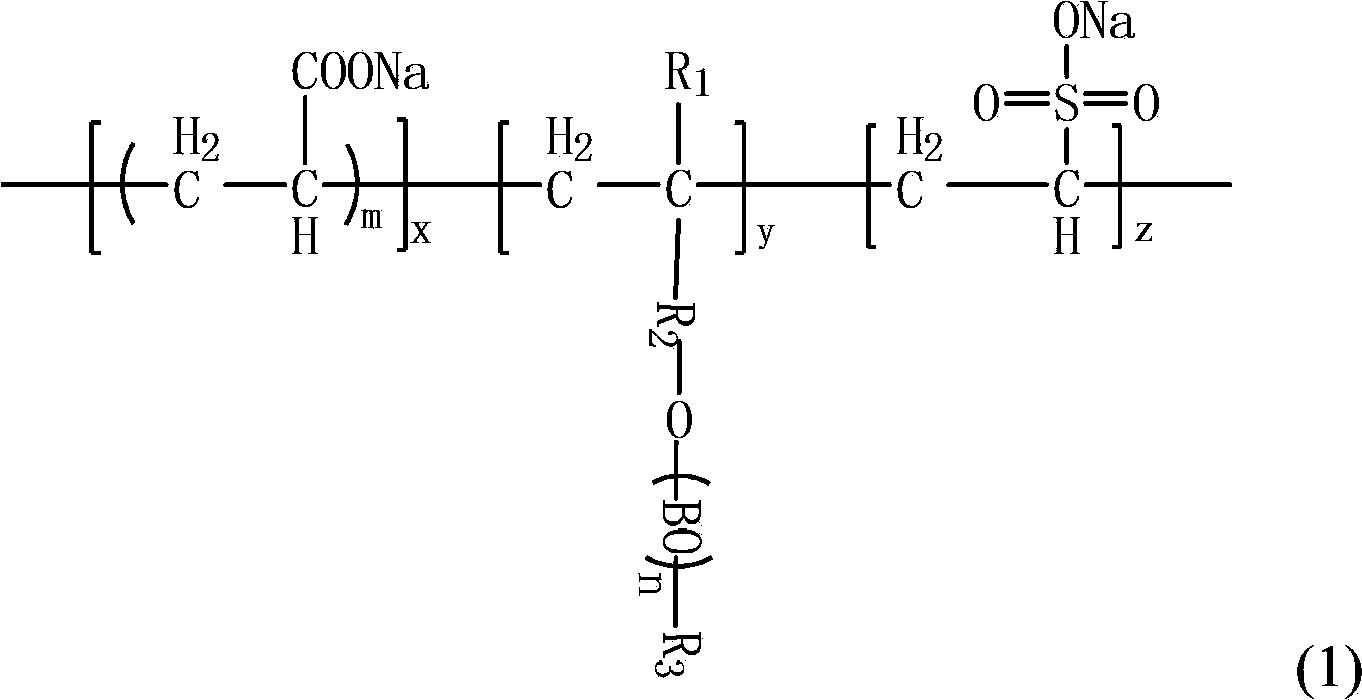

Polycarboxylic acid water reducer used for high mud concrete and synthetic method

A technology of concrete and polycarboxylic acid, which is applied in the field of polycarboxylate water reducer and its preparation, can solve the problems of poor concrete construction performance, poor carbonation resistance, and difficult construction, so as to improve mechanical properties and construction performance, Improved adaptability and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

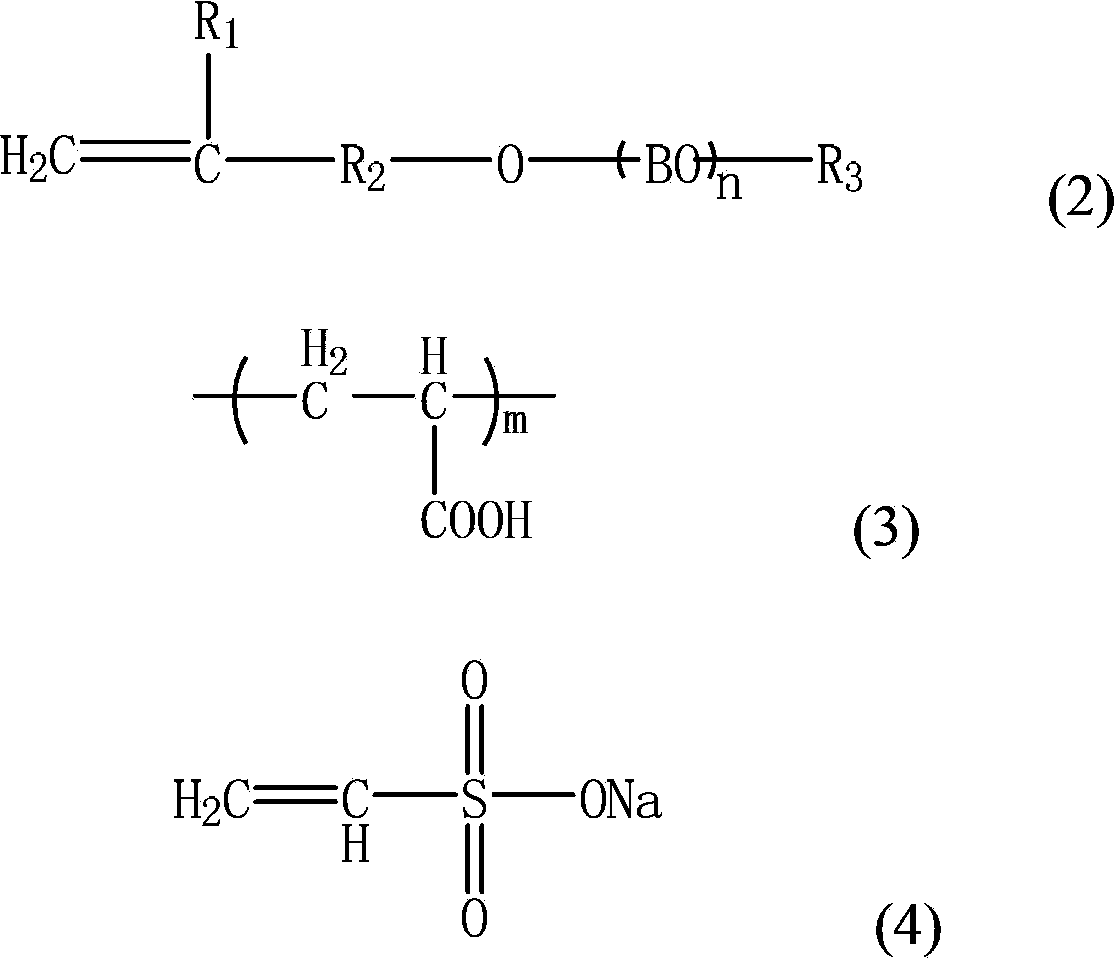

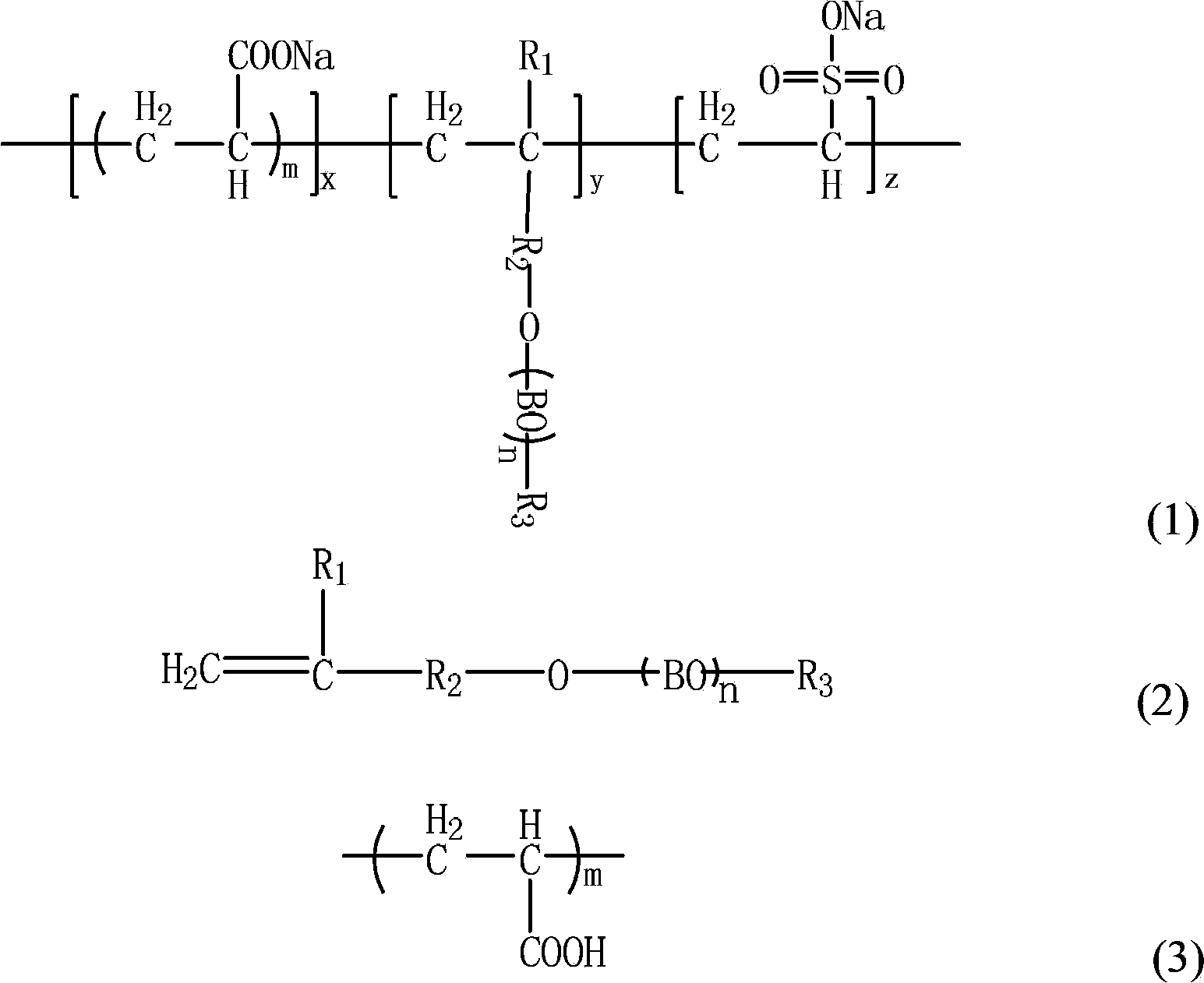

Method used

Image

Examples

Synthetic example

[0037] In a 1000mL four-necked flask equipped with mechanical stirring, a temperature controller, and a dripping device, add 240mL of deionized water and 1.33mL of ammonium persulfate aqueous solution with a mass concentration of 100g / L into the reactor, stir well, and then add 2.22mL of acrylic acid and 0.15mL of isopropanol, stir and raise the temperature, keep the temperature at 60-65°C, start to drop 17.78mL of acrylic acid and 1.33mL of ammonium persulfate aqueous solution with a mass concentration of 100g / L at the same time, and finish the dropwise addition in 20 minutes.

[0038] In a specific embodiment, the compound C is sodium ethyleneoxysulfonate. The above compound C can be purchased from the market.

[0039] In another embodiment, the present invention provides a kind of preparation method of polycarboxylate superplasticizer for high mud-containing concrete, the method comprises the following steps:

[0040] 1) Add deionized water and the first part of ammonium p...

Embodiment 1

[0054] In a 1000mL four-necked flask equipped with mechanical stirring, a temperature controller, and a dripping device, add 240mL of deionized water and 1.33mL of ammonium persulfate aqueous solution with a mass concentration of 100g / L into the reactor, stir well, and then add 2.22mL of acrylic acid and 0.15mL of isopropanol, stir to raise the temperature, keep the temperature at 60-65°C, start to drop 17.78mL of acrylic acid and 1.33mL of ammonium persulfate solution with a mass concentration of 100g / L at the same time, and finish the dropwise addition in 20 minutes. Add 90g of compound A1 (2-vinyloxy alcohol polyoxyethylene ether, ethylene oxide addition number 22) into the reactor, maintain the temperature at 60-65°C, and start adding ethyleneoxy sodium sulfonate and A solution consisting of a mixed solution of thioglycolic acid (17.55g sodium ethyleneoxysulfonate, 1.26g thioglycolic acid dissolved in 45.1g deionized water) and 21mL of ammonium persulfate aqueous solution w...

Embodiment 2

[0057] In a 1000mL four-neck flask equipped with mechanical stirring, a temperature controller, and a dripping device, add 240mL of deionized water and 2.39mL of ammonium persulfate aqueous solution with a mass concentration of 100g / L into the reactor, stir well, and then add 4mL of acrylic acid and 0.27mL of isopropanol were stirred to raise the temperature, and the temperature was kept at 60-65°C. At the same time, 32mL of acrylic acid and 2.39mL of ammonium persulfate solution with a mass concentration of 100g / L were added dropwise, and the dropwise addition was completed in 20 minutes. Add 180g of compound A2 (allyl alcohol polyoxyethylene ether, ethylene oxide addition number 50) into the reactor, maintain the temperature at 60-65°C, and start to dropwise add sodium ethyleneoxysulfonate and mercaptoacetic acid simultaneously. A solution composed of a mixed solution (11.70g sodium ethyleneoxysulfonate, 1.04g mercaptoacetic acid dissolved in 22.28g deionized water) and 17.23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com