti-aging performance, and the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: Select a steam boiler with a rated power of 50kw, the ambient temperature is 280°C, the humidity is 90%, and the equipment is continuously operated for 7-8 days; the limit temperature of the high-temperature cable is required to exceed the normal operating ambient temperature by 20°C Above, when the equipment has been running continuously for more than 15 days, there will be no abnormality in the line body, ensuring the normal use of the boiler, and there will be no safety hazards such as line overload and cable overload heating.

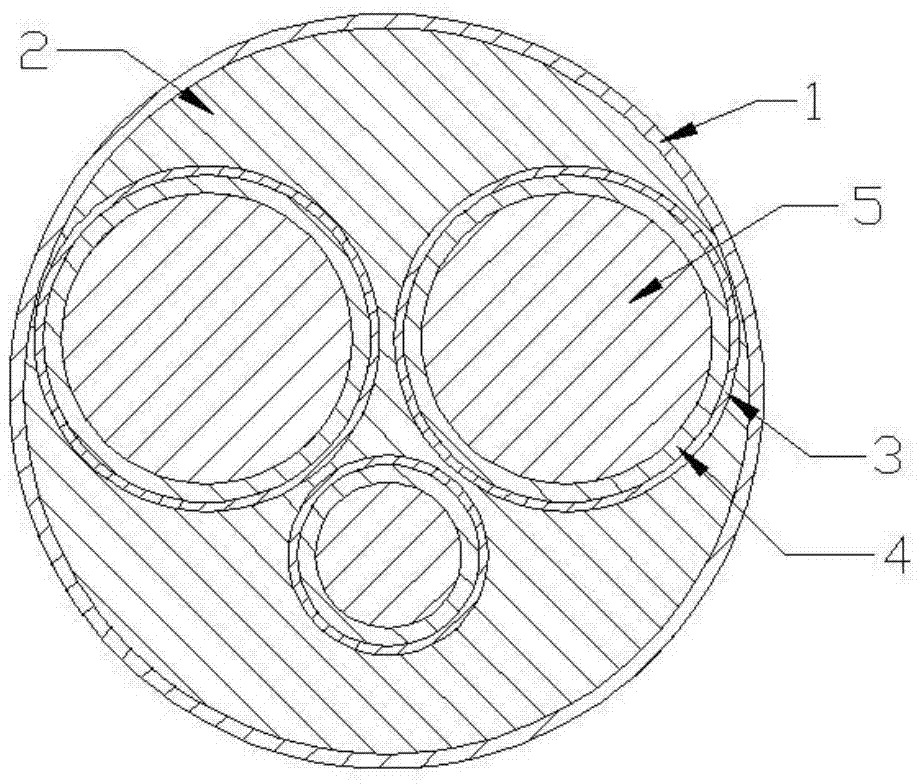

[0013] Using the high-temperature cable prepared in this embodiment, three plugs are used, and the conductor carrying capacity is calculated to select 99.95% pure copper as the material of the positive and negative conductors, with a diameter of 8mm; the ground wire conductor is 99.95% pure copper, with a diameter of 8 mm. 4mm; all internal wires are made of silicone rubber as the conductor insulation material with a thickness of 1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com