Preparation method of H-ZSM (Zeolite Socony Mobil)-20 molecular sieve

A molecular sieve, 18-crown-6 technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of no breakthrough in the improvement of ZSM-20 preparation method, harsh conditions, poor reproducibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

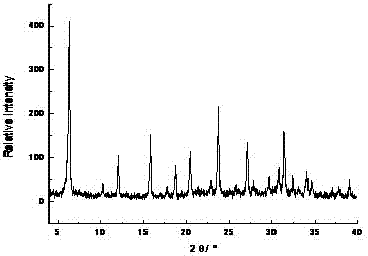

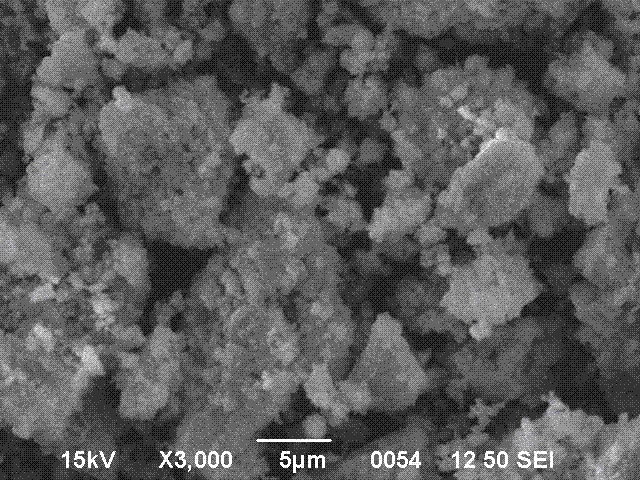

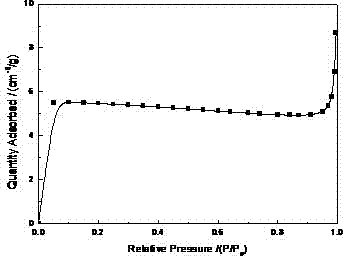

[0018] Weigh 1.74 g of sodium hydroxide, 0.84 g of sodium fluoride, 5.3 g of sodium metaaluminate and 30.74 g of water, add them to a 50 ml polytetrafluoroethylene beaker, and stir magnetically for 10 min to obtain solution A; Add 30.04 g of sol dropwise to solution A, stir thoroughly for 30 min, then slowly add 2.00 g of 15-crown-5 ether and 2.00 g of 18-crown-6 ether dropwise to obtain an emulsion, continue stirring for 3 h, and let it stand at room temperature Stand for 24 h; then transfer the above emulsion to a polytetrafluoroethylene hydrothermal synthesis reaction kettle, seal it and place it in an oven, and crystallize at 110 °C for 15 days; cool, wash until neutral, and filter the obtained solid in Dry at 100°C for 12 h, grind the dried solid, and then calcinate at 550°C for 6 h by temperature programming to obtain white powder molecular sieve ZSM-20. Its relative crystallinity is 85.3%.

Embodiment 2

[0020] Repeat Example 1, but change the added silica sol to 39.18g, 52.24g, and 65.31g respectively, and only use 39.18g of silica sol to obtain the product crystal as ZSM-20, and its relative crystallinity is 93.1%.

Embodiment 3

[0022] Repeat Example 1, but change the added 15-crown-5 ether and 18-crown-6 ether to 1.94g and 2.32g, 1.65g and 2.40g respectively, only the crystal phase of the product obtained by the former is ZSM-20, Their relative crystallinity was 74.1%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com