Ti(C,N)-based metal ceramic and its application

A cermet and base metal technology, applied in the field of Ti-based cermet, can solve the problems of high preparation cost and inability to prepare, and achieve the effects of low raw material cost, low market price and good red hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below through examples.

[0014] The Ti(C,N)-based cermet of the present invention is composed of a ceramic phase and a binding phase.

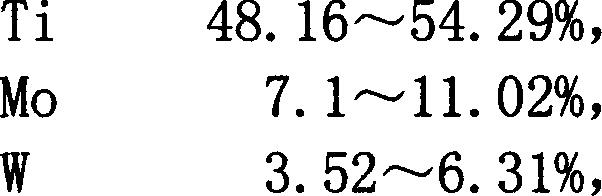

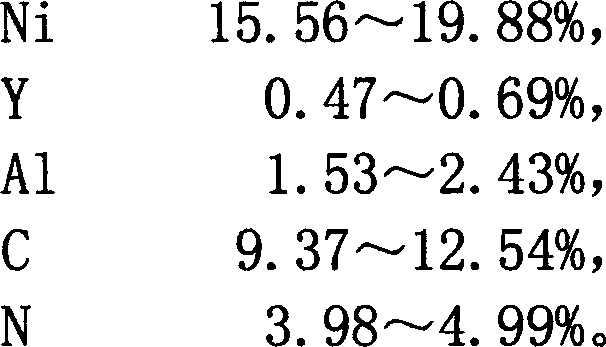

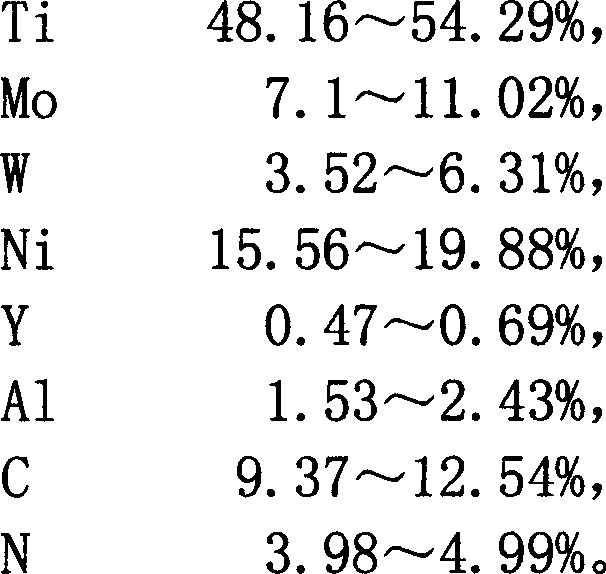

[0015] As shown in Table 1, the mass percentages of the constituent elements in the cermets in different embodiments are:

[0016] The mass percent (wt %) of each constituent element in table 1 cermet

[0017] serial number Ti Mo W Ni Y Al C N 1 48.16 9.88 4.27 19.32 0.63 1.86 11.86 4.02 2 54.15 7.1 3.52 19.88 0.47 1.53 9.37 3.98 3 54.29 11.02 3.52 15.56 0.47 1.53 9.63 3.98 4 50.38 7.1 6.31 15.56 0.69 2.43 12.54 4.99 5 51.26 9 4.69 17 0.6 1.97 11.06 4.42

[0018] The invention also includes the application of Ti(C,N)-based cermets in cutting tools. The milling cutter of the cermet production specification 4160511 described in the present invention is used to process 30CrMo alloy steel, and the above mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com