A kind of production device of magnesium alloy fiber wire

A production device and technology of fiber filaments, applied in the field of metal fiber filament production devices, can solve problems such as high cost, limited application, and influence on the use effect, and achieve the effects of stable quality, easy operation, and good length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described below with reference to the accompanying drawings. It should be understood that the detailed structure of the magnesium alloy fiber filament production device of the present invention is not limited to the following examples.

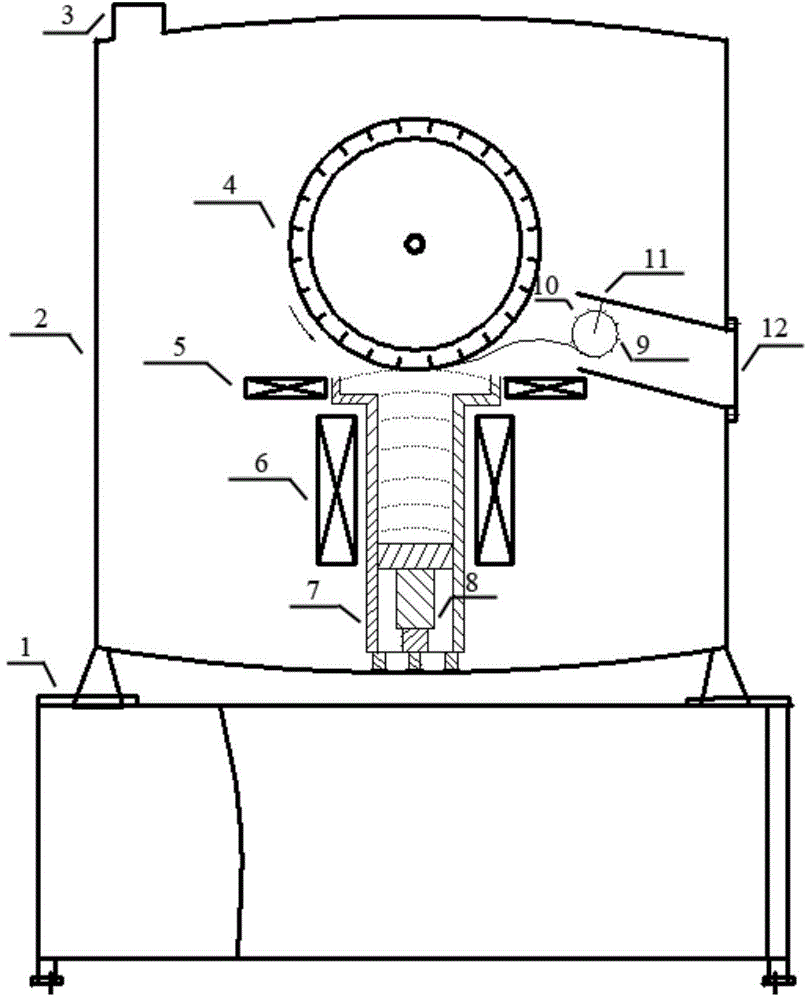

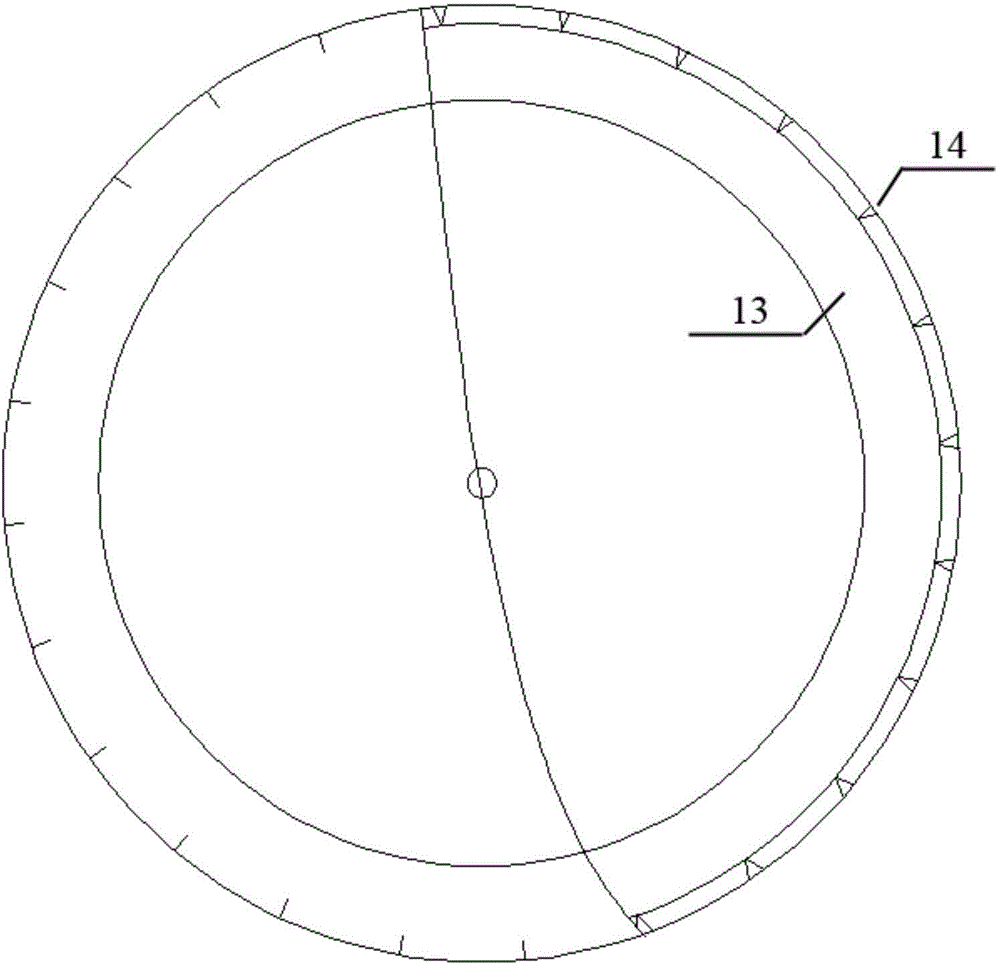

[0016] in the attached figure 1 In the schematic diagram of the magnesium alloy fiber filament production device shown, the vacuum furnace body 2 is fixed on the base 1, the vacuum valve 3 is arranged above the furnace body, and the spinning wheel 4 is arranged at the center of the furnace body, as shown in FIG. figure 2 As shown, the material used for the spinning wheel is alumina dispersion strengthened copper, and the inner cavity is filled with high-pressure cold water 13 as a medium, and a number of equidistant V-shaped grooves 14 are arranged on the outer edge of the wheel along the direction of the generatrix of the wheel. , and the chute equal to the number of V-shaped grooves is provided on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com