A coal-fired power plant flue gas recovery system and energy-saving water-saving ultra-clean discharge method

A heat recovery system, coal-fired power plant technology, applied in the direction of combustion method, combustion equipment, fuel supply, etc., can solve the problems of not using low-temperature economizer to cool down, unable to separate water, and generate dust, so as to avoid corrosion of chimneys and Emitting white smoke, which is beneficial to natural lifting and diffusion, and reduces the moisture content of the flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

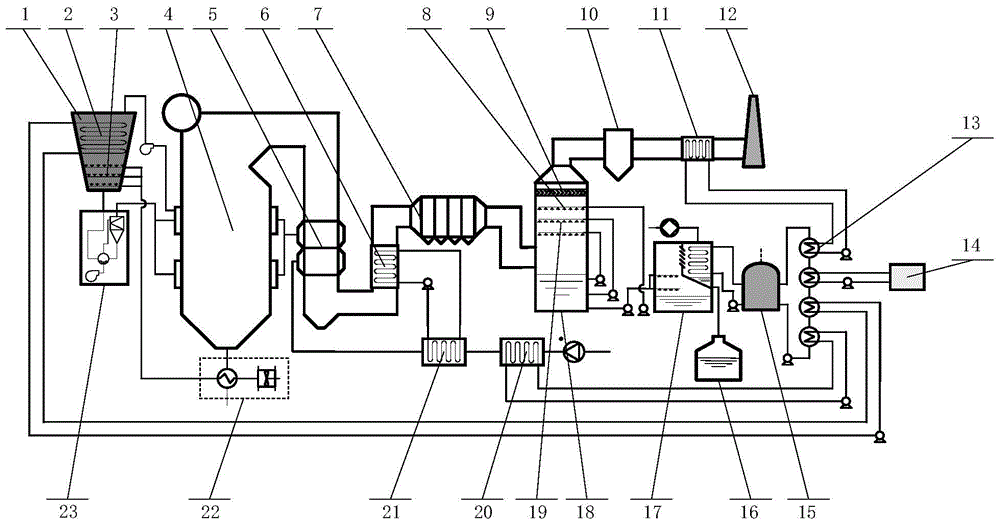

[0051] like figure 1 As shown, the present invention is based on conventional coal-fired power plant boiler furnace, burner, flue air system, air preheater, pulverizing system, coal bunker, slagging system, electrostatic precipitator, desulfurization tower, wet electrostatic precipitator , adding low-temperature economizer, first-level air heater, second-level air heater, last-stage spraying device, vacuum flash evaporation flash-condensation device, low-temperature heat pump heat exchange device, waste heat utilization heat exchanger, first-level coal drying device, Secondary coal drying unit, flue gas reheat heat exchanger, and piping and pumps or fans connecting these units. Among them, the outlet of the boiler furnace is connected to the boiler flue air system, and the output pipe behind the air preheater of the boiler flue air system is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com