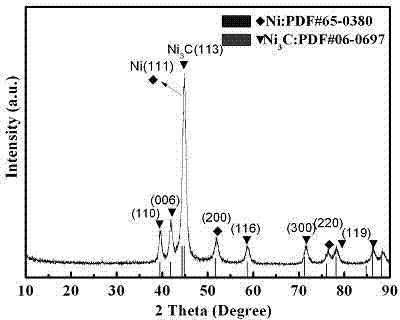

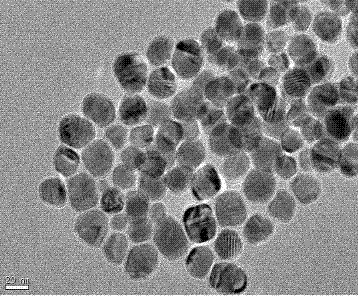

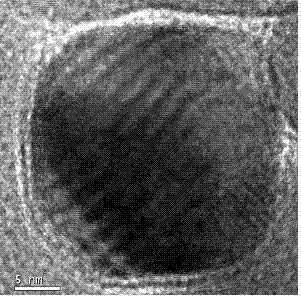

Method for preparing nanometer particles of nickel-carbide nickel core-shell structure

A nanoparticle, core-shell structure technology, applied in the field of preparation of magnetic nanoparticles, can solve the problems of uneven nanochains, thick shell thickness, serious problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 A method for preparing nickel-nickel carbide core-shell nanoparticles, comprising the following steps:

[0034] (1) Mix the nickel precursor compound, octadecene and alkylamine uniformly to obtain the mixed solution A.

[0035] Wherein: the molar volume ratio of nickel precursor compound to octadecene is 0.5mmol:4mL, and the molar volume ratio of nickel precursor compound to alkylamine is 0.5mmol:0.6mL.

[0036] The precursor compound of nickel refers to nickel acetylacetonate.

[0037] Alkylamine refers to cetylamine.

[0038] (2) Stir the mixed solution A with inert gas argon at a flow rate of 40mL / min at room temperature for 10 minutes, then raise the temperature to 120°C, then inject trioctylphosphine into the mixed solution A under the protection of argon, and mix well to form Mixture B, that is, the ligand compound of nickel.

[0039] Wherein: the molar ratio of trioctylphosphine to nickel precursor compound is 1:1.

[0040] (3) After mixing octad...

Embodiment 2

[0047] Example 2 A method for preparing nickel-nickel carbide core-shell nanoparticles, comprising the following steps:

[0048] (1) Mix the nickel precursor compound, octadecene and alkylamine uniformly to obtain the mixed liquid A.

[0049] Wherein: the molar volume ratio of nickel precursor compound to octadecene is 1.5mmol:6mL, and the molar volume ratio of nickel precursor compound to alkylamine is 1.5mmol:1.2mL.

[0050] The precursor compound of nickel refers to nickel acetylacetonate.

[0051] Alkylamine refers to dodecylamine.

[0052] (2) Mixed solution A is stirred at room temperature with inert gas argon at a flow rate of 60mL / min for 20 minutes, then heated to 140°C, and then injected trioctylphosphine into mixed solution A under the protection of argon, and mixed evenly to form Mixture B, that is, the ligand compound of nickel.

[0053] Wherein: the molar ratio of the precursor compound of trioctylphosphine to nickel is 3:1.

[0054] (3) After mixing oct...

Embodiment 3

[0061] Example 3 A method for preparing nickel-nickel carbide core-shell nanoparticles, comprising the following steps:

[0062] (1) Mix the nickel precursor compound, octadecene and alkylamine uniformly to obtain the mixed liquid A.

[0063] Wherein: the molar volume ratio of the nickel precursor compound to octadecene is 1 mmol: 5 mL, and the molar volume ratio of the nickel precursor compound to alkylamine is 1 mmol: 0.9 mL.

[0064] The precursor compound of nickel refers to nickel acetylacetonate.

[0065] Alkylamine refers to oleylamine.

[0066] (2) Stir the mixed solution A with inert gas argon at a flow rate of 50mL / min at room temperature for 15 minutes, then raise the temperature to 130°C, then inject trioctylphosphine into the mixed solution A under the protection of argon, and mix well to form Mixture B, that is, the ligand compound of nickel.

[0067] Wherein: the molar ratio of trioctylphosphine to nickel precursor compound is 2:1.

[0068] (3) After mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com