Method for recycling reclaimed water in circulating cooling water system

A technology for circulating cooling water and reclaimed water, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc., can solve problems such as pipeline corrosion, reduce difficulty and reduce water eutrophication risk, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0047] Add 990g of acrylic acid, 510g of 2'-acrylamide-2-methylpropanesulfonic acid, 3500g of deionized water, 90g of ammonium persulfate into the reaction kettle, pass high-purity nitrogen to remove oxygen for 0.5h, and continue to pass nitrogen until the thermocouple in the polymerization kettle The temperature began to rise, the reaction temperature was 80°C, and the reaction time was 2h. After the end of the polymerization reaction, cool to obtain a mass concentration of 30% acrylic acid / 2'-acrylamide-2-methylpropanesulfonic acid polymer solution. The limiting viscosity of the acrylic acid / 2'-acrylamide-2-methylpropanesulfonic acid polymer at 30°C is 0.095dL / g.

Embodiment 1

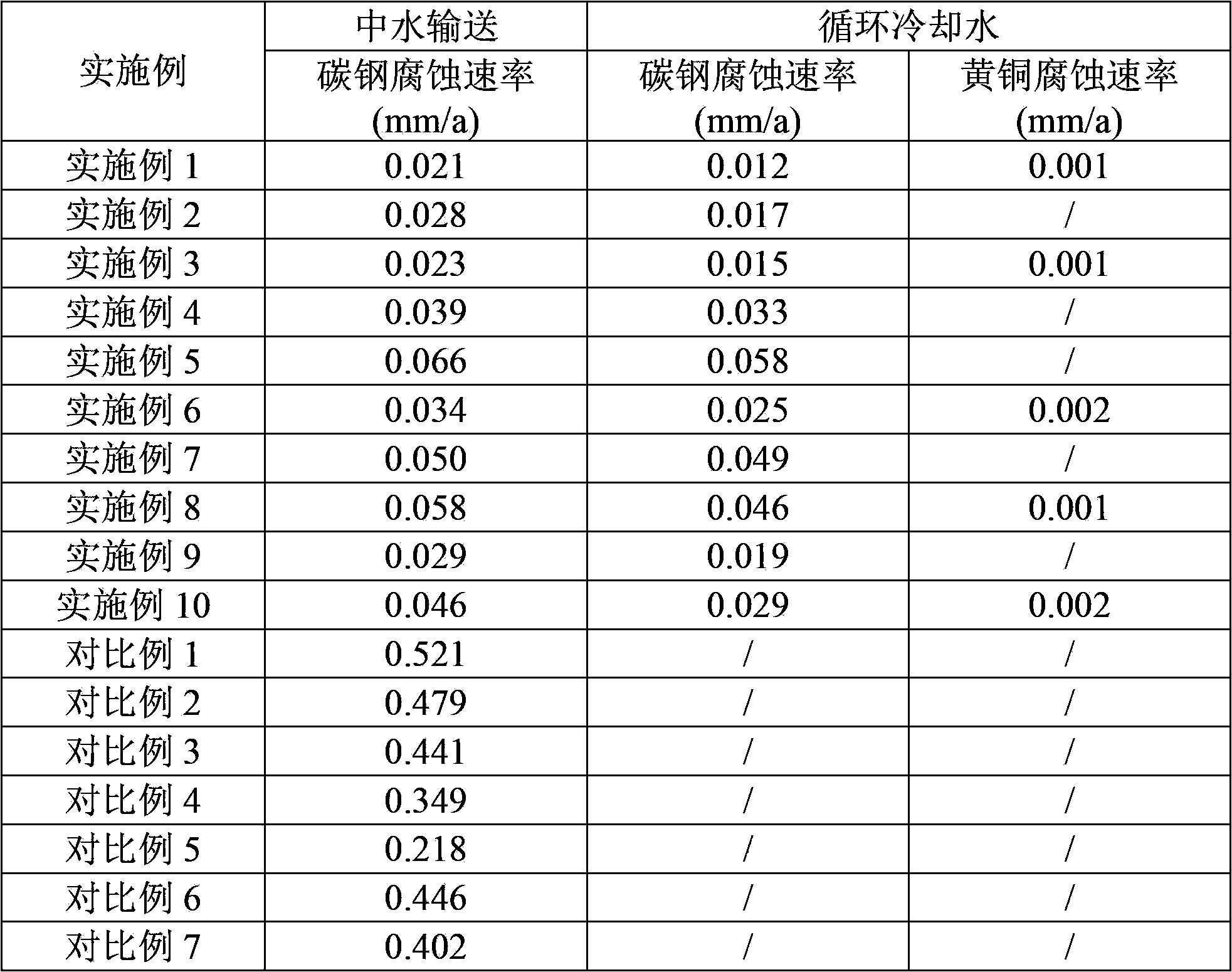

[0049] Take reclaimed water 1 as the test water, add slaked lime to it, and take per liter of reclaimed water as the basis, slaked lime (as CaCO 3 The amount of addition is 120mg / L, and the filtered supernatant is added with sodium silicate (n=3.0) (based on SiO 2 Calculated) 30mg / L, in order to carry out the corrosion evaluation test of reclaimed water pipeline transportation. Concentrate the above water by 5.5 times, add the acrylic acid / 2'-acrylamide-2-methylpropanesulfonic acid polymer solution prepared in Preparation Example 1 to polymerize the acrylic acid / 2'-acrylamide-2-methylpropanesulfonic acid The effective concentration of the substance is 15mg / L and 3.0mg / L of mercaptobenzothiazole is added to carry out the corrosion evaluation test of the circulating cooling water system. The results of the two tests are shown in Table 2.

preparation example 2

[0051] Add 1200g of acrylic acid, 300g of isoprene sulfonic acid, 3500g of deionized water, 90g of ammonium persulfate into the reaction kettle, pass high-purity nitrogen to remove oxygen for 0.5h, continue to pass nitrogen until the thermocouple in the polymerization kettle starts to heat up, and the reaction temperature is 80 ℃, reaction time 2h. After the polymerization reaction is completed, cool to obtain an acrylic acid / isoprene sulfonic acid polymer solution with a mass concentration of 30%. The measured intrinsic viscosity of acrylic acid / isoprene sulfonic acid at 30°C is 0.069 dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com