Acid mine waste water treating device

A mine wastewater and acidic technology, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult control of effluent quality, secondary pollution by alkaline method, and poor tolerance of heavy metal ions To achieve the effect of increasing the soluble COD content and mass transfer rate, reducing the concentration of heavy metal ions, and controlling the hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

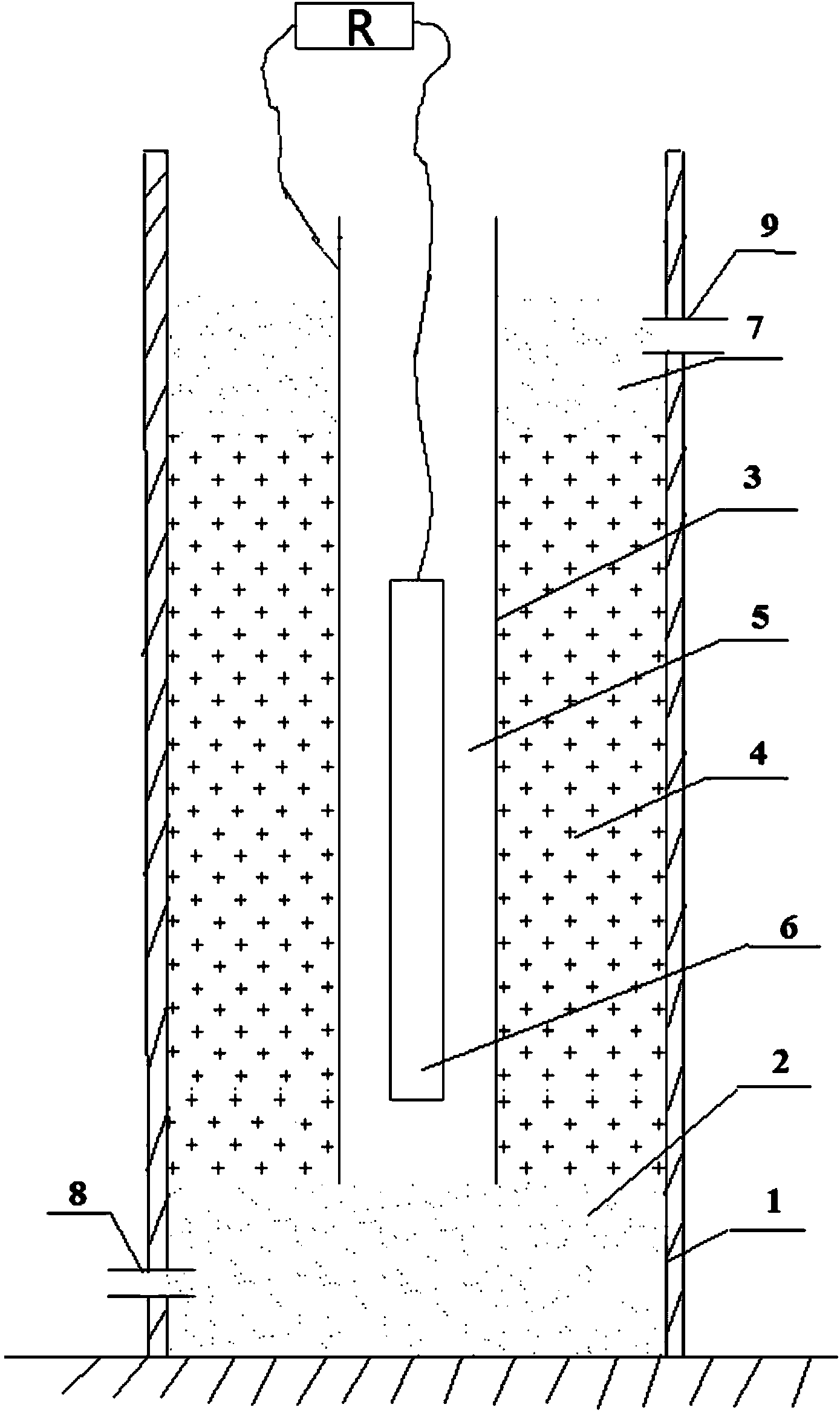

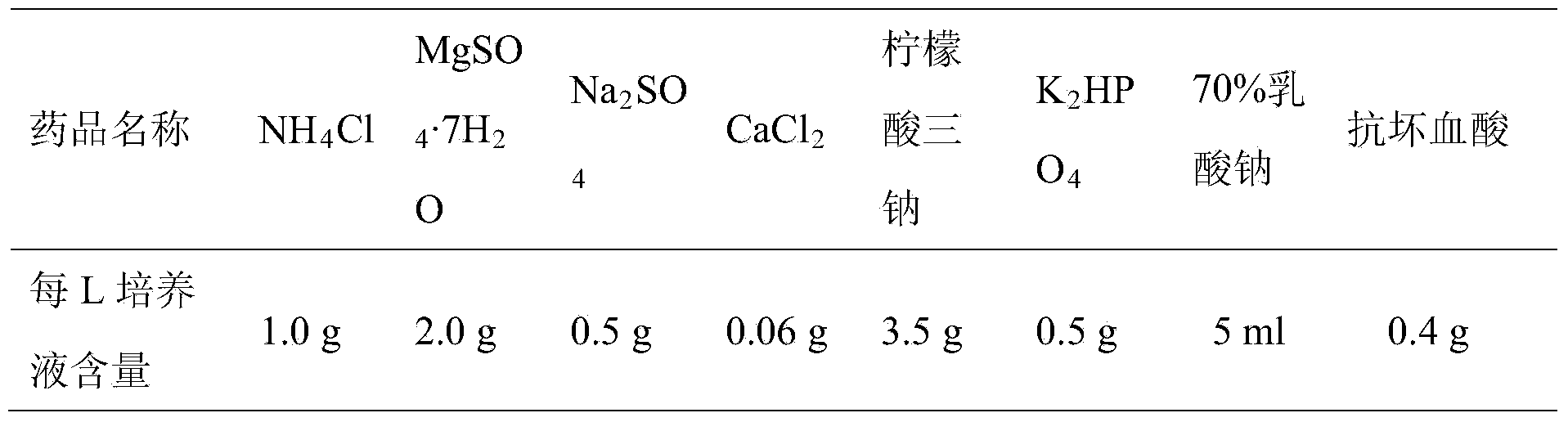

[0014] The permeable reaction well system simulated in the laboratory includes a cylindrical plexiglass tube 1, a mixed packing 4, a microbial fuel cell system and a peristaltic pump. Because the permeability coefficient of rock mass and dam body is much smaller than that of the mixed packing reaction bed, the columnar plexiglass tube 1 is used to simulate instead of the perforated columnar reaction well wall of the rock mass. The reaction well is divided into lower, middle and upper sections: the lower section is the water inlet area, where a fine ceramsite layer 2 with a thickness of 8 cm and a particle size of 1 to 2 mm is laid. A water inlet 8 is set on the pipe wall at the middle height of the fine ceramsite layer to simulate water collection. layer, which plays the role of water distribution and buffering at the same time. The middle section is 50cm high, which is an anaerobic biochemical reaction and microbial fuel cell area, arranged in a concentric circle structure: p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com