Preparation method of particle size controllable cuprous oxide micro-spheres

A cuprous oxide and microsphere technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of large number of surfactants, doubts about safety impact, limited control range, etc., and achieve low prices, less environmental pollution, and reagents. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

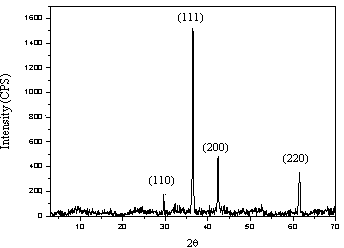

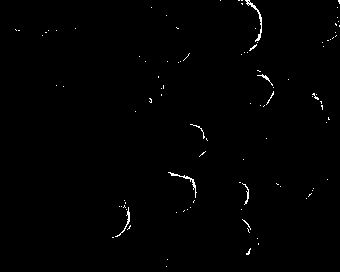

Image

Examples

Embodiment 1

[0016] (1) Prepare 50 ml of an aqueous solution containing citric acid and calcium hydroxide, the concentrations of which are 0.095 mol per liter and 0.68 mol per liter, respectively, and stir to obtain a uniform suspension, then the aqueous solution containing 0.44 mol per liter of phosphoric acid is added one by one. Add dropwise, stop dropping when the pH value of the suspension drops to 10, wash with 50 ml of ammonium chloride solution with a mass fraction of 4% after standing for 18 hours, and prepare the hydroxyapatite colloid obtained by centrifugation into 100. ml of aqueous solution;

[0017] (2) adding copper sulfate to the hydroxyapatite colloidal solution prepared in step (1) to make the initial concentration of copper ions be 0.10 moles per liter, and stirring for 12 hours;

[0018] (3) Glucose, sodium carbonate and trisodium citrate were sequentially added to the solution prepared in step (2), the concentrations were 0.36, 0.11 and 0.016 mol per liter, respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com