Myogenic Healing Cream

A healing ointment and myogenic technology, applied in ointment delivery, drug combination, plant raw materials, etc., can solve problems such as many side effects and poor healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

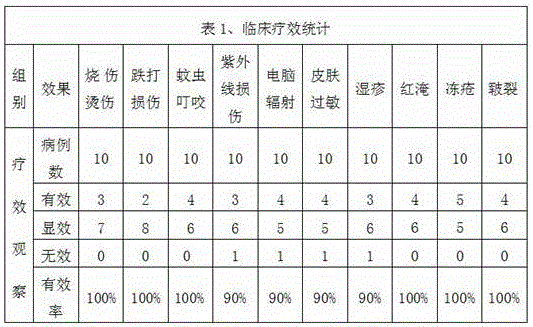

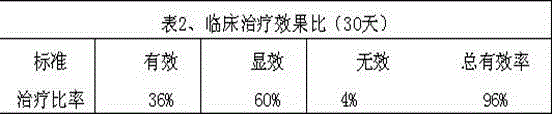

Examples

Embodiment 1

[0085] Shengji Healing Cream, made of the following raw materials: 200 grams of sesame oil, 20 grams of vital energy, 10 grams of vitamin E, 25 grams of trehalose, 5 grams of allantoin, 5 grams of beeswax, 50 grams of glycerin, calcium hydroxide 1 gram.

Embodiment 2

[0087] Shengji Healing Cream, made of the following raw materials: 200 grams of sesame oil, 20 grams of vital energy, 10 grams of vitamin E, 25 grams of trehalose, 5 grams of allantoin, 5 grams of beeswax, 50 grams of glycerin, calcium hydroxide 1 gram, stearic acid 10g, monoglyceride 15g, C16-18 alcohol 15g, emulsifier A-165 15g, propylene glycol 50g, simethicone 10g, MAPK-50 emulsifier 35g, Nipole 1 gram of gold propane, 1.5 grams of methyl paraben, 1.5 grams of essence, 2 grams of LGP antibacterial agent, 528 grams of deionized water. Make 1000 grams of paste.

[0088] Note: Calcium hydroxide can be made into an aqueous solution.

[0089] Or calcium hydroxide can be when 20 ℃, add the calcium hydroxide aqueous solution by the ratio of 0.17 gram calcium hydroxide adding 100 gram deionized waters, fully stir, dissolve, leave standstill, get supernatant for subsequent use.

Embodiment 3

[0091] Production process of Shengji Healing Cream:

[0092] Phase A (oil phase): sesame oil, stearic acid, monoglyceride, C16-18 alcohol, emulsifier A-165, beeswax, simethicone, propylene glycol, propylparaben.

[0093] Phase B (water phase): deionized water, calcium hydroxide, trehalose, allantoin, glycerin, methylparaben, MAPK-50 emulsifier.

[0094] Phase C: Life power factor, natural vitamin E, LGP antibacterial agent, essence.

[0095] (1) Weigh the various raw and auxiliary materials of Phase A, Phase B and Phase C respectively in proportion,

[0096] (2) Put phase A and phase B into the oil and water pot respectively for heating in a water bath, dissolve both phases A and B, stir evenly, put phase A into the vacuum homogeneous emulsification pot first, and then put phase B Slowly add to phase A, heat, stir, homogenize, and emulsify in a water bath in a vacuum homogeneous emulsification pot. The emulsification temperature is 85 degrees, and the emulsification time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com