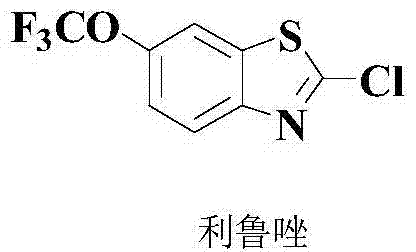

Synthetic method of 2-aryl benzothiazole compounds

A technology for the synthesis of benzothiazoles and methods, applied in the field of synthesis of 2-arylbenzothiazoles, achieving the effects of low temperature, good research value and potential, good reactivity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

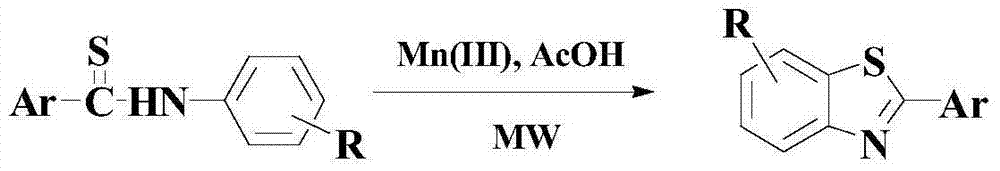

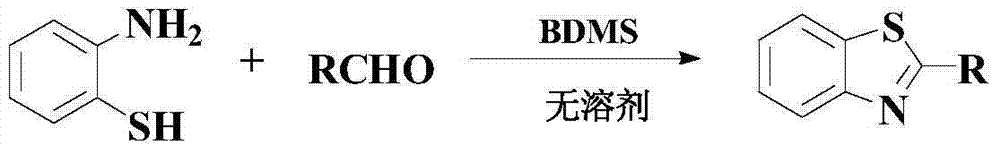

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: the synthesis of 2-phenylbenzothiazole

[0052]

[0053] To 50mL solvent water, add 10mmol o-aminothiophenol and 10mmol benzoylformic acid, mix well, then add 0.5mmol catalyst Cu(OTf) 2 and 10 mmol NaOH, heated to 100° C. and reacted at this temperature for 3 hours. After the reaction, the reaction system was cooled to room temperature, the solvent was evaporated under negative pressure, and the residue was purified by flash column chromatography (n-hexane / ethyl acetate, the volume ratio of the two was 1:1) to obtain the target product 2-phenyl Benzothiazole, yield 94.3%, purity 98.3% (HPLC).

[0054] Melting point: 115-116°C;

[0055] NMR: 1 H NMR (500MHz, CDCl 3 )δ8.11-8.08(m,3H),7.91(d,J=8.0Hz,1H),7.52-7.49(m,4H),7.41-7.38(m,1H);

[0056] 13 C NMR (125MHz, CDCl 3 ) δ 168.0, 154.1, 135.0, 133.6, 130.9, 129.0 (2C), 127.5 (2C), 126.3, 125.2, 123.2, 121.6.

Embodiment 2

[0057] Embodiment 2: the synthesis of 2-p-tolylbenzothiazole

[0058]

[0059] To 50mL solvent water, add 10mmol o-aminothiophenol and 20mmol p-toluoylformic acid, mix well, then add 1mmol catalyst Cu(OTf) 2 and 20mmol NaOH, heated to 90°C and reacted at this temperature for 5 hours. After the reaction, the reaction system was cooled to room temperature, and the solvent was evaporated under negative pressure, and the residue was purified by flash column chromatography (n-hexane / ethyl acetate, the volume ratio of the two was 2:1) to obtain the target product 2-p-toluene Base benzothiazole, yield 95.9%, purity 98.7% (HPLC).

[0060] Melting point: 86-87°C;

[0061] NMR: 1 H NMR (500MHz, CDCl 3 )δ8.07(d,J=8.5Hz,1H),7.99(d,J=8.5Hz,2H),7.89(d,J=8.0Hz,1H),7.50-7.47(m,1H),7.39- 7.30(m,1H),7.30(d,J=8.0Hz,2H),2.43(s,3H);

[0062] 13 C NMR (125MHz, CDCl 3 ) δ 168.2, 154.1, 141.4, 134.9, 130.9, 129.7 (2C), 127.4 (2C), 126.2, 124.9, 123.0, 121.5, 21.5.

Embodiment 3

[0063] Embodiment 3: the synthesis of 2-p-methoxyphenylbenzothiazole

[0064]

[0065] To 50mL solvent water, add 10mmol o-aminothiophenol and 30mmol p-methoxybenzoylformic acid, mix well, then add 1.5mmol catalyst Cu(OTf) 2 and 30mmol NaOH, heated to 80°C and reacted at this temperature for 7 hours. After the reaction, the reaction system was cooled to room temperature, and the solvent was evaporated under negative pressure, and the residue was purified by flash column chromatography (n-hexane / ethyl acetate, the volume ratio of the two was 3:1) to obtain the target product 2-p-methanol Oxyphenylbenzothiazole, yield 84.6%, purity 99.1% (HPLC).

[0066] Melting point: 121-123°C;

[0067] NMR: 1 H NMR (500MHz, CDCl 3 )δ8.05-8.02(m,3H),7.87(d,J=8.5Hz,1H),7.47(t,J=7.0Hz,1H),7.35(t,J=7.0Hz,1H),6.99( d,J=9.0Hz,2H),3.87(s,3H);

[0068] 13 C NMR (125MHz, CDCl 3 ) δ 167.8, 161.8, 154.1, 134.8, 129.0 (2C), 126.3, 126.1, 124.7, 122.7, 121.5, 114.3 (2C), 55.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com