Method for improving anaerobic methanogenesis efficiency by using nano magnetite

An anaerobic methane production and nano-magnet technology, which is applied in waste fuel, fermentation and other directions, can solve the problems of increasing the operating cost of biogas projects, long biogas fermentation period, limiting the rate of biogas fermentation process, etc., so as to improve energy utilization efficiency and improve methane effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Synthesize 10nm magnetite colloidal solution by co-precipitation method according to the prior art, and set it aside. Anaerobic digested sludge was selected as the inoculum, and the electron donor was a mixture of propionic acid and butyric acid (mass ratio, 1:1).

[0022] Add the above-mentioned magnetite with a final concentration of 2g / L, anaerobic digested sludge with a final concentration of 15g / L, propionic acid and butyric acid (5g / L each), and 150mL of medium In the anaerobic reactor with residual oxygen in the bottle, it is anaerobically fermented under the sealed conditions of pH=7.0 and 37°C.

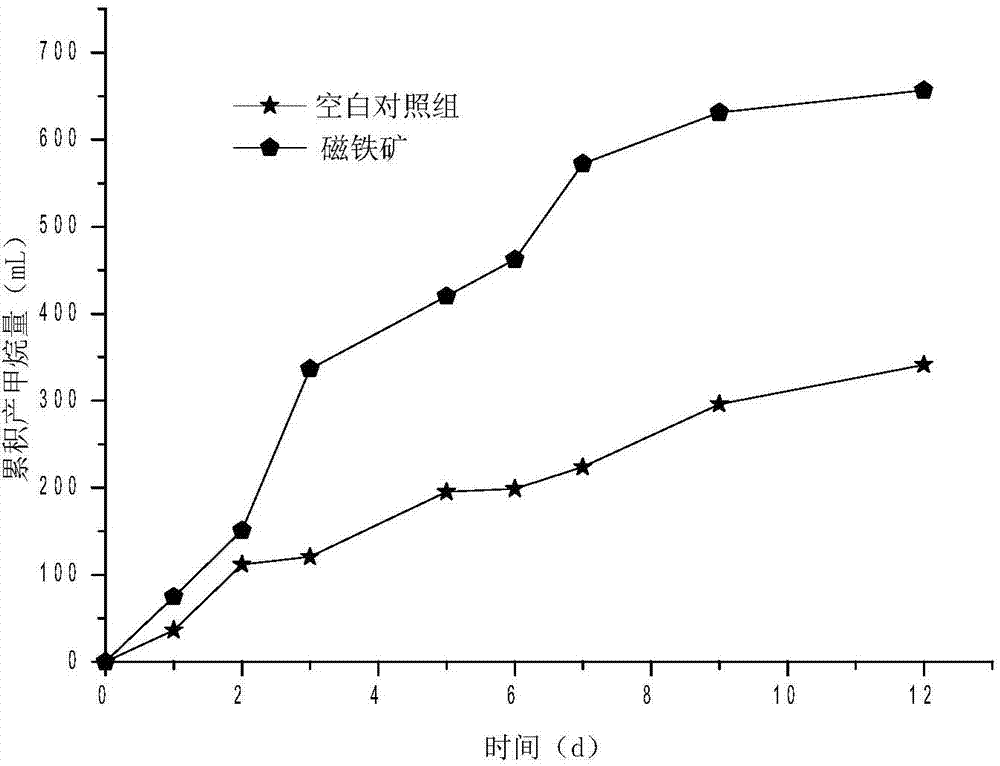

[0023] At the same time, no magnetite was added as a control group (see figure 1 ).

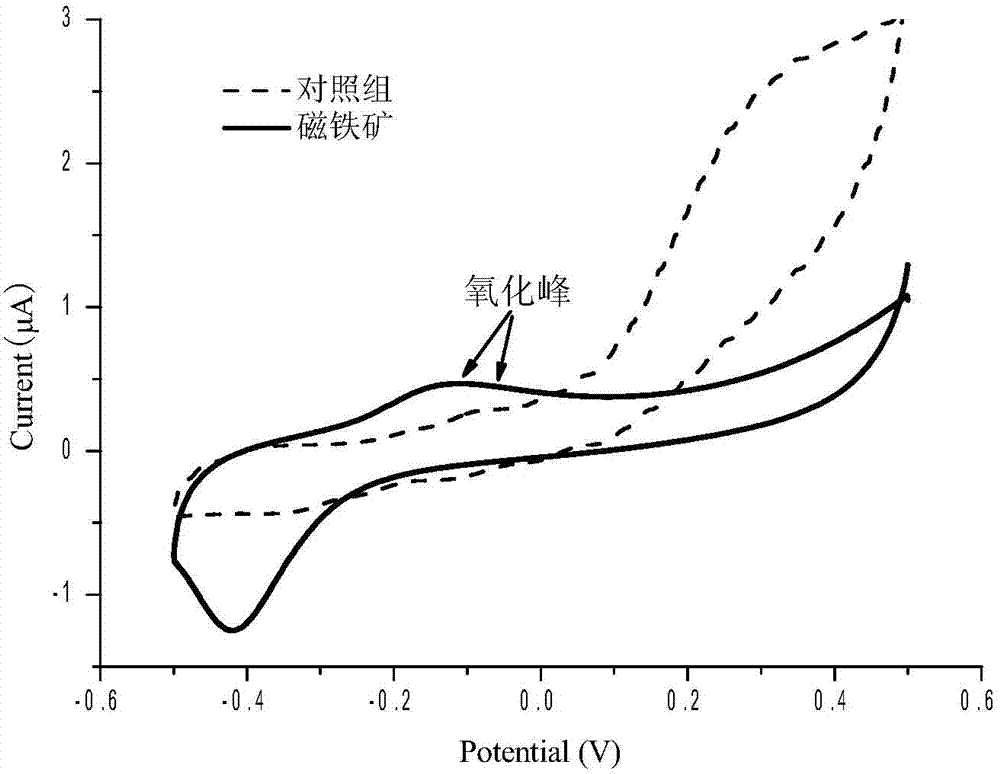

[0024] Depend on figure 1 It was shown that the addition of magnetite led to a 90% increase in methane production and a 1.9-fold increase in methane production rate compared with the group without magnetite addition, and the enriched mutualistic microbial flora had significant elec...

Embodiment 2

[0029] Synthesize 10nm magnetite colloidal solution by co-precipitation method according to the prior art, and set it aside. Paddy soil was selected as the inoculum, and the electron donor was propionic acid.

[0030] Add the above-mentioned magnetite with a final concentration of 2g / L, paddy soil with a final concentration of 10g / L, propionic acid (5g / L) and medium (30mL) into the anaerobic bottle purged with high-purity nitrogen to remove residual oxygen In the anaerobic reactor, the anaerobic fermentation was carried out under the sealed conditions of pH=7.0 and 37°C.

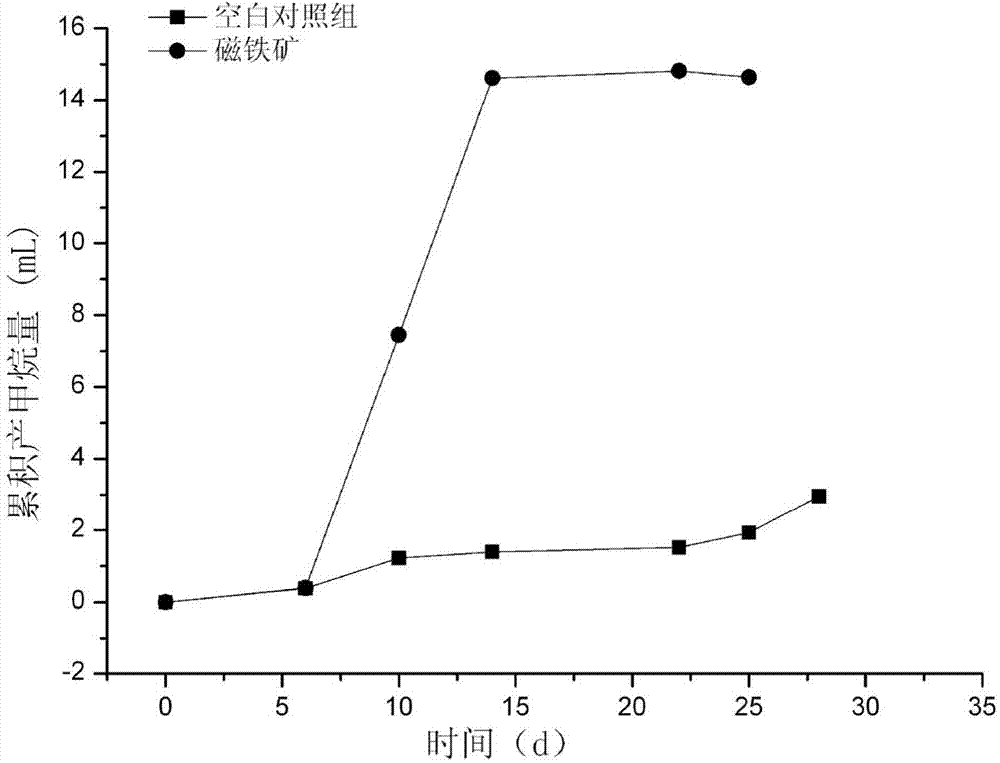

[0031] At the same time, no magnetite was added as a control group (see image 3 ).

[0032] Depend on image 3 It was shown that the addition of magnetite led to a 7-fold increase in methane production and a 12-fold increase in the methane generation rate compared to the group without magnetite addition.

[0033] Properties of paddy soil: pH6.3, organic matter 20.1g / kg.

Embodiment 4

[0035] Synthesize a 30nm magnetite colloidal solution by co-precipitation method according to the prior art, and set it aside. Paddy soil was selected as the inoculum, and the electron donor was butyric acid.

[0036] Add the above-mentioned substances into the culture medium, and then transfer to the anaerobic reactor that purged with high-purity nitrogen to remove the residual oxygen in the anaerobic bottle. Add 8g of butyric acid and 3g of magnetic Iron Ore and 20g of Paddy Soil. Anaerobic fermentation was carried out in a reactor under sealed conditions of pH=7.0 and 37°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com