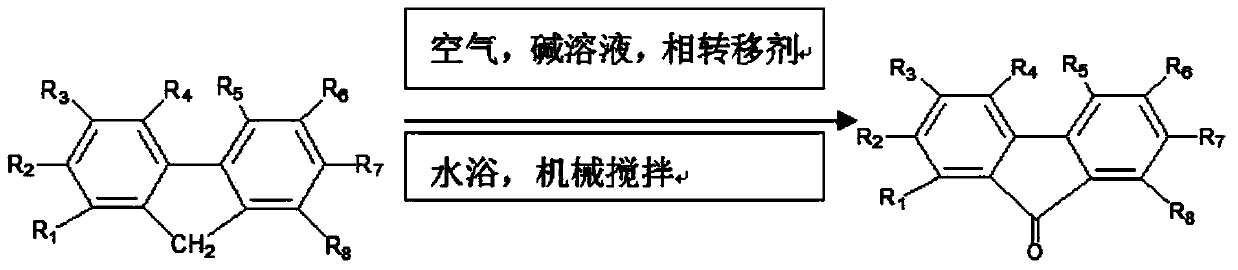

Method for preparing high-purity 9-fluorenone from high-purity fluorene

A high-purity, fluorenone technology, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of large solvent loss, undisclosed types of quaternary ammonium salts, and high reaction temperature, so as to improve utilization efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Take 15g of the above refined fluorene into a 250mL three-necked flask, add 45mL xylene, 0.20g tetrabutylammonium chloride, 6g NaOH and 9mL water, heat in a 40℃ water bath, control the mechanical stirring rate to 200r / min, and pass clean air 200×2mL / min. During the reaction, the conversion rate of fluorene was monitored by thin layer chromatography. After 3.5 hours of reaction, the raw material point disappeared, and the reaction was continued for 0.5 hours to stop the reaction. The reaction solution was transferred to a separatory funnel for liquid separation, and the organic layer was taken and washed with water to neutrality. Gas chromatography detection showed 100% conversion of fluorene, with only one absorption peak of fluorenone.

Embodiment 2

[0052] Except that 0.30g of tetrabutylammonium hydrogen sulfate is used instead of 0.20g of tetrabutylammonium chloride, the others are the same as in Example 1. After 3 hours of reaction, TLC showed that the fluorene spots of the raw material disappeared completely, and the reaction was continued for 0.5 hours to stop the reaction. Chromatographic analysis of the organic layer showed 100% conversion of fluorene, with only one absorption peak of fluorenone.

Embodiment 3

[0054] Except that 0.30g of tetrabutylammonium bromide replaces 0.20g of tetrabutylammonium chloride, the others are the same as in Example 1. After 3.5 hours of reaction, TLC showed that the fluorene spots of the raw material disappeared completely, and the reaction was continued for 0.5 hours to stop the reaction. Chromatographic analysis of the organic layer showed 100% conversion of fluorene, with only one absorption peak of fluorenone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com