Method for producing tetramethylethylene by using isobutene

A technology of tetramethylethylene and isobutylene, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problem of low weight yield of tetramethylethylene, and achieve increased weight yield and improved selectivity and the effect of improving the yield and disproportionation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 1 kg of silica gel and 10 grams of scallop powder into the blender and stir for 45 minutes. After kneading evenly, add 400 grams of silica sol and 113 grams of ammonium metatungstate. At the same time, add 1 kg of deionized water, knead, squeeze, dry, and then Calcined at 550°C for 4 hours to obtain a pale yellow finished disproportionation catalyst with a tungsten oxide content of 8%.

[0019] Add 50 grams of magnesium oxide into deionized water to obtain 300 grams of solution, heat and stir the solution in a water bath at 80°C for 5 hours, then filter the water in the solution with suction, dry the product at 120°C for 6 hours, and roast at 550°C for 6 hours to obtain Finished magnesium oxide.

[0020] Magnesium oxide and 8%WO in the process of catalyst loading 3 / SiO 2 The weight ratio is 4. The operating conditions of the reactor are: the reaction temperature is 380°C, the absolute pressure is 0.1MPa, and the weight space velocity of isobutylene is 1 hour -1...

Embodiment 2~6

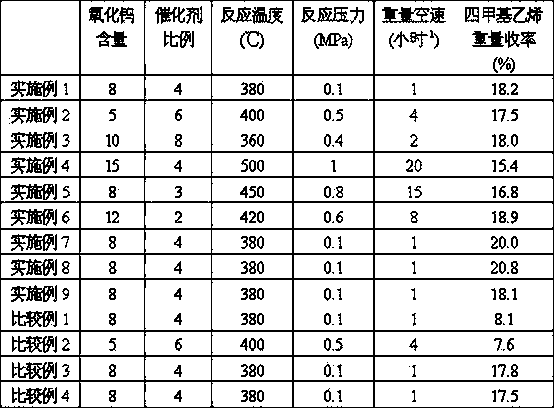

[0023] React by each condition and step of [Example 1], just change different operating parameters, and the results are listed in Table 1.

[0024]

Embodiment 7

[0026] React by each condition and step of [embodiment 1], just add 137.6 gram zirconium nitrates when adding 50 gram magnesium oxides. The weight ratio of magnesium oxide to zirconium oxide in the prepared catalyst was 1:1, the evaluation conditions were the same as in Example 1, and the reaction results are shown in Table 1.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com