Method for preparing oxidation-resistant composite coating for carbon ceramic brake disc

A technology for composite coatings and brake discs, applied in the field of preparation of anti-oxidation composite coatings, can solve the problems of high cost of preparation materials, weak anti-oxidation ability, complicated preparation process, etc., and achieve simple preparation process and strong resistance to seawater erosion , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

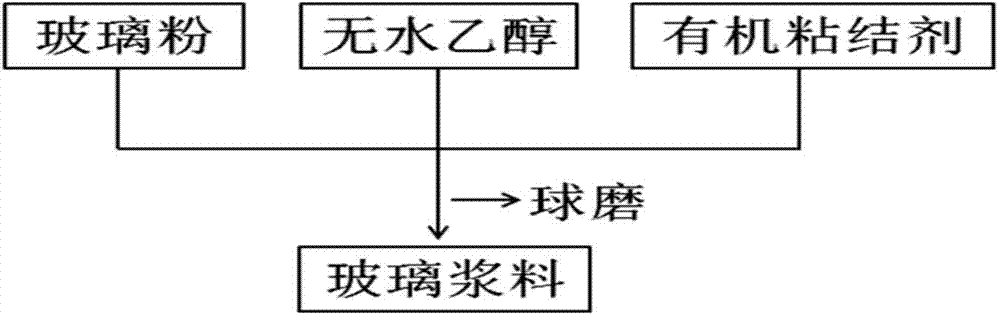

[0033] Preparation of glass powder slurry: make an organic silane binder with anhydrous alcohol and organosilane in a mass ratio of 50:15; combine organosilane binder, cordierite powder and glass powder in a mass ratio of 3:1 : 1 ratio mixing, ball milling to get a uniform glass powder slurry.

[0034] The organosilane is polyazinosilane, polysiloxane or polycarbosilane.

[0035] The cordierite powder is 2MgO·2Al with a softening point of 1200-1400°C 2 o 3 ·5SiO2 2 pink.

[0036] The glass powder is borosilicate glass powder with a softening point of 500-700°C.

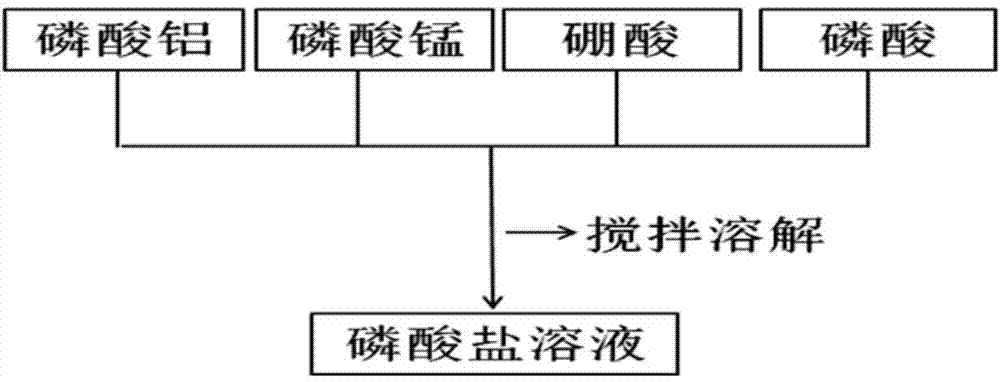

[0037] Preparation of phosphate solution: Dissolve aluminum phosphate, manganese phosphate, boric acid and phosphoric acid in water with a molar ratio of 2:1:1:20, and the mass ratio of water to phosphoric acid is 30:25 to obtain a phosphate solution, which is sealed for use .

[0038] Step 1: Preparation of carbon ceramic brake disc samples:

[0039] The processed carbon-ceramic brake disc samples were ultraso...

Embodiment 2

[0046]Preparation of glass powder slurry: polyvinyl alcohol was dissolved in distilled water to prepare a polyvinyl alcohol aqueous solution with a concentration of 5%; the polyvinyl alcohol aqueous solution, cordierite powder and glass powder were mixed in a mass ratio of 9:2:1, and the A uniform glass powder slurry was obtained by ball milling.

[0047] The polyvinyl alcohol is substituted with sodium carboxymethylcellulose.

[0048] The cordierite powder is 2MgO·2Al with a softening point of 1200-1400°C 2 o 3 ·5SiO2 2 pink.

[0049] The glass powder is borosilicate glass powder with a softening point of 500-700°C.

[0050] Preparation of phosphate solution: Dissolve aluminum phosphate, manganese phosphate, boric acid and phosphoric acid in water with a molar ratio of 3:2:2:30, and the mass ratio of water to phosphoric acid is 35:25 to obtain a phosphate solution, which is sealed for use .

[0051] Step 1: Preparation of carbon ceramic brake disc samples

[0052] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com