Method for fabricating high-temperature preheating aluminum oxide progressive-blanking system by using foamed aluminum material

A technology of alumina and foamed aluminum, which is applied in the field of high-temperature preheated alumina continuous blanking system made of foamed aluminum, can solve problems affecting alumina preheating, complex structure, and unproposed problems, and achieve excellent cost performance, large interference, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

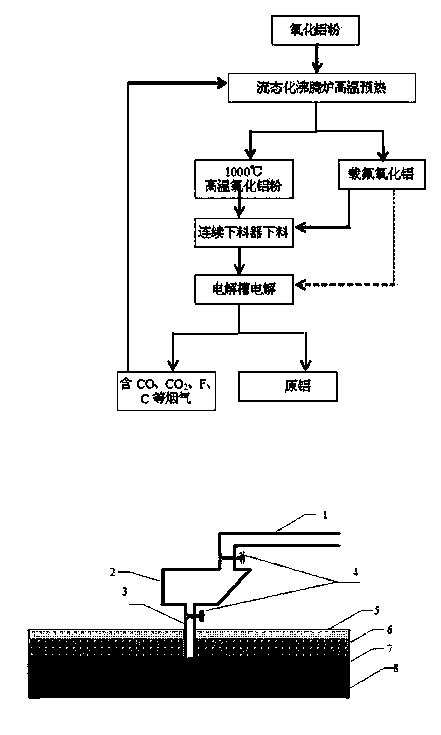

[0012] specific implementation plan

[0013] A company uses 240KA prebaked electrolytic cells to produce metal aluminum, with a designed production capacity of 110,000 tons of primary aluminum per year, 171 electrolytic cells, a single cell with a daily output of 1618.5kg of primary aluminum, a single cell with an annual output of 663 tons, and a daily aluminum oxide consumption of 1,930 tons of aluminum. kg, the annual consumption of alumina is 207,000 tons. The alumina transportation system is as follows: from the company's alumina warehouse to the 800-ton intermediate silo near the electrolysis workshop (about 1.4 times the daily consumption); from the silo to the Each electrolyzer material box adopts super-dense phase conveying. The feeding of the electrolytic tank adopts fixed-point feeding, the blanking time is 89 seconds, and the feeding volume is about 3.6kg. Each electrolytic tank is equipped with 4 shelling and feeding cylinders, and the feeding is crossed in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com