Near ultraviolet or ultraviolet excited LED light-emitting device

A light-emitting device, near-ultraviolet technology, applied in the direction of light-emitting materials, electrical components, electrical solid devices, etc., can solve the problems of light decay, low color rendering index of packaged products, narrow half-wave width of emission spectrum, etc., and achieve high energy conversion efficiency. , the effect of good color temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] like Figure 5 As shown, the white light emitting device of this embodiment belongs to the SMD package, including the packaging substrate 3, the LED chip 1 and two electrodes 2, and the two electrodes are respectively at both ends of the packaging substrate 3, and are used to lead out the positive and negative electrodes of the LED chip 1. pole.

[0052] First, the chip 1 is fixed on the package substrate 3 , and the two ends of the chip are respectively connected to the two pole pieces at the bottom of the substrate through gold wires so as to conduct with the two electrodes 2 .

[0053] Then, formulate according to a certain ratio (when the particle size of phosphor powder changes, the ratio needs to be adjusted. In fact, the particle size of each batch of phosphor powder is not exactly the same, so when making LEDs, every time you purchase one Batches of phosphors need to be adjusted once. Also, when the color temperature of the packaged white LEDs is different, the...

Embodiment 2

[0063] like Image 6 As shown, the white light emitting device of this embodiment belongs to an integrated package, including a package substrate 1, an LED chip 2, and two electrodes 3. pole.

[0064] First, a number of chips 2 are fixed on the packaging substrate 1, and the two ends of the chips are respectively connected to the two pole pieces at the bottom of the substrate through gold wires in a series-parallel manner, so as to conduct with the two electrodes 3 .

[0065] Next, after damming and baking, a mixed colloid containing red, green and blue phosphors is formulated in a certain proportion, stirred evenly, and vacuum defoamed.

[0066] Further, the mixed colloid is evenly coated on the LED chip, and the coating thickness is set reasonably to ensure good light color uniformity, so that the LED maintains a high light extraction efficiency without light spots.

[0067] The advantage of integrated packaging is that multiple chips can be arranged on a smaller substrate...

Embodiment 3

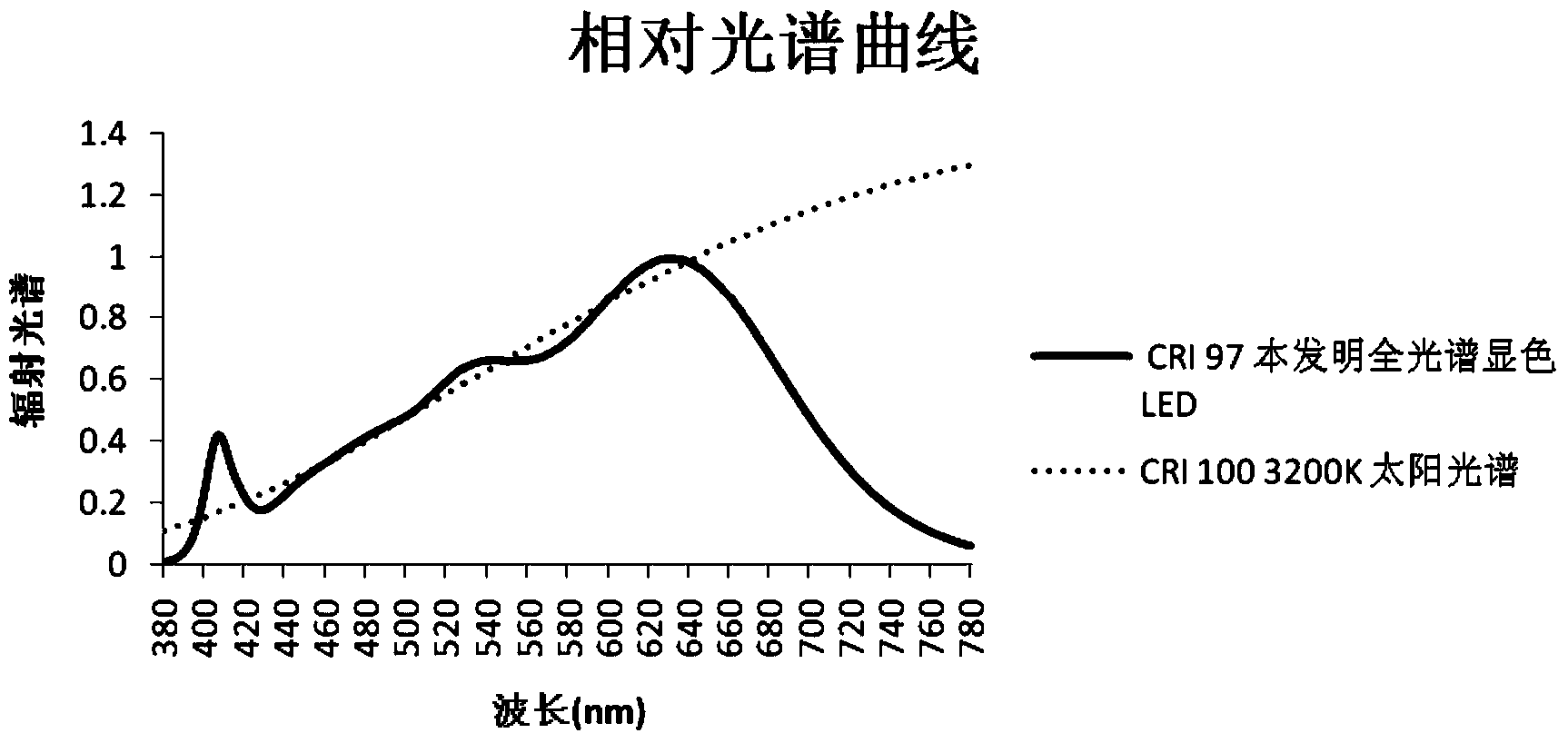

[0069] Load the optical filter on the chip of Example 1.

[0070] Its mixed spectrum is as Figure 4 shown.

[0071] After the filter is added, the possible leakage of ultraviolet light is eliminated to harm the human body. On the other hand, the eliminated peak of the purple light emitted by the purple light chip makes the spectral shape of the entire white light LED device closer to the solar spectrum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com