Preparation method for needle point type silicon nanowire

A silicon nanowire and needle-tip technology, which is applied in the field of preparation of needle-point silicon nanowires, can solve the problems of incapable of large-scale industrial production, general poor adaptability of the method, disordered nanowires, etc., and achieves the convenience of large-scale industrial production and good chemical stability sex, method and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

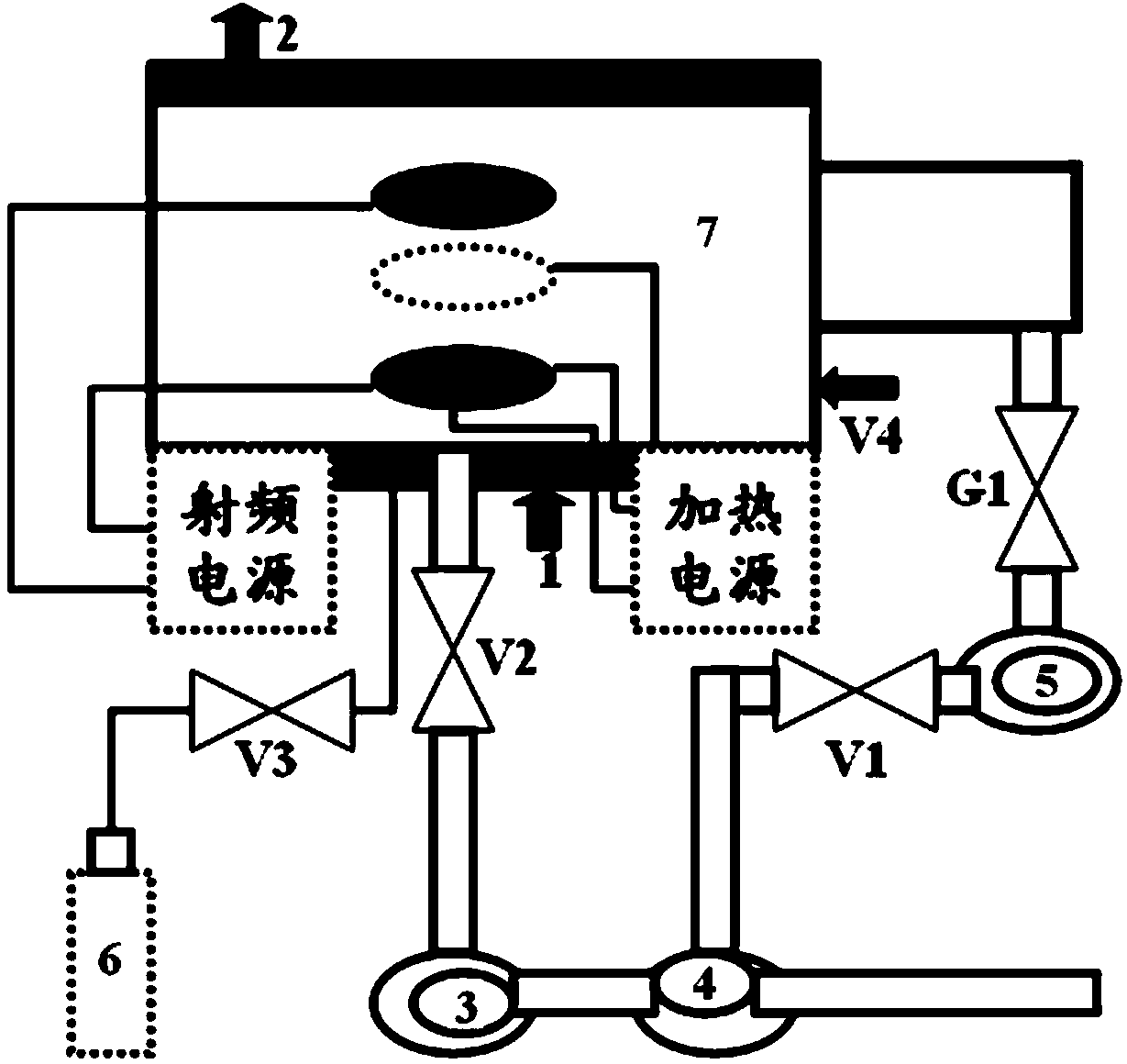

[0035] The invention provides a method for preparing acicular silicon nanowires by using plasma enhanced chemical vapor deposition (PECVD) technology and using silane as a reaction precursor.

[0036] The invention adopts the most suitable gas-liquid-solid mechanism for growing nanowires, reduces the reaction temperature through plasma enhancement, and increases the growth speed of nanowires. The Au film is deposited on the substrate by ion sputtering, and the shape of the needle-shaped nanowires is controlled by the consumption and size change of the alloy droplets after annealing. This method has high reliability, is convenient for industrial production, and can effectively control the needle tip of silicon nanowires. growth.

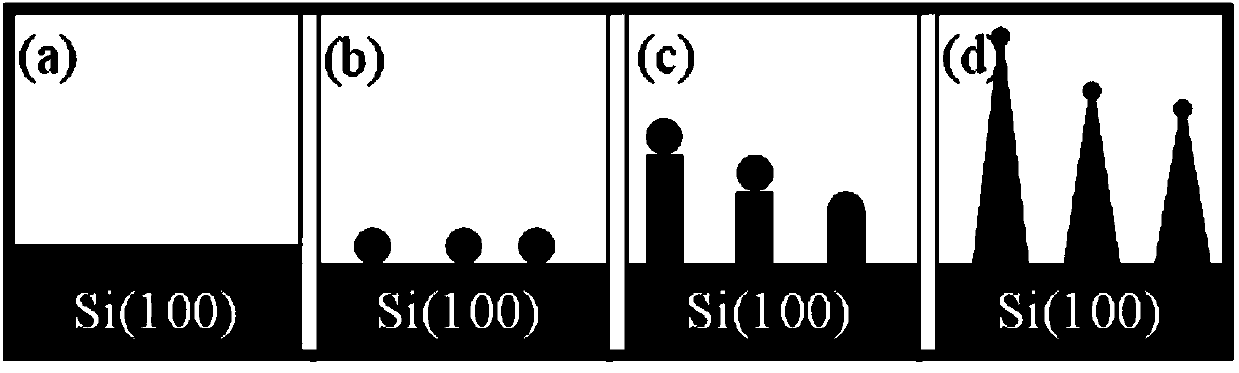

[0037] see figure 2 , the Au film deposited by sputtering on the silicon substrate in the present invention will form go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com