Acoustic resonance type thermally-driven travelling wave thermo-acoustic refrigerating system

A traveling wave thermoacoustic and acoustic resonance technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as inconsistency of double-acting systems, no solution proposed, viscosity loss, etc., to reduce irreversible conversion Effects of heat loss, improved energy efficiency, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

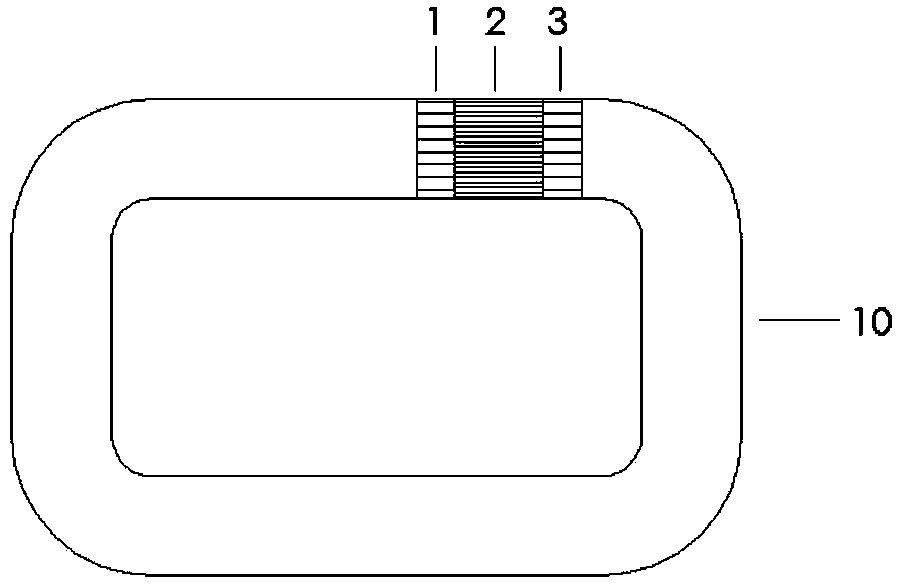

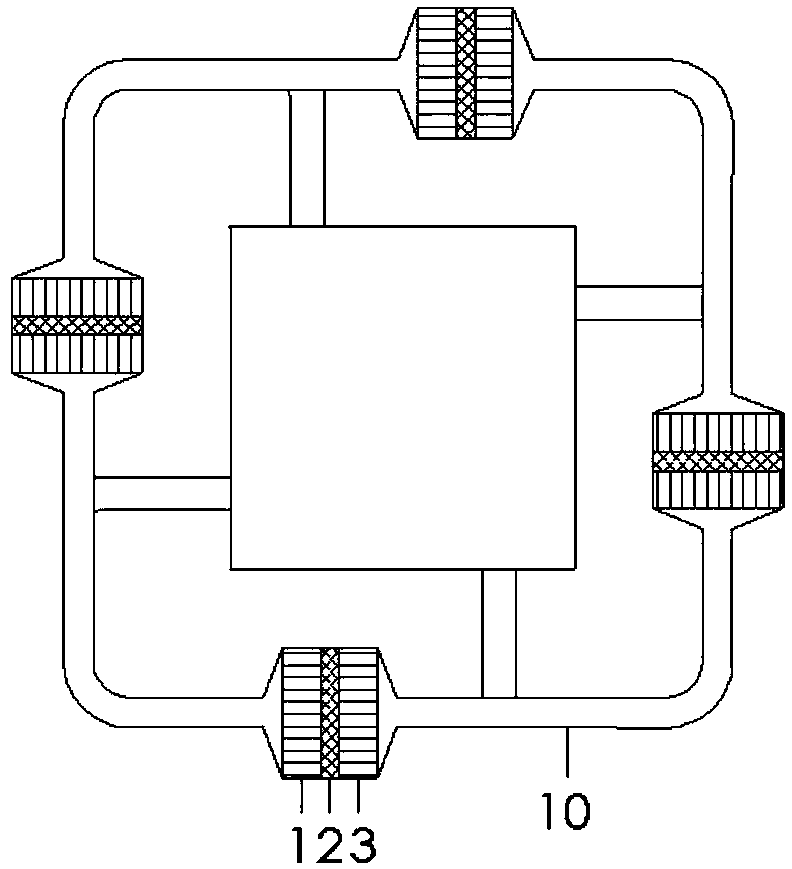

[0043] Figure 5 It is a structural schematic diagram of an acoustic resonance type heat-driven traveling wave thermoacoustic refrigeration system (Example 1) of the present invention; Figure 5 As shown, the thermoacoustic engine connected in series, the pulse tube refrigerator and the corresponding resonance tube constitute a thermoacoustic unit of the system. The loop acoustic resonance refrigeration system in this embodiment 1 is composed of three such thermoacoustic units connected end to end. As a result, the phase difference of the volume flow rate at the first and last ends of each thermoacoustic unit is 120°

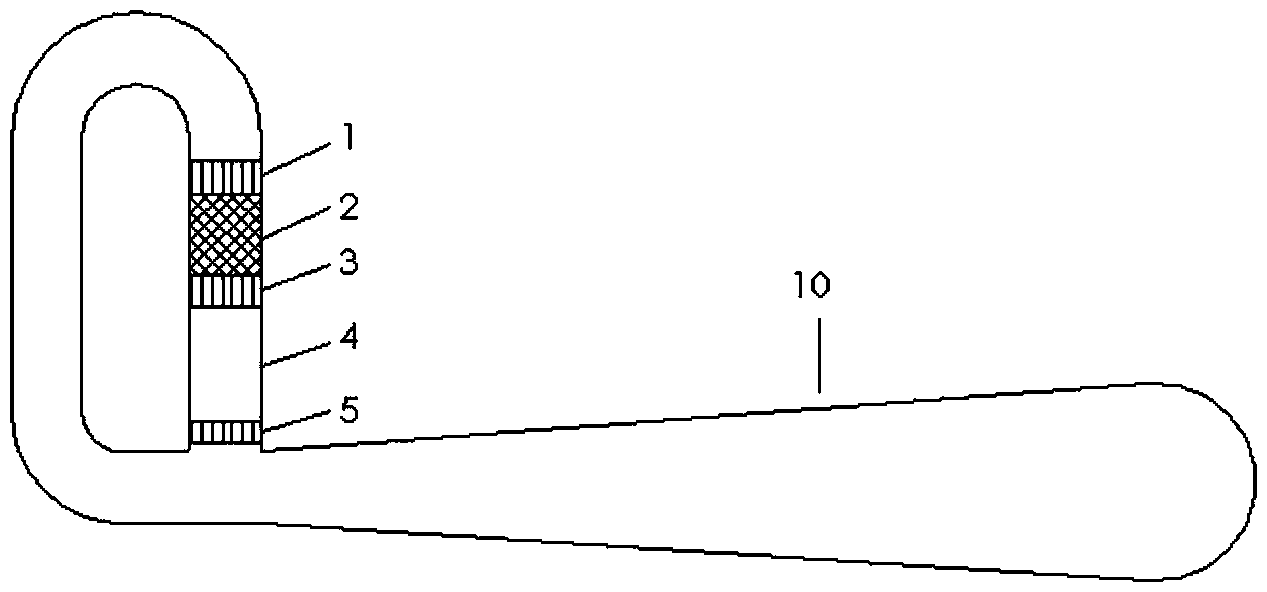

[0044] Each thermoacoustic unit is composed of the first main room temperature end heat exchanger 1, the first regenerator 2, the hot end heat exchanger 3, the first thermal buffer tube 4, and the second main room temperature end heat exchanger connected in series. 5, the second regenerator 6, the cold end heat exchanger 7, the second heat buffer pipe 8, the se...

Embodiment 2

[0048] Image 6 It is a structural schematic diagram of a loop acoustic resonance refrigeration system (embodiment 2) of the present invention. Such as Image 6 As shown, the thermoacoustic engine connected in series, the pulse tube refrigerator and the corresponding resonant tube constitute a thermoacoustic unit of the system. The loop acoustic resonance refrigeration system in this embodiment 2 is composed of 4 such thermoacoustic units connected end to end. become.

[0049] In Embodiment 2, the phase difference of the volumetric flow rates at both ends of each thermoacoustic unit is 90°. Heat the heat exchanger 3 at the hot end, the first main room temperature heat exchanger 1, the second main room temperature heat exchanger 5 and the second room temperature heat exchanger 9 are fed with cooling water to maintain the room temperature range, when the hot end After the temperature gradient between the heat exchanger 3 and the first main room temperature heat exchanger 1 re...

Embodiment 3

[0051] Figure 7 It is a structural schematic diagram of a loop acoustic resonance refrigeration system (embodiment 3) of the present invention. Such as Figure 7 As shown, the thermoacoustic engine connected in series, the pulse tube refrigerator and the corresponding resonant tube constitute a thermoacoustic unit of the system. The loop acoustic resonance refrigeration system of this embodiment 3 is composed of 6 such thermoacoustic units connected end to end. become.

[0052] In Embodiment 3, the phase difference of the volumetric flow rates at both ends of each thermoacoustic unit is 60°. Heat the heat exchanger 3 at the hot end, the first main room temperature heat exchanger 1, the second main room temperature heat exchanger 5 and the second room temperature heat exchanger 9 are fed with cooling water to maintain the room temperature range, when the hot end After the temperature gradient between the heat exchanger 3 and the first main room temperature heat exchanger 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com