Overlay error measurement apparatus and method

An overlay error and measuring device technology, which is applied in the field of equipment in the field of integrated circuit manufacturing, can solve the problems of limited wavelength range of measurement light, reduced information volume, small focal depth range, etc., achieve good process adaptability, reduce control difficulty, Measuring a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

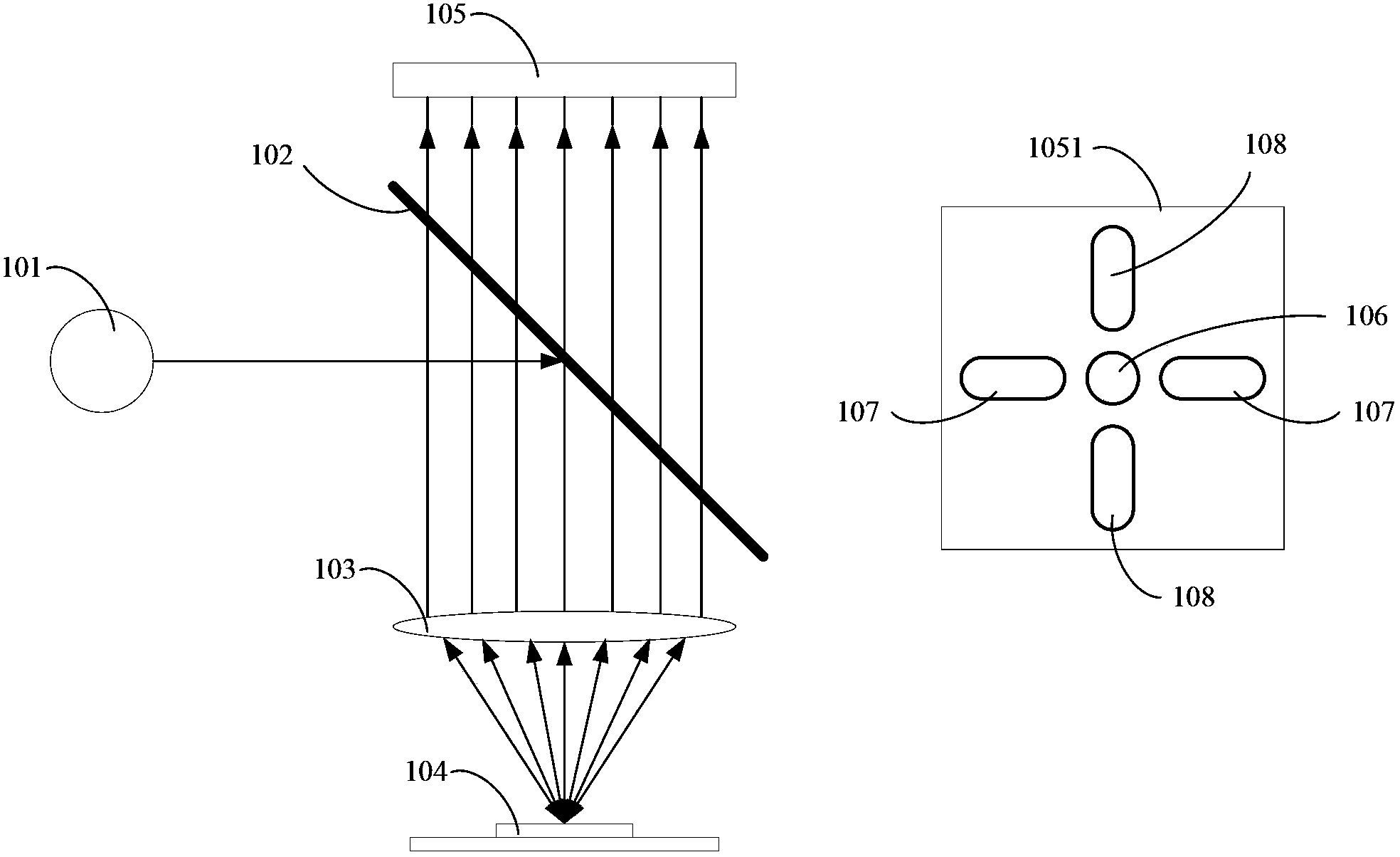

[0059] The present invention provides an overlay error measuring device, please refer to figure 1 ,include:

[0060] The broadband light source 101 is used to generate a wide-band measuring light beam. The wavelength bands of the broadband light source include visible light, ultraviolet and infrared. The broadband light source 101 can be one of a xenon lamp, a deuterium lamp and a halogen lamp or A variety of combinations, so that it can have a wider range of wavelength selection, while in the prior art, several discrete wavelengths in the visible light band are used as measurement light, and the wavelength range and selectivity are greatly limited;

[0061] A beam splitter 102, the beam splitter 102 is located on the optical path of the measurement beam emitted by the broadband light source 101, so that the measurement beam is refracted;

[0062] An objective lens 103, the objective lens 103 receives and converges the deflected measuring beam so that it is incident on the ov...

Embodiment 2

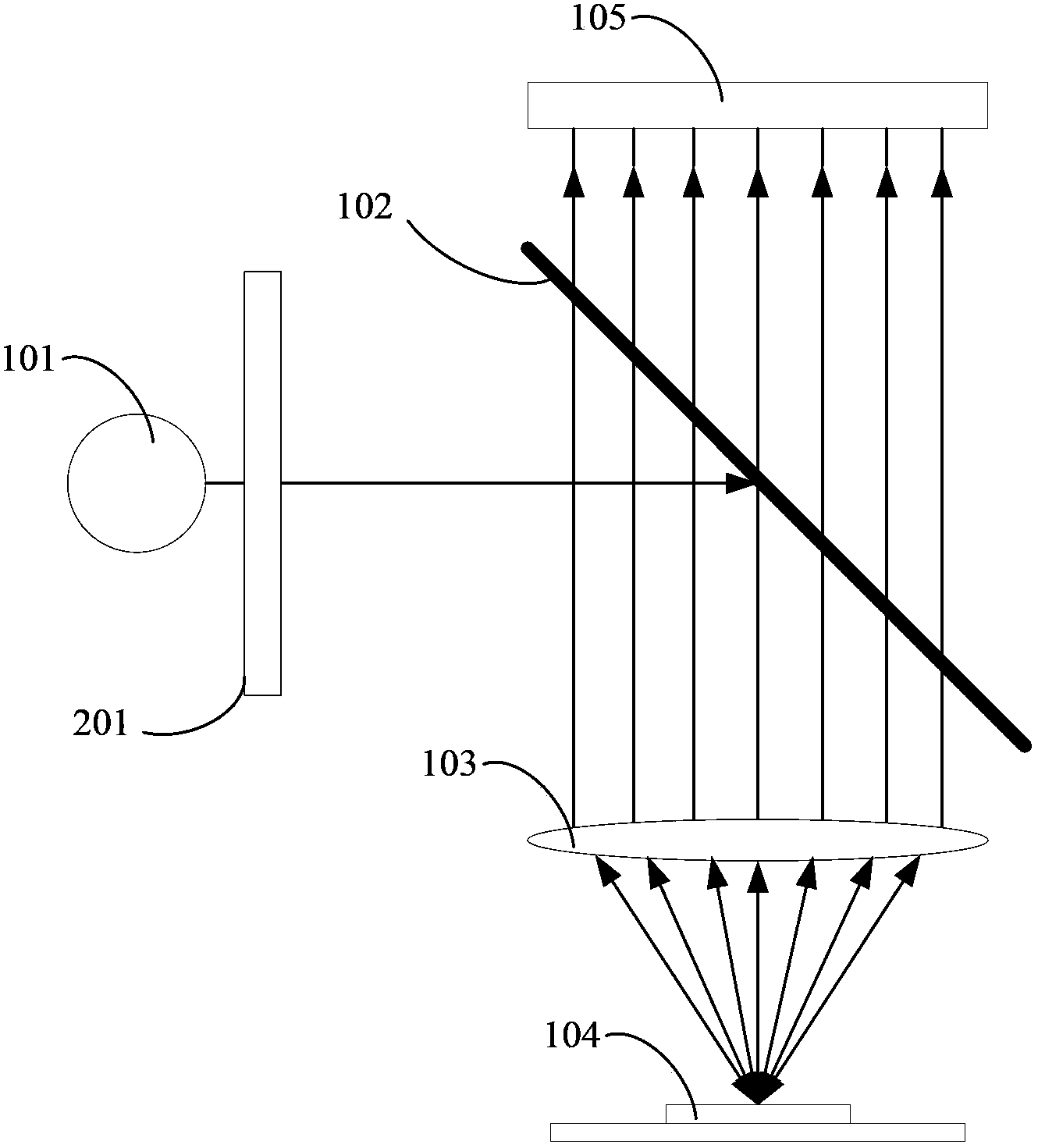

[0065] Please refer to figure 2 , in order to further improve the process adaptability and measurement accuracy of the measuring device, a polarizer 201 can be added on the basis of Embodiment 1, and the polarizer 201 can generate a polarized measurement beam. Specifically, the polarized measurement beam can be The polarization measurement beam of the TE mode may also be the polarization measurement beam of the TM mode. In different semiconductor manufacturing processes, there are certain differences in the sensitivity of different polarized lights to overlay errors. Therefore, for specific overlay measurement marks, the polarization direction with higher sensitivity can be selected for measurement to further improve process adaptability .

Embodiment 3

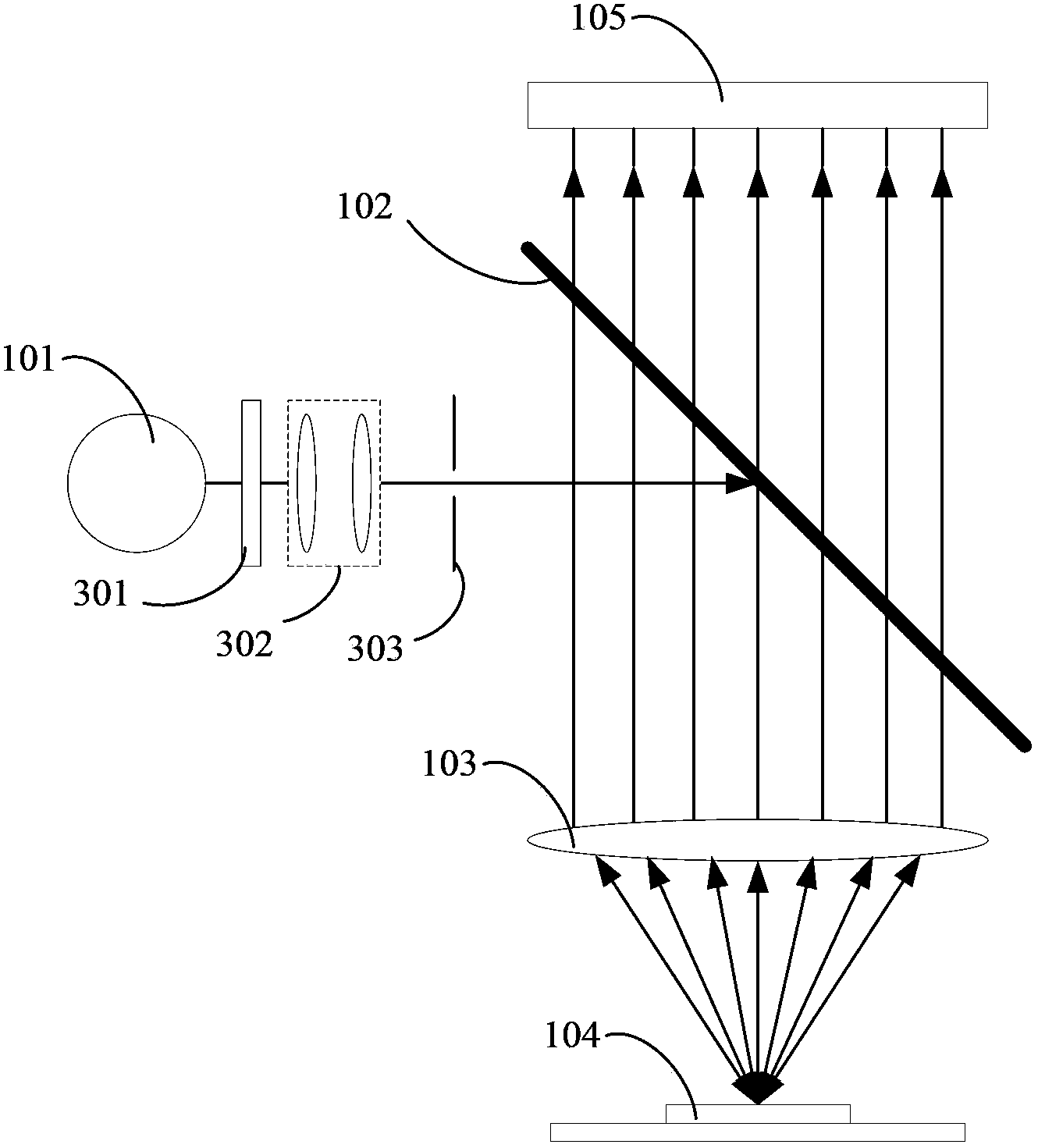

[0067] It is known that the spatial frequency of each order of diffracted light is sinθ=nλ / p, where θ is the diffraction angle, n is the diffraction order, λ is the wavelength, and p is the overlay measurement mark period. Since the measurement uses a broadband light source, within the same diffraction order, the diffracted light of each wavelength is spatially separated. In this embodiment, the overlay error is determined by measuring the light intensity asymmetry of the diffracted light of the same wavelength. Therefore, it is necessary to accurately determine the position of the diffracted light of the same wavelength on the first detector. In this embodiment, as image 3 The scheme realizes the calibration of the diffraction spectrum position: after the broadband light source 101, a filter device 301 is added, and the filter device 301 can filter out one or more wavelengths, that is, generate one or more monochromatic lights, which will be One or more separated diffractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com